Welding Joints and their Types

Introduction

Welding is a process of joining two or more metals. Welding is an ancient discovery of human beings. It has applications in almost every field of life. With the advancement in technology, advanced welding is being introduced day by day. Here in this article, we will be thronging light on welding joints and their types. There are many different types of welding joints being used based on the type of joint. A welding joint or weld joint is an edge or joining point of two joining metals. The welding joint is the place where the melted metal is joined to the base metal. The selection of the correct weld joint is very important, it is wrong weld joint is selected; it would loss of money, time, energy, and resources. It requires practical and technical training hoping for satisfactory results. It is the great responsibility of the welder to choose the correct and appropriate weld joint and welding procedures. For high quality and accurate results, correct design and particular weld joints are necessary. A welder should have knowledge of fundamental joint design and welding procedures.

Types of Welding Joints

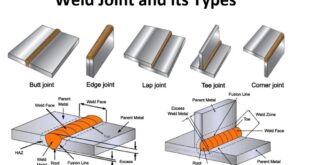

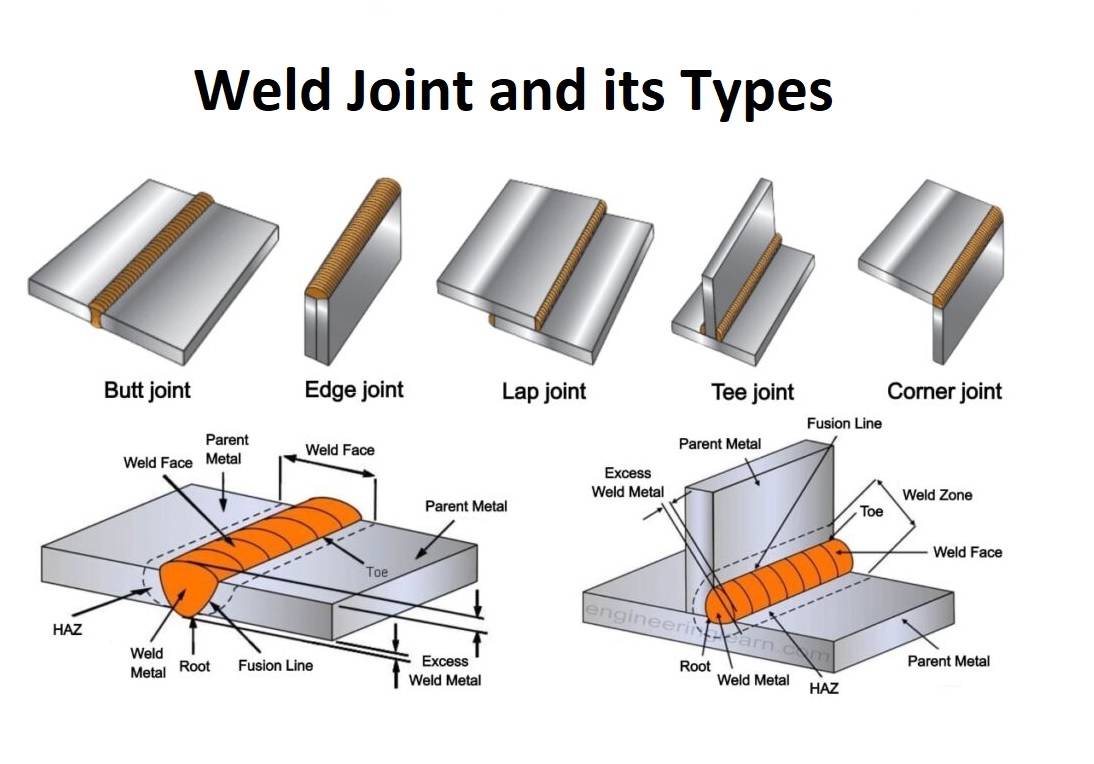

There are 5 major types of weld joints based on the type of materials to be joined:

- Butt joint

The butt joint is also known as the square groove weld joint. It is the most simple and mostly used weld joint. It is performed on two flat pieces of metal that are placed parallel to each other. An angle of 135° – 180° is made between two metals. It is cheap and efficient for joining pipes, valves, and fittings of pieces of equipment. There are many styles that can be used while doing butt welding.

- Square groove weld

- V groove weld

- Bevel weld

- Flare V groove weld

- U groove weld

- J groove weld

- Lap joint

Lap weld is another important joint and it is performed on two metal pieces placed on top of each other i.e., in an overlapping pattern. And the overlap pieces made an angle of 0°-5°. In a lap joint, there is no restriction on metal thickness, it can be of any thickness. It is used in joining sheet metal. It can be done on one or two sides of metal. There are many styles of lap joints.

- Fillet weld

- J groove weld

- Bevel groove weld

- Plug weld

- Slot weld

- Spot weld

- Corner joint

A corner joint is a type of weld joint where the two metals make a 90°or right angle i.e., an L-shape joint. The metal pieces make an angle from 30°- 130°. It has applications in the metal sheet industry. It is very difficult to make maintain correct alignment because the angle is a right angle. It is used in making boxes, frames, and fabrication of sheet metal pieces. A corner joint or L-shaped joint has many styles to be applied.

- Square groove weld

- Fillet weld

- J groove weld

- V groove weld

- Flare V groove weld

- Spot weld

- Edge weld

- Corner flanging edges weld

- Tee joint or T joint

T joint is a type of joint, where two metal pieces are placed on each other making an angle of 90° or a right angle in a T shape. It is used in the structural industry. It mostly uses fillet or groove weld on both sides of the vertical piece. It has application in plate-to-plate or branch connections. There are many styles of T joints.

- Fillet

- J groove type weld

- Bevel groove weld

- Plug weld

- Slot weld

- Flare V groove weld

- Edge joint welding

An edge joint is a type of joint where two metal pieces are placed such that the edges of both are even. One or both plates may be formed by bending them at an angle. In this weld joint, the metal pieces are placed together such that the stresses are distributed. It is used in joining sheet metal parts, especially corner making. The following are the main styles used in edge joint welding.

- Bevel groove weld

- V groove weld

- J groove weld

- U groove weld

- Corner flange weld

- Edge flange weld

FAQs

What is the most common used weld joint?

The most common used weld joint is the butt joint, where two pieces of metal are joined end-to-end.

Which weld joint is strongest?

It is not accurate to say that one type of joint is stronger than the others, as the strength of a weld joint depends on various factors, including the quality of the weld, the skill of the welder, and the properties of the metal being welded.

How many types of joints are used for welding generally?

There are several types of joints used for welding, including butt, corner, edge, lap, and T-joints.

What is the easiest type of welding joint to perform?

The easiest type of welding joint to perform would depend on the welder’s skill level and experience, as well as the type of welding being performed. A butt joint, for example, is generally considered to be one of the easiest types of joints to weld.

Which welding joint is the weakest?

It is not accurate to say that any one joint is weakest. The strength of a joint depends on the quality of the weld, the skill of the welder, and the properties of the metal being welded.

What is the cleanest type of welding?

Gas Tungsten Arc Welding (GTAW) is considered one of the cleanest types of welding, as it does not produce a lot of smoke or spatter.

Which welding has the highest efficiency?

Gas Tungsten Arc Welding (GTAW) is considered one of the most efficient types of welding as it produces high-quality welds with minimal distortion.

What is the safest metal to weld?

Aluminum is considered the safest metal to weld as it does not produce toxic fumes, it is relatively lightweight and low heat input reduces the chance of warping.

What material is easiest to weld?

Mild steel is considered one of the easiest materials to weld due to its good weldability and relatively low cost.

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders