Is FCAW Stronger Than MIG?

Introduction to Welding Strength Comparisons

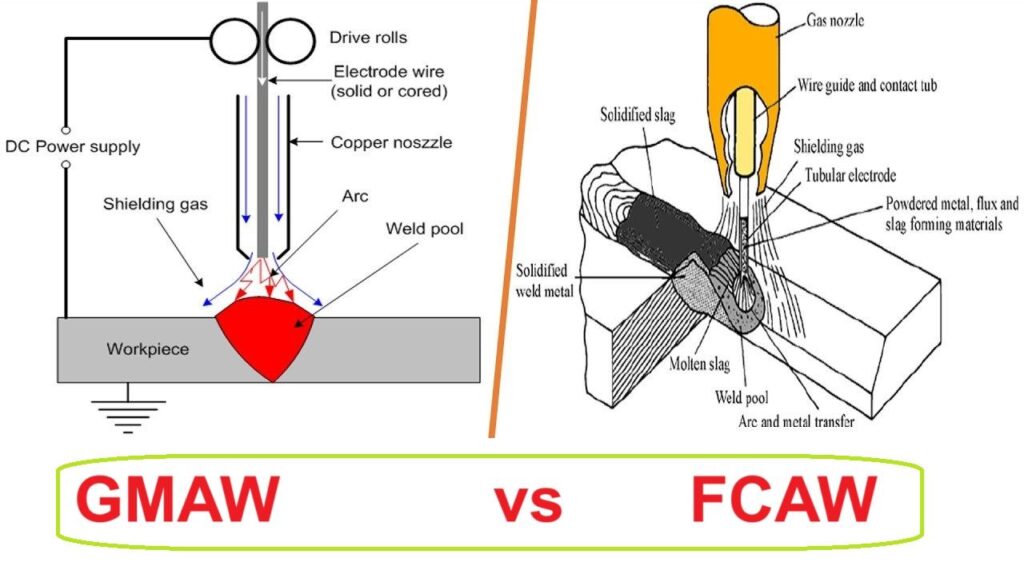

Welders often debate whether Flux-Cored Arc Welding (FCAW) is stronger than Gas Metal Arc Welding (GMAW), commonly known as MIG welding. The answer is not as straightforward as a yes or no. It depends on various factors like the materials being welded, the environment, the welder’s technique, and the specific type of wire or shielding used. But one thing’s for sure: when it comes to brute strength, Flux-Core often has the edge, especially in structural applications.

Why Strength Matters in Welding Applications

The mechanical strength of a weld determines whether a structure holds firm under pressure, resists fatigue, or fails catastrophically. In bridges, buildings, pipelines, and vehicles, the strength of each joint can be a matter of life and death. That’s why comparing processes like FCAW and MIG is more than just technical preference—it’s about performance, safety, and reliability.

Defining “Stronger” – Tensile Strength vs. Practical Strength

When we ask if one process is stronger than another, we’re usually referring to tensile strength—the maximum stress a weld can take before breaking. But real-world strength also involves penetration, fusion quality, ductility, and impact resistance. So we must weigh both lab-tested numbers and field performance.

What Is FCAW (Flux-Cored Arc Welding)?

Flux-Core is a semi-automatic or automatic arc welding process that uses a flux-filled tubular wire. It was designed to bring together the deep penetration of Stick welding (SMAW) with the speed of MIG.

Self-Shielded FCAW (FCAW-S)

FCAW-S doesn’t require external shielding gas because the flux core creates its own protective gas when burned. This makes it ideal for outdoor work in construction, pipelines, and field repairs where wind and weather are unpredictable.

Gas-Shielded FCAW (FCAW-G)

This variant of Flux-Core combines a flux core with external shielding gas (usually CO₂ or a mix with Argon). It provides cleaner welds with less spatter and is often used in shop environments for heavy-duty fabrication.

Differences in Shielding and Penetration

Flux-Core wires, especially those with rutile or basic fluxes, offer superior penetration compared to MIG. They also create a slag cover, which protects the weld as it cools and contributes to better mechanical properties in many cases.

Typical Strength Ranges of Flux-Core Welds

Welds made using Flux-Core electrodes like E71T-1 can have tensile strengths upwards of 70,000 psi, and with specialty wires, even up to 100,000 psi—surpassing most standard MIG applications.

What Is MIG Welding (GMAW)?

MIG welding uses a solid wire electrode fed through a gun and shielded by an external gas like Argon or CO₂. It’s prized for being clean, fast, and user-friendly, especially on thinner metals.

Solid Wire and Shielding Gas Usage

The wire used in MIG welding doesn’t contain flux, so it relies entirely on the shielding gas to protect the molten weld pool from atmospheric contamination. This makes it less suitable for windy outdoor settings unless properly shielded.

Advantages in Thin Metals and Clean Environments

MIG welding excels in fabrication shops and automotive work because it produces minimal slag, offers excellent bead appearance, and allows for high-speed production. However, it doesn’t penetrate as deeply as FCAW in most cases.

Strength Characteristics of MIG Welds

Typical MIG wire like ER70S-6 also offers around 70,000 psi tensile strength, but the real-world fusion and penetration can be less reliable on thicker or dirty materials without edge preparation or multiple passes.

Comparing FCAW and MIG in Terms of Strength

Tensile Strength Values of Common Electrodes

| Process | Electrode | Tensile Strength (psi) |

|---|---|---|

| FCAW | E71T-1 | 70,000–90,000 |

| MIG | ER70S-6 | ~70,000 |

Weld Penetration and Fusion

Penetration depth is critical in thicker metals. FCAW, particularly in the FCAW-G variant, tends to melt deeper into the base metal, producing stronger mechanical interlocking. MIG welds can lack this unless done with precise control or multiple passes.

Impact Toughness and Crack Resistance

FCAW electrodes, especially low-hydrogen types, exhibit better impact resistance, especially at low temperatures. This makes them ideal for bridges, skyscrapers, and offshore structures. MIG, while strong, is more brittle under these extreme conditions.

Factors Influencing on Weld Strength

Welding Technique and Parameters

Even the strongest wire won’t help if the travel speed, voltage, or stick-out are off. FCAW tends to be more forgiving in terms of technique compared to MIG, which needs tighter control.

Material Type and Thickness

For 1/4 inch and thicker steel, FCAW is more robust and efficient. MIG shines on thin sheet metal, but lacks the brute strength for single-pass structural welds unless extensively prepped.

Environmental Conditions During Welding

FCAW-S thrives in wind, rain, and snow due to its self-shielding properties. MIG requires a clean, still-air environment—otherwise, porosity or weak welds are likely.

Filler Metal and Shielding Gas Selection

The filler material’s composition and the gas mix can impact the final strength. MIG with 75/25 (Argon/CO₂) produces smoother arcs but may compromise penetration compared to straight CO₂ used in FCAW-G.

Structural Applications and Code Requirements

FCAW in Heavy Structural Steel

FCAW is the go-to process in bridge building, shipyards, and high-rises, where code requirements (AWS D1.1, ASME) demand tested, high-strength welds.

MIG in Automotive and Light Fabrication

MIG is dominant in car panels, appliance frames, and thin-gauge sheet metal work. It’s clean, fast, and sufficient—but usually not strong enough for heavy loads without reinforcement.

Pros and Cons of FCAW vs. MIG Regarding Strength

FCAW Strength, Advantages, and Limitations

Pros:

Higher penetration and better fusion

Works in dirty or windy environments

Strong slag protection and crack resistance

Cons:

More spatter and slag to clean

Heavier equipment in some cases

MIG Strength, Advantages, and Limitations

Pros:

Clean, smooth welds

Fast for thin metals

Easy to learn and control

Cons:

Poor outdoor performance

Lower penetration on thicker materials

Misconceptions About Welding Strength

Visual Appearance vs. Structural Integrity

A smooth MIG bead might look nicer, but it doesn’t always mean it’s stronger. Some of the strongest welds (like FCAW) look rougher due to slag coverage but offer superior toughness.

Strength Is Not Just About the Welding Process

Technique, setup, joint prep, and weld design matter more than just picking FCAW or MIG. But in side-by-side tests, FCAW usually outperforms MIG in structural integrity.

FAQs

Is FCAW better for thicker materials than MIG?

Yes, FCAW provides deeper penetration and stronger welds in thick steel, especially in single-pass applications.

Can MIG welds be as strong as FCAW?

They can be, with proper preparation and multiple passes, but FCAW still typically outperforms MIG in structural strength.

Which process is more suitable for out-of-position welding?

FCAW, especially E71T-1 or E71T-8 wires, is designed for out-of-position welding with excellent control and strength.

Does shielding gas affect weld strength significantly?

Absolutely. The choice of gas can influence penetration, arc stability, and overall mechanical properties of the weld.

Which welding method is better for beginners aiming for strong welds?

FCAW-S is often more forgiving and produces strong welds with less precision, making it a good choice for beginners focused on strength.

Conclusion: Is FCAW Stronger Than MIG?

In most structural and heavy-duty scenarios, yes—FCAW is stronger than MIG. It offers better penetration, higher tensile strength potential, and superior impact resistance. That said, MIG has its strengths in speed, cleanliness, and light fabrication work. Choosing between the two depends on the application, material, and desired performance characteristics. But if strength is your #1 priority—especially for critical joints—FCAW usually takes the lead.

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders