The Art Behind the Arc: Celebrating Precision and Perfection in Welding

Welding is often viewed through the lens of utility, associated with heavy industry, pipelines, and construction projects. But what many don’t realize is that it’s also an art form — one that requires precision, control, and a deep understanding of the materials at hand. The image above exemplifies the finesse and craftsmanship that welders bring to their work, especially when it comes to achieving perfection with a welding arc.

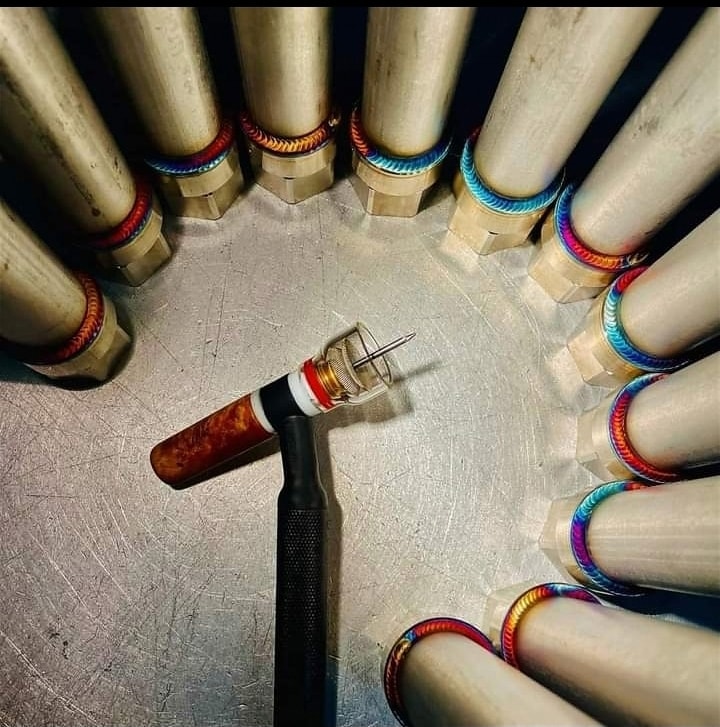

The photograph captures a TIG (Tungsten Inert Gas) torch surrounded by a ring of beautifully welded joints, each seam displaying a rainbow-like color pattern. This isn’t just about making connections; it’s about achieving mastery in the welding process. The controlled heat, clean filler metal application, and the steady hand required to produce those vibrant colors are a testament to the skill and patience of the welder. Let’s dive deeper into what it takes to create such a visually stunning weld and why the welding arc is at the heart of this process.

The Arc: The Foundation of a Perfect Weld

The arc is the heart of welding. It’s where the magic happens — the point where electricity and heat converge to fuse metals together. In TIG welding, the arc is established between a non-consumable tungsten electrode and the workpiece. The resulting plasma arc can reach temperatures exceeding 6,000°C (10,832°F), providing the precise heat needed to create a controlled melt pool. The control and stability of this arc are crucial for producing clean, high-quality welds.

But welding with an arc isn’t just about joining metals. The way the arc is manipulated, the speed of travel, and the filler metal application all play a role in creating welds that are both structurally sound and aesthetically pleasing. The concentric rings in the image are a product of perfectly balanced arc manipulation, meticulous hand coordination, and mastery over variables like amperage and travel speed.

The Colors of Heat: A Welder’s Signature

The vibrant colors seen in the welds — ranging from gold and purple to blue and teal — are caused by the oxidation of the metal surface at high temperatures. The appearance of these colors is not accidental; they are indicators of a controlled thermal environment. Achieving these hues requires an exact temperature range and precise shielding gas coverage to prevent contamination.

For experienced welders, these colors are a mark of pride, a visual representation of their skill. Each weld is a signature, a testament to their ability to handle the heat and control the arc. A perfectly formed weld with consistent coloring is more than just functional; it’s a masterpiece.

Beyond Functionality: When Welding Meets Art

The idea of welding as an art form may seem unconventional, but it’s evident in the image above. The symmetry, uniformity, and vibrant colors are characteristics that go beyond necessity. This is where welding transcends its industrial roots and becomes a form of artistic expression. It’s a blend of science and art — understanding metallurgy, thermodynamics, and physics while applying these principles with the precision of an artist’s brush.

Producing welds like the ones seen in this photograph isn’t just a technical achievement. It’s the result of countless hours of practice, meticulous attention to detail, and a passion for perfection. Each bead, each ripple, and each layer of color tells a story of dedication and skill, something that only comes with experience.

The Takeaway: Celebrating the Welders Behind the Arc

Behind every perfect weld is a welder who has honed their craft, mastered their equipment, and poured their passion into their work. The beauty of welding is that it’s both functional and expressive, and images like this one remind us that every arc struck is an opportunity for creating something unique.

So, the next time you see a well-crafted weld with rainbow hues, remember: it’s more than just metal fused together. It’s a symbol of the artistry, precision, and dedication that define the world of professional welding. A salute to the artisans behind the arc, who turn every weld into a masterpiece.

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders