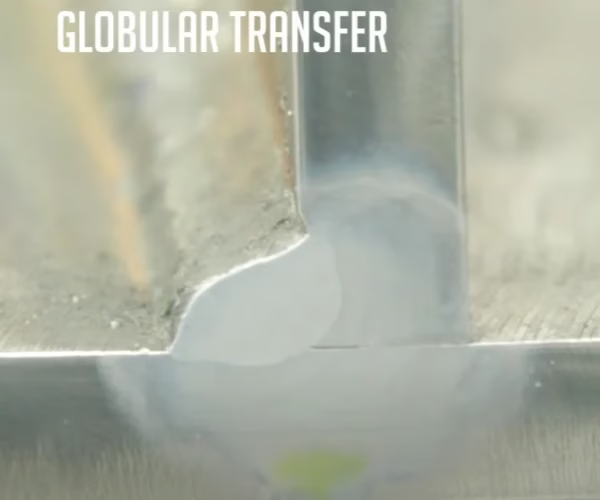

Globular Transfer in MIG Welding

Globular transfer is one of the classic metal-transfer modes encountered in Gas Metal Arc Welding (GMAW), commonly called MIG (Metal Inert Gas) welding when inert gases are used. It sits between short-circuiting transfer and spray transfer in both behavior and effects: the molten wire forms relatively large, irregular droplets that detach under gravity and electromagnetic forces and fall across the arc to the workpiece. Globular transfer is familiar to fabricators because it is simple to obtain (often the default with CO₂ or CO₂-rich gases) but also because it produces a lot of spatter and an unpredictable bead profile. This article explains the physics, the controlling variables, the pros and cons, and practical guidance for welding instructors, shop supervisors, and practicing welders who want to understand when globular transfer is useful — and how to control or avoid it.

What is Globular Transfer?

Physical mechanics of globular transfer

In globular transfer the molten metal from the consumable electrode forms large, roughly spherical or ellipsoidal droplets. The droplet grows at the end of the wire until forces (gravity, arc pressure, pinch from the magnetic field and surface tension imbalances) allow it to detach and traverse the arc gap to the weld pool. Unlike short-circuit transfer — where the wire physically touches the work and creates a rapid short — and unlike spray transfer — where tiny droplets are driven across the arc in a smooth, high-frequency stream — globular transfer is irregular and discontinuous. Multiple droplets may drip, sometimes merging in mid-air, causing large and unpredictable impact events on the puddle.

Droplet formation, size and detachment behavior

The droplets in globular transfer are typically larger than the electrode diameter and vary in size. That size and irregularity are the root cause of several characteristic results: heavy spatter when droplets break up on impact, inconsistent bead contour, and occasional lack of fusion or undercut when a large droplet displaces shielding gas or disturbs the puddle. Think of globular transfer like tossing handfuls of marbles across a stream: sometimes they land cleanly; other times they hit and bounce or scatter—unpredictable.

Key factors that control Globular transfer

Globular transfer is not a mysterious “mode” that appears by magic — it is the product of several interacting variables. Change one or more of these and you steer the process toward short-circuiting, spray, or pulsed modes.

Welding current and voltage relationship

Current controls how fast the electrode melts and the energy delivered through the arc. At low currents you get short circuits; at much higher currents (with suitable gas) you can reach spray transfer. Globular typically appears in the mid-range where the wire melts fast enough to form large droplets, but the arc conditions are not supportive of fine, atomized spray. Voltage also affects the arc length and droplet detachment behavior: higher voltage tends to lengthen the arc and can encourage smaller, more frequent detachment, while lower voltage shortens the arc and can favor larger droplets.

Wire diameter and wire-feed speed

A thicker wire will naturally form larger droplets at the same melting rate compared with a thinner wire. Wire-feed speed sets how much metal is supplied; high feed speeds at a fixed current increase deposition and favor larger droplets unless you increase current proportionally. Managing the ratio of feed speed to current is essential to keep droplet formation in the behavior you want.

Shielding gas composition and its role

Shielding gas is one of the most decisive factors. CO₂ or CO₂-rich mixes promote a hotter, more forceful arc but do not atomize droplets as cleanly as argon-rich mixes. Argon promotes spray transfer more readily; CO₂ tends to produce globular (or even more irregular transfer) unless you alter current or use pulsing. The gas choice therefore often determines whether globular transfer is likely at a given setting.

Contact-tip-to-work distance (stick-out) and tip condition

Longer stick-out increases resistance heating of the wire and can change the melting characteristics, often encouraging irregular droplet formation. Worn contact tips, poor contact between wire and tip, or inconsistent stick-out all increase instability and encourage globular behavior. Maintaining tip condition and controlling stick-out are low-cost fixes for erratic transfer.

How globular transfer different

Understanding globular transfer requires comparing it to the Other Transfer Modes

Short-circuit (short-arc) transfer

Short-circuit transfer is a low-heat mode where the electrode actually touches the puddle at frequent intervals, creating short circuits that melt the wire in small increments. It produces small droplets, low heat input, and is good for thin materials and positional welding. Globular transfer is higher heat, larger droplets, and is less position-friendly. The transition from short to globular often happens when current or wire feed increases beyond the short-circuit stable range.

Spray transfer

Spray transfer gives many tiny droplets that are “sprayed” across the arc in a smooth stream — low spatter, stable arc, good bead appearance, and deep penetration. Spray requires higher current and a gas that supports atomization (argon-rich). Globular sits between short and spray: it has larger droplets and higher spatter than spray, and it does not provide the smooth deposition characteristics that welders like for cosmetic or critical work.

Pulsed-spray transfer

Pulsed MIG artificially modulates current between high and low levels to force small droplet detachment even at lower average heat input. It gives the advantages of spray transfer but with lower mean heat — ideal for materials and positions that would otherwise be forced into globular or short modes. If consistency and low spatter are required but you cannot reach continuous spray conditions, pulsed MIG is a common engineering solution.

Advantages and disadvantages of globular transfer

Practical advantages

Globular transfer offers some practical benefits that explain its continued use:

Simplicity and cost: It is easy to obtain using common CO₂ or CO₂-rich mixtures and conventional power sources — no pulsed equipment required.

High deposition rate: For a given setup, globular mode can deposit metal rapidly because droplets are large.

Deep penetration potential: When well-controlled, globular transfer can give adequate penetration for many structural joints.

Drawbacks

However, the disadvantages are significant:

Heavy spatter: Large irregular droplets create significant spatter, increasing cleanup and post-weld grinding time.

Arc instability and unpredictability: The irregular droplet transfer causes inconsistent bead shape, possible undercut, and variable mechanical performance unless closely managed.

Poor positional performance: Because droplets fall rather than stream, overhead or vertical welding is more challenging.

More fumes and potential porosity risk: Disturbance to shielding gas can permit porosity formation especially with long arcs or drafts.

Typical applications and when to Globular transfer

Industries and joint types where globular is common

Globular transfer tends to be used in heavy fabrication, structural steel, shipbuilding, and other industries where:

Cost-effectiveness (using CO₂ rather than high-argon blends) is a priority.

Cosmetic surface finish is not critical.

Equipment is conventional (no pulsed MIG) and the shop values simplicity.

Large cross-section joints where positional welding is not required.

Situations where globular transfer should be avoided

Avoid globular transfer when:

Weld appearance and low spatter are important (automotive, architectural).

Welding thin gauge sheet or delicate assemblies requiring low heat input is needed.

Positional welding (vertical/uphill, overhead) is necessary.

Fume and smoke control is a priority and minimal spatter is desired.

Troubleshooting — common problems and fixes

Reducing spatter and improving bead shape

If you are stuck with globular transfer but need to reduce spatter:

Increase argon content in shielding gas (if possible) to move toward spray.

Reduce wire diameter or reduce wire-feed speed (or reduce feed relative to current) to decrease droplet size.

Clean the base metal and wire to avoid contamination that destabilizes transfer.

Shorten stick-out and ensure solid contact tip/wire engagement.

Consider switching to pulsed MIG or a higher horsepower machine if you need spray characteristics.

Moving from globular to spray or pulsed transfer

Gas change: Move to a more argon-rich mix.

Increase current/voltage: but do so within the equipment and material limits — spray thresholds vary with wire and gas.

Reduce wire diameter: thinner wire atomizes more readily.

Consider pulsed MIG: if the machine supports pulsing, you can achieve spray-like small droplet transfer at lower average heat.

Make changes one variable at a time and document results — that is the only reliable way to find the threshold for your specific machine, wire, and gas.

Metallurgical and weld-quality considerations

Heat input, HAZ width, mechanical properties and post-weld requirements

Globular transfer tends to deliver higher local heat input than short-circuiting modes because droplets are large and the arc is generally hotter than in short circuits. Higher heat input increases HAZ width, changes cooling rates, and can influence microstructure — potentially leading to coarser grains or softened zones depending on the alloy. For carbon steels used in structural applications this often isn’t a show-stopper, but for heat-treatable alloys or thin sections the increased heat input can compromise properties, increase distortion, and require post-weld heat treatment or repair work.

Safety, fume and environmental considerations

Because globular transfer produces more spatter and frequently uses CO₂ or CO₂-rich gas, fume generation can be higher, and spatter increases fire risk and cleanup time. Ensure:

Adequate local exhaust ventilation (LEV) and respiratory protection where fume exposure is significant.

Proper PPE (eye/face protection, flame-resistant clothing) because spatter is abundant.

Clean work area to reduce risk of igniting debris with hot spatter.

FAQs

Is globular transfer acceptable for structural welding?

Yes — globular transfer is commonly used in structural steel fabrication where cost and deposition rate are prioritized and cosmetic finish is not critical. However, you must control spatter, ensure fusion, and account for higher heat input and possible distortion. Documented welding procedures and post-weld inspection should confirm mechanical performance.

How do I reduce spatter when I’m getting globular transfer?

The most effective actions are increasing the argon fraction of the shielding gas, reducing wire diameter or wire-feed speed relative to current, shortening stick-out, and ensuring clean wire and tip condition. If possible, switch to pulsed MIG or adjust parameters to reach spray transfer.

Can gas choice alone change globular transfer to spray transfer?

Often yes — switching from 100% CO₂ to an argon-rich mix will move the process toward spray transfer at the same current/voltage. However, the exact threshold depends on wire diameter, machine capability, and current; be prepared to adjust power settings as well.

Is globular transfer safe for positional welding (vertical/uphill or overhead)?

Generally no. Globular transfer’s large, gravity-driven droplets make positional welding difficult and produce poor bead formation and excessive spatter. Short-circuit or pulsed/spray transfer modes are preferred for positional work.

When should I train students to avoid globular transfer?

Teach globular transfer as part of the process spectrum so students understand the physics and how to recognize it. Emphasize avoidance when welding thin materials, doing positional welds, or where finish and minimal post-work are required. Provide hands-on exercises where students deliberately transition from globular to spray and pulsed modes to see the differences in bead quality and spatter.

Conclusion

Globular transfer is a workhorse behavior in MIG welding: easy to obtain, high deposition, and cost-effective when using CO₂ or CO₂-rich gases and conventional equipment. But its irregular droplets and high spatter reduce weld quality, increase cleanup, and limit positional performance. Understanding the variables that produce globular transfer — current, voltage, wire size, gas composition, and operator technique — gives welders the power to either exploit it where suitable (heavy fabrication, non-critical joints) or convert to smoother transfer modes when quality and appearance matter (through gas changes, wire adjustments, or pulsed equipment). For instructors and shop leads, teaching the system approach (change one variable at a time, measure outcomes, document thresholds) is the most reliable path to consistent, predictable welding.

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders