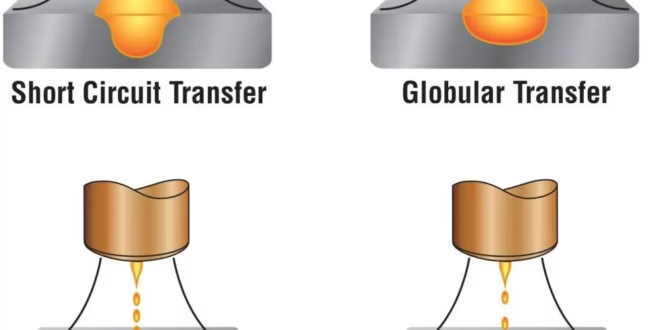

Spray vs Short-Circuit vs Pulsed MIG What Are MIG Transfer Modes? MIG transfer modes describe how molten filler metal moves from the wire electrode into the weld pool during MIG (GMAW) welding. The selected transfer mode directly affects: Heat input Penetration Spatter Bead appearance Welding position capability The three main …

Read More »

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders