Spray vs Short-Circuit vs Pulsed MIG

What Are MIG Transfer Modes?

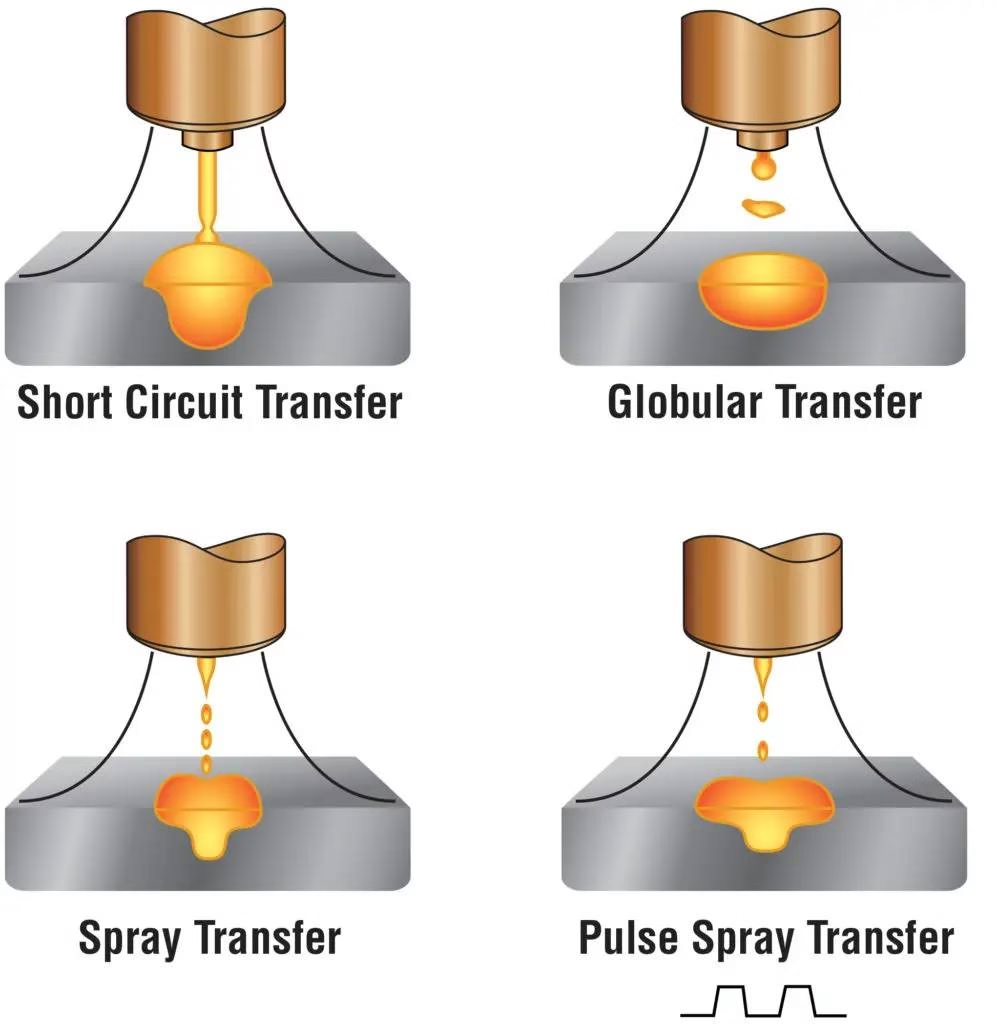

MIG transfer modes describe how molten filler metal moves from the wire electrode into the weld pool during MIG (GMAW) welding. The selected transfer mode directly affects:

- Heat input

- Penetration

- Spatter

- Bead appearance

- Welding position capability

The three main MIG transfer modes are:

- Short-Circuit Transfer

- Spray Transfer

- Pulsed Spray Transfer

Why MIG Transfer Modes Matter

Choosing the correct transfer mode helps welders:

- Avoid burn-through on thin material

- Achieve proper fusion on thick joints

- Reduce spatter and cleanup time

- Improve weld quality and consistency

Short-Circuit Transfer (Short Arc MIG)

How It Works

- The wire touches the weld pool, causing a short circuit

- Current rises, melting the droplet

- The arc reignites

- Cycle repeats many times per second

Typical Settings

- Voltage: 16–21 V

- Current: 50–200 A

- Wire size: 0.023″–0.035″

- Shielding gas: 100% CO₂ or 75/25 Argon/CO₂

Advantages

- Low heat input

- Works in all positions

- Good control on thin material

- Ideal for beginners

Limitations

- High spatter

- Shallow penetration

- Risk of cold lap on thick steel

Best Uses

- Thin sheet metal

- Automotive work

- Vertical and overhead welding

- Repair and field welding

Spray Transfer MIG

How It Works

- Molten metal transfers as fine droplets across a continuous arc

- Wire never touches the weld pool

- Occurs only above the transition current

Typical Settings

- Voltage: 24–32 V

- Current: 220–400+ A

- Shielding gas: 90%+ Argon (Argon-rich mix required)

Advantages

- Deep penetration

- Very smooth bead

- Minimal spatter

- High deposition rate

Limitations

- Very high heat input

- Not suitable for thin metal

- Limited to flat and horizontal positions

Best Uses

- Thick plate welding

- Structural steel

- Shop welding in flat position

Pulsed MIG Transfer

How It Works

- Current alternates between:

- Peak current (detaches one droplet)

- Background current (maintains arc)

- One pulse = one droplet

Key Feature

Spray-like transfer with lower overall heat input

Advantages

- Excellent arc control

- Low spatter

- Lower heat than spray transfer

- Works in all positions

Limitations

- Requires advanced inverter machine

- Higher equipment cost

- More complex setup

Best Uses

- Stainless steel

- Aluminum

- Pipe welding

- All-position structural welding

Quick Comparison Table

| Feature | Short-Circuit | Spray | Pulsed MIG |

|---|---|---|---|

| Heat Input | Low | High | Medium |

| Spatter | High | Very Low | Very Low |

| Penetration | Shallow | Deep | Controlled |

| Positions | All | Flat/Horizontal | All |

| Skill Level | Beginner | Intermediate | Advanced |

Shielding Gas Summary

- 100% CO₂ → Short-circuit only

- 75/25 Ar/CO₂ → Short-circuit, some pulsed

- 90%+ Argon → Spray and pulsed MIG

Common Mistakes

- Using spray transfer on thin metal

- Wrong shielding gas selection

- Confusing pulsed MIG with spray transfer

- Assuming one transfer mode fits all jobs

FAQs

Can spray transfer be used with 100% CO₂?

No. Spray transfer requires argon-rich shielding gas.

Is pulsed MIG the same as spray transfer?

No. Pulsed MIG is a controlled form of spray transfer with lower average heat input.

Which MIG transfer mode has the least spatter?

Spray and pulsed MIG produce the least spatter.

What is the safest MIG transfer mode for beginners?

Short-circuit transfer due to lower heat and better control.

Can one machine perform all MIG transfer modes?

Only advanced inverter machines support pulsed MIG; basic machines support short-circuit and sometimes spray.

Conclusion

Understanding MIG transfer modes transforms MIG welding from a trial-and-error process into a controlled, predictable operation. Short-circuit offers control, spray delivers power, and pulsed MIG provides balance. When welders match the transfer mode to the application, weld quality, efficiency, and consistency improve dramatically.

Key Takeaway

There is no single best MIG transfer mode. The best choice depends on:

- Material thickness

- Welding position

- Joint design

- Available equipment

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders