Carbon Steel Welding Electrodes – A Complete Guide

When it comes to welding carbon steel, the choice of electrode can make the difference between a flawless weld and one riddled with defects. Carbon steel is the most widely used steel type in manufacturing, construction, and repair because of its strength, availability, and cost-effectiveness. However, welding it requires precise electrode selection to ensure strong, durable, and defect-free joints.

What Are Welding Electrodes?

A welding electrode is essentially the filler material that melts and fuses with the base metal during welding. In Shielded Metal Arc Welding (SMAW), electrodes are coated with flux, which protects the molten weld pool from atmospheric contamination and improves weld quality. Electrodes are classified based on their mechanical properties, welding positions, and coating types.

Why Carbon Steel Requires Special Electrode Selection

Carbon steel comes in various grades—low, medium, and high carbon—each with different hardness, ductility, and weldability. An unsuitable electrode can cause cracking, poor penetration, or low joint strength. Choosing the right electrode ensures proper fusion, mechanical strength, and resistance to environmental damage.

Classification of Carbon Steel Welding Electrodes

AWS/ASME Electrode Numbering System Explained

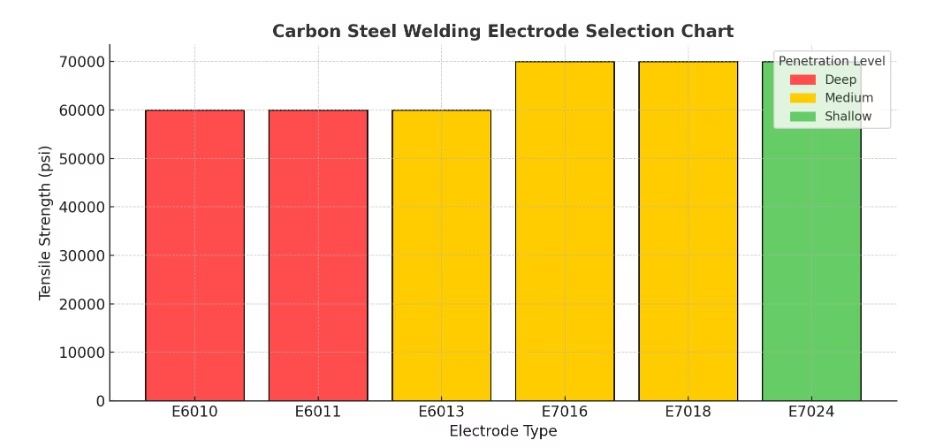

The American Welding Society (AWS) and the American Society of Mechanical Engineers (ASME) have a standardized system to classify electrodes. For example, E6010 means:

E – Electrode

60 – Minimum tensile strength of 60,000 psi

1 – Suitable for all positions (flat, horizontal, vertical, overhead)

0 – Coating type and current characteristics

This numbering system applies to all carbon steel SMAW electrodes, helping welders select the right rod for the job.

Key Factors in Electrode Classification

Electrode codes reveal critical information, including:

Tensile Strength – Determines how much load the weld can handle before breaking.

Welding Position – Some rods are all-position, while others are limited to flat and horizontal.

Flux Coating Type – Influences penetration, arc stability, and slag formation.

Current Type – Specifies whether the electrode can be used with AC, DC+, or DC–.

Types of Electrodes for Carbon Steel

Mild Steel Electrodes

E6010 rods are known for their strong penetrating arc, making them ideal for welding through rust, paint, or contaminants. They are commonly used in pipeline work and require DC+ polarity.

E6011

E6011 offers similar deep penetration as E6010 but can run on both AC and DC, making it versatile for field repairs where power sources vary.

E6013 electrodes produce smooth, clean welds with minimal spatter, suitable for thin materials and general-purpose fabrication. They excel in situations where appearance is important.

Low Hydrogen Electrodes

E7018 rods are the go-to choice for structural steel welding, offering high strength and reduced risk of hydrogen-induced cracking. They produce smooth welds with excellent impact resistance.

E7016

E7016 electrodes also provide low hydrogen deposits but have slightly different slag and arc behaviors, often preferred in certain code work.

High Tensile Strength Electrodes

E7024

E7024 is designed for high-speed welding in flat and horizontal positions, delivering a large amount of filler metal quickly.

Shielding Methods and Coating Types

Cellulosic Coated Electrodes

These electrodes have a coating high in cellulose content, producing a forceful, penetrating arc and a fast-freezing slag. Ideal for vertical down welding.

Rutile Coated Electrodes

Rutile-based coatings provide a smooth arc, easy slag removal, and aesthetically pleasing weld beads. They are user-friendly, especially for beginners.

Basic/Low Hydrogen Coated Electrodes

These coatings minimize hydrogen content in the weld, preventing cracking in high-strength steels. They require proper storage to maintain performance.

Electrode Selection Criteria for Carbon Steel Welding

Base Metal Thickness and Strength

Thin metals require electrodes with lower penetration (e.g., E6013), while thick plates need deeper penetration rods like E6010 or E7018.

Welding Position

If welding in all positions, choose a rod with a “1” in the third digit (E6010, E7018). Flat-only work can use “2” rods like E7024.

Current Type (AC or DC)

Some electrodes are polarity-specific, so match your rod to your power source.

Environmental Conditions (Moisture, Wind)

For outdoor work, electrodes with fast-freezing slag (E6010, E6011) resist slag running in windy conditions.

Storage and Handling

Importance of Dry Storage for Low Hydrogen Rods

E7018 and similar rods must be kept dry to avoid moisture absorption, which can cause hydrogen-induced cracking.

Re-baking Procedures

If low hydrogen rods get damp, they can be re-baked at specific temperatures (often 250–300°C) in an electrode oven.

Applications of Carbon Steel Electrodes

Structural Steel Fabrication

E7018 rods are the standard for buildings, bridges, and heavy frameworks.

Pipeline Welding

E6010 and E6011 excel in pipeline root passes due to deep penetration.

Shipbuilding and Heavy Equipment

A mix of E6013 and E7018 is used for repairs and fabrications in the marine and heavy machinery sectors.

Welding Defects

Porosity

Caused by contamination or excessive moisture in electrodes.

Slag Inclusions

Happen when slag is not properly removed between passes.

Cracking from Moisture Contamination

Particularly, an issue arises with low-hydrogen rods exposed to humidity.

Best Practices

Maintaining Correct Arc Length

Too long an arc can cause spatter and undercut; too short can lead to sticking.

Preheating and Post-Weld Heat Treatment Considerations

Higher carbon steels may require preheating to reduce cracking risks.

Avoiding Overheating and Burn-Through

Control amperage and travel speed to prevent thinning of the base metal.

FAQs

Can I use E6013 for thick carbon steel?

E6013 can weld thicker steel, but it is better suited for thin to medium sections. For heavy plates, deep-penetrating electrodes like E7018 or E6010 are preferred.

Why do E7018 rods need to be kept dry?

Moisture in low hydrogen electrodes can cause hydrogen-induced cracking, compromising weld integrity.

What’s the difference between E6010 and E6011?

E6010 requires DC+, while E6011 can run on both AC and DC, making it more versatile in power-limited conditions.

Which electrode is best for structural steel?

E7018 is the industry standard for structural applications due to its high strength and low hydrogen properties.

Can I weld carbon steel outdoors in windy conditions?

Yes, but choose fast-freezing slag electrodes like E6010 or E6011, as they handle wind better than rutile or basic-coated rods.

Conclusion

Choosing the correct welding electrode for carbon steel is not just about following a chart—it’s about understanding the base metal, welding position, working environment, and desired mechanical properties. From deep-penetrating E6010 to smooth-finishing E7018, every electrode has a purpose. By knowing their strengths, limitations, and best practices, welders can ensure strong, reliable, and professional-grade welds every time.

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders