Innovations in Welding Technology: A Look at the Latest Developments

Introduction

Welding is a vital process that is used in a wide range of industries, including construction, automotive, and manufacturing. It allows for the permanent joining of metal pieces, creating strong and durable structures. As such, welding is an essential part of many products and projects, and its importance cannot be understated.

In recent years, there has been a push for continuous innovation in welding technology. This is necessary in order to improve the efficiency, accuracy, and safety of the welding process. As industries continue to evolve and change, the demand for more advanced welding techniques also grows. In order to meet these needs, it is important for the welding industry to constantly seek out and develop new technologies.

The rise of automation in welding

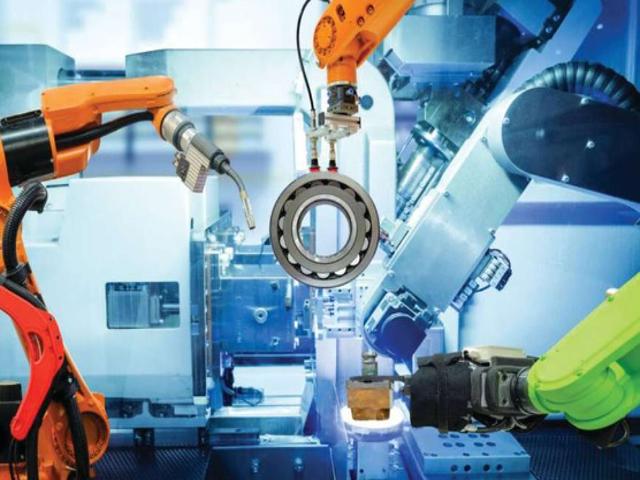

One of the latest developments in welding technology is the increasing use of automation and robots in the welding process. These systems are able to perform complex welding tasks with a high degree of precision, reducing the need for human labor. Automation also helps to increase efficiency, as the robots can work continuously without the need for breaks or rest.

There are numerous benefits to using automation in welding. One of the main advantages is increased efficiency. Robots and automation systems are able to work at a faster pace than humans, which can significantly reduce the time it takes to complete a welding project. Additionally, automation can improve the precision and accuracy of the welding process, as robots are able to follow precise instructions and repeat tasks consistently. This can lead to a higher quality end product.

Automation also has the potential to improve safety in the welding industry. By using robots and automation systems, welders can avoid exposure to the heat and sparks that are generated during the welding process. This can reduce the risk of injuries and accidents on the job. Overall, the use of automation in welding has the potential to significantly improve the efficiency, accuracy, and safety of the process.

Advancements in materials and equipment

There have also been significant advancements in the materials and equipment used for welding. In recent years, new alloys and materials have become available for use in welding, including aluminum and stainless steel. These materials offer a high degree of strength and corrosion resistance, making them ideal for use in a variety of applications.

In addition to new materials, there have been developments in welding equipment as well. For example, laser welding and hybrid welding have gained popularity in recent years. Laser welding uses a high-energy laser beam to fuse together metal pieces, while hybrid welding combines multiple welding techniques, such as laser welding and traditional arc welding. These new welding methods offer increased precision and speed compared to traditional methods, making them particularly useful in industries that require a high level of accuracy.

Overall, the introduction of new materials and the development of advanced welding equipment have greatly improved the efficiency and effectiveness of the welding process. These innovations have allowed for the creation of stronger and more durable structures, and have opened up new possibilities in the welding industry.

The role of virtual reality and simulation in welding training

The use of virtual reality and simulation technology has also had an impact on the welding industry, particularly in the realm of training. These tools allow welders to practice and hone their skills in a safe and controlled environment, without the risk of injury or damage to equipment.

Virtual reality technology can provide a realistic and immersive experience for welders, allowing them to practice in a variety of conditions and environments. Simulation also allows for cost-effective training, as it eliminates the need for expensive materials and equipment. Additionally, simulation allows welders to practice in a variety of conditions, such as extreme temperatures or in hazardous environments, which may not be possible in real life.

The future of welding technology

Looking to the future, it is likely that automation and the use of artificial intelligence will continue to play a significant role in welding technology. There is also potential for new materials and techniques to be developed, which could revolutionize the way in which welding is performed. These advancements will likely help to further improve the efficiency and effectiveness of the welding process, and will allow the industry to adapt to the changing needs of various industries.

Conclusion

In conclusion, the latest developments in welding technology have greatly improved efficiency, accuracy, and safety in the industry. From the introduction of automation and new materials to the use of virtual reality and simulation in training, these innovations have had a significant impact on the way in which welding is performed. It is important for the welding industry to continue to innovate and adapt in order to meet the changing needs of various industries. As technology and techniques evolve, the demand for more advanced welding methods will only continue to grow. By staying at the forefront of innovation, the welding industry can ensure that it is able to meet the needs of its customers and stay competitive in an increasingly technology-driven world.

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders