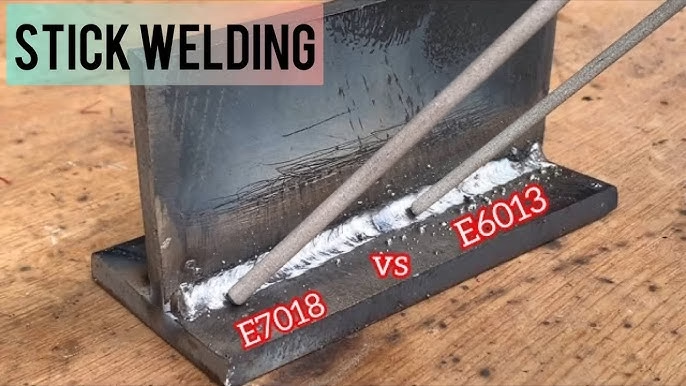

E6013 vs E7018 Stick Welding Electrodes: A Comprehensive Comparison

Stick welding, or Shielded Metal Arc Welding (SMAW), remains one of the most widely used welding processes in the world—valued for its simplicity, versatility, and cost-effectiveness. However, the choice of electrode can make or break the weld quality. Among the countless electrodes available, E6013 and E7018 are two of the most commonly used—and frequently confused—welding rods. This article dives deep into their characteristics, uses, and differences to help you make an informed decision for your next welding project.

Understanding Stick Welding Electrodes

Electrode Classification System (E6013 and E7018 Decoded)

Each electrode name isn’t just a number—it tells you a story. Let’s break them down:

E6013:

E = Electrode

60 = 60,000 psi tensile strength

1 = Usable in all positions

3 = Type of flux coating and current type (rutile-based, AC/DC)

E = Electrode

70 = 70,000 psi tensile strength

1 = All-position electrode

8 = Low-hydrogen, iron powder coating, suitable for AC or DC+

These classifications instantly give you clues about their strength, usability, and required technique.

Role of Flux Coating in Stick Electrodes

The flux covering each electrode type serves multiple purposes—it stabilizes the arc, shields the molten pool from atmospheric gases, and forms slag. For E6013, this flux is rutile-based, making it user-friendly and smooth. E7018, however, uses an iron powder, low-hydrogen coating, offering superior mechanical properties and minimal hydrogen inclusion—a key factor in structural applications.

E6013 Welding Electrode: Characteristics and Applications

Composition and Welding Behavior

E6013 electrodes feature a high titania (rutile) coating, which produces a very stable, soft arc and easy slag removal. The smooth arc makes it especially forgiving for less experienced welders and suitable for thin materials.

Ideal Welding Positions and Current Types

Thanks to its coating, E6013 supports all-position welding, making it versatile. It runs well on both AC and DC polarity, which is perfect for entry-level machines and repair work.

Typical Applications and Use Cases

E6013 shines in:

Sheet metal work

Light fabrication

Automotive repairs

Household DIY and farm equipment

Its arc isn’t deep-penetrating, so it’s perfect when you want a clean bead on a thinner surface without burn-through.

E7018 Welding Electrode: Characteristics and Applications

Composition and Welding Behavior

E7018 rods are low-hydrogen electrodes designed to deliver stronger welds with high ductility and impact strength. The iron powder in the coating increases deposition rates and reduces porosity, making them ideal for critical structural welds.

Low-Hydrogen Electrode Properties

E7018 must be kept in dry, moisture-free storage—typically in rod ovens or sealed containers. This is to preserve the low-hydrogen integrity, which is essential for preventing hydrogen-induced cracking, especially in high-strength steels.

Suitable Welding Positions and Current Types

E7018 also supports all-position welding, although vertical-up welds require more skill due to the heavier slag. It works best on DC+ (reverse polarity), but also runs on AC.

Common Use Cases in Industry

This rod is the go-to choice for:

Structural steel

Bridges

Pressure vessels

Pipe welding

Code work requiring AWS or ASME compliance

Head-to-Head Comparison: E6013 vs E7018

Mechanical Properties (Tensile Strength, Ductility)

E6013: 60,000 psi tensile strength; suitable for non-critical applications.

E7018: 70,000 psi tensile strength; higher ductility and toughness, especially in low-temperature environments.

Penetration Profile and Arc Characteristics

E6013: Shallow penetration, smooth arc, minimal spatter—great for thin materials.

E7018: Deeper penetration, crisp arc, slower travel—ideal for heavy-duty welding.

Ease of Use for Beginners and Professionals

E6013 is the friendliest rod for beginners, offering easy restarts and minimal rod sticking.

E7018 demands more skill, especially for vertical and overhead positions, but rewards with stronger welds.

Storage and Handling Considerations

E6013: No special storage needed.

E7018: Must be stored in an oven (typically 250°F–300°F) and kept dry to avoid hydrogen contamination.

Slag Type and Clean-Up Requirements

E6013: Fast-freezing, light slag that peels off easily.

E7018: Heavier slag, self-lifting in flat and horizontal welds but requires effort in vertical or overhead work.

Industry Suitability and Application Scenarios

Best Fit for Structural Welding

E7018 is unmatched here. With its superior mechanical properties and compliance with AWS and ASME codes, it’s essential for any project where weld integrity is critical.

Best Fit for Sheet Metal and Light Fabrication

E6013 is better suited for:

Fencing

Exhaust systems

Light frames

It doesn’t over-penetrate, making it safer for thin stock.

Welding Code Compliance and Standard Requirements

AWS D1.1 and ASME Section IX Considerations

E7018 is qualified under structural codes like AWS D1.1 and ASME Section IX for critical welds.

E6013 is not generally accepted for structural welds unless explicitly allowed.

Inspection, Acceptance, and Code Fit

E7018 welds pass radiographic and ultrasonic testing more reliably due to their reduced porosity and improved fusion.

Price and Availability in the Market

Cost per Pound/Kilogram Comparison

E6013 is typically cheaper and more accessible, making it attractive for general-purpose use.

E7018 costs more, but this is justified by the mechanical benefits and reliability it offers.

Availability for Hobbyists and Professionals

E6013 is widely available in most hardware stores and ideal for hobbyists.

E7018 is standard in professional and industrial supply shops.

Which Electrode Should You Use?

Key Factors to Consider (Material, Thickness, Conditions)

Choose E6013 if:

You’re working on thinner metals

You’re learning to weld or need a low-cost rod

Weld strength isn’t the top concern

Choose E7018 if:

You’re welding structural or critical components

You need higher tensile strength and impact resistance

Code compliance is necessary

Environment and Project Demands

For outdoor work with moisture-prone materials, E6013 may be safer due to fewer storage restrictions. But for any project where failure isn’t an option, E7018 is the trusted standard.

FAQs

Can I substitute E6013 with E7018 for structural work?

Not recommended. E7018 provides higher strength and is code-approved for structural work, while E6013 is not.

Why does E7018 require special storage?

Because it’s a low-hydrogen electrode, it must be kept dry to prevent moisture absorption that can cause hydrogen-induced cracking.

Is E6013 good for vertical welding?

Yes, it can be used in all positions, including vertical, though the arc is softer and may require technique adjustments.

What happens if I use E6013 on thick plates?

The shallow penetration may result in incomplete fusion or weak joints. Multiple passes might be necessary.

Do both electrodes run well on AC?

Yes, both E6013 and E7018 can be run on AC, but E7018 prefers DC+ for optimal performance.

Conclusion

While both E6013 and E7018 electrodes serve valuable roles in stick welding, they are designed for very different purposes. E6013 is user-friendly, cost-effective, and perfect for thin metal work. E7018, on the other hand, is a low-hydrogen powerhouse built for structural integrity and demanding environments. Whether you’re a weekend warrior or a certified welder on a jobsite, understanding when and how to use each rod will elevate the quality, safety, and success of your welds.

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders