What Is a Seal Weld?

What Is a Seal Weld?

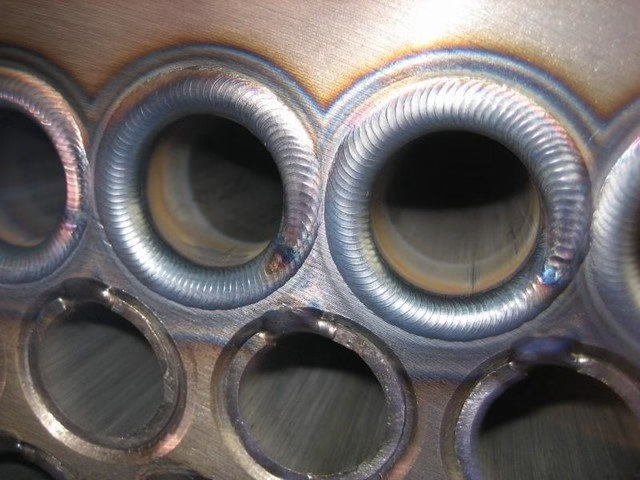

A seal weld is a type of weld applied primarily to prevent the passage of fluids, gases, or contaminants—not to provide structural strength. Unlike load-bearing welds, its role is sealing gaps or joints to prevent leaks, improve corrosion resistance, and in some cases, to enable easier cleaning or preparation of a surface for finishing.

Distinguishing Seal Welds from Structural Welds

While both may look similar, a structural weld is designed to carry loads, resist stress, and form part of the load-bearing skeleton of a structure. A seal weld, in contrast, might be cosmetic or functional in a different way, such as forming a barrier against water or corrosive gases.

Where Seal Welds Are Commonly Found

You’ll typically find seal welds in:

Pipe flanges and vessel covers

HVAC systems

Industrial enclosures

Painted steel components

Galvanized steel joints

Primary Purposes of Seal Welds

Leak Resistance and Containment

Seal welds are widely used to prevent leakage of liquids or gases in mechanical systems, particularly in pressure vessels, pipelines, and tanks. By sealing the joint entirely, they close off paths where fluids could escape.

Corrosion Prevention

A prime use of seal welds is to prevent the ingress of moisture or corrosive agents, which could lead to internal rusting, especially in painted steel structures. By sealing gaps, welders reduce crevice corrosion, where moisture gets trapped.

Facilitating Cleaning and Surface Finishing

Seal welds also create smooth, uninterrupted surfaces, which are easier to clean and sanitize. This is crucial in environments such as food processing plants, where hygiene is paramount.

Galvanizing Support – Preventing Zinc/Pickle Penetration

Before hot-dip galvanizing, seal welds are used to prevent zinc or pickling acid from entering overlapping plates. Otherwise, trapped chemicals could corrode the joint from the inside.

Applications and Practical Use Cases

Mechanical Joints in Pipelines and Tanks

In pressurized systems, seal welds are used to ensure gas-tight or liquid-tight enclosures, supplementing bolted or threaded connections that might leak under vibration or heat cycles.

Structural Steel Fabrication

Steel structures exposed to the elements—like painted staircases or railings—often employ seal welds to prevent “rust bleeding” through the paint.

Food and Pharmaceutical Facilities

Seal welds make equipment easier to sanitize, removing bacterial havens and reducing the risk of contamination.

Nameplates and Labels in Harsh Environments

When affixing stainless steel nameplates on machinery, particularly in high-vibration environments, seal welds ensure the tag stays clean, intact, and legible.

Code Conflicts and Challenges

AWS D1.1-98, Section 2.4.7.5

This section states welds should be interrupted at opposite sides in the same plane at corners. But when welders fully seal such joints, they may inadvertently violate this, introducing hard spots and stress risers.

AWS D1.1, Section 2.4.7.3

Seal welds can remove designed flexibility from joints meant to move or flex. Welding them completely changes the structural behavior, potentially leading to fatigue failure.

AWS D1.1, Section 2.4.7.4

This clause mandates stiffeners should not be cut short unless designed that way. If a seal weld encases the area, it may compromise ductility or induce cracking.

Broader Relevance of These Provisions

Even when AWS D1.1 is not the governing code, engineers should heed these principles. Ignoring them can cause seal welds to do more harm than good.

Creation of Alternate Load Paths

How Seal Welds Can Inadvertently Bear Loads

A common mistake is to apply seal welds where the connection was not intended to share loads, such as bolted joints. This creates parallel load paths, leading to unpredictable stress distribution.

AWS D1.1 Section 2.6.3 on Bolts and Welds

According to AWS D1.1 Section 2.6.3, bolts and welds should not share load-bearing duties unless designed to do so. Seal welding in these locations might weaken the entire connection due to unintended stress fractures.

Example Case: Rock Crusher with Welded Stainless Nameplate

An example is a tub-style rock crusher with a stainless nameplate seal welded into a high-vibration area. Despite the weld being non-structural, it cracked and propagated failure into the base metal, requiring rework.

Consequences of a Lax Attitude Toward Seal Welds

Neglecting Preheat, Heat Input, or Electrode Selection

Some welders treat seal welds as non-critical and skip preheat or proper electrode use. This leads to lack of fusion, porosity, or cracks that compromise the part over time.

Violating AWS D1.1 Table 5.8 Minimum Weld Size

Seal welds must still meet minimum size requirements to avoid rapid cooling and cracking. Skipping these increases the risk of hidden defects.

Real-World Effects: Cracking, Incomplete Fusion, Corrosion

Inconsistent seal welds allow moisture to penetrate, causing rust to form under the seal, which can then crack the weld outward or corrode the joint from the inside.

Inspection Difficulties

How Seal Welds Affect Ultrasonic Testing (UT)

UT works by sending sound waves through metal and interpreting the bounce-back. Seal welds, especially around steel backing, create false echoes or alternate sound paths, making interpretation difficult.

Problems with Steel Backing Left In Place

If the steel backing is not removed and is seal welded, it becomes nearly impossible to inspect the root of the weld via UT.

Suggested Solutions – Backing Width and Placement

One workaround is using wider backing so the seal weld can be placed away from the joint, or ensuring backing bars are removed post-weld.

Galvanizing and Venting Considerations

AGA Joint Classifications (Class 1, 2, 3)

The American Galvanizers Association categorizes joints to guide welders on what must be vented or sealed:

Class 1: Not sealed

Class 2: Partial seal

Class 3: Fully sealed and vented

Seal Welds for Preventing Zinc Entrapment

Seal welds help prevent molten zinc from entering overlaps and trapping air, which could expand during galvanizing and rupture the coating.

Overlapping Surface Area and Vent Hole Guidelines

If an overlapped joint exceeds 16 square inches, venting holes must be added—even if sealed—to allow zinc and air to escape safely.

Best Practices for Creating Seal Welds

Design Coordination – Getting Engineers Involved Early

Seal welds should be discussed at the design stage, not added casually in the field. Engineers must review load paths, inspection needs, and galvanizing plans.

Welder Technique and Attention to Detail

Use the same rigor as structural welds:

Proper preheat

Correct filler metals

Adherence to WPS (Welding Procedure Specification)

Adhering to Heat Input and Weld Size Requirements

Even tiny seal welds must meet minimum heat input standards to avoid shrinkage cracking and lack of fusion.

Resolving Code and Field Conflicts

Using Seal Welds Without Violating Flexibility Requirements

Where movement is expected, don’t weld the full perimeter—leave planned interruptions or use compliant flexible gaskets.

Engineering Solutions to Minimize Load Path Disruption

If welding near bolts, ensure the design isolates the seal weld from load-bearing elements or uses intermittent welds instead.

Balancing Cleanliness, Corrosion Control, and Strength

Finding the right balance means knowing when a seal weld is worth the risk—and ensuring it doesn’t introduce more problems than it solves.

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders