Backstep Welding Technique

Introduction

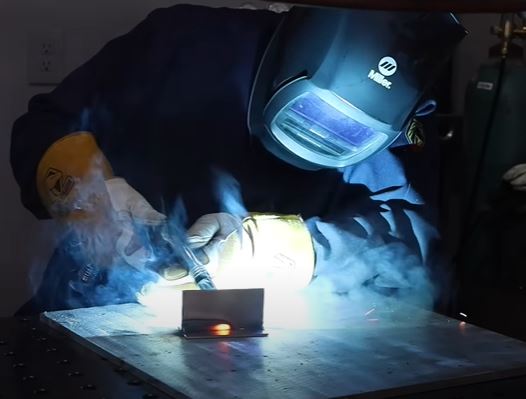

Backstep welding is a specialized welding technique that holds significant importance in the welding industry due to its ability to minimize distortion and improve weld quality. Whether you’re a seasoned welder or just starting, understanding the intricacies of backstep welding can greatly enhance your skills and the quality of your work.

What is Backstep Welding?

Backstep welding is a technique where the welder moves in a series of small, sequential steps in the opposite direction of the overall weld progression. Unlike traditional welding methods where you typically weld continuously in one direction, backstep welding involves starting at the end of the weld joint and moving backwards in short segments. This method helps in distributing heat more evenly and reduces the chances of warping or distortion.

Benefits of Backstep Welding

The backstep welding technique offers several key benefits that make it a preferred choice for many welding projects:

- Reduction of Distortion: One of the most significant advantages of backstep welding is its ability to minimize distortion in the workpiece. By welding in short, controlled segments and moving in the opposite direction, the heat input is more evenly distributed, reducing the risk of warping.

- Improved Control Over Weld Quality: Backstep welding allows for greater control over the welding process, leading to higher quality welds. The technique helps in achieving a more consistent bead and reduces the likelihood of defects.

- Enhanced Mechanical Properties: The backstep welding technique can result in stronger welds with improved mechanical properties. The controlled heat input and reduced distortion contribute to a more robust and reliable weld.

Step-by-Step Guide to Backstep Welding

Mastering backstep welding requires understanding each step of the process and applying best practices. Here’s a detailed guide to help you get started:

Preparing the Workpiece:

- Clean the workpiece thoroughly to remove any contaminants.

- Ensure the edges to be welded are properly aligned and clamped securely.

Setting Up the Welding Equipment:

- Select the appropriate welding machine and settings based on the material and thickness of the workpiece.

- Use the correct electrode or filler wire for the job.

Performing the Backstep Welding Process:

- Begin welding at the end of the joint, making a short weld segment.

- Move backwards to the next segment, overlapping slightly with the previous one.

- Continue this process until the entire joint is welded, ensuring each segment is consistent in size and quality.

Types of Backstep Welding Techniques

There are various approaches to backstep welding, each suited to different applications and skill levels:

- Manual Backstep Welding: This involves the welder manually controlling the welding torch and making the backstep movements. It requires a high level of skill and precision.

- Semi-Automatic Backstep Welding: In this method, a mechanized system assists the welder in making the backstep movements, providing greater consistency and reducing fatigue.

- Automated Backstep Welding: Fully automated systems perform the backstep welding process without human intervention, ensuring the highest level of precision and repeatability.

Applications of Backstep Welding

Backstep welding is used across various industries due to its versatility and effectiveness:

- Industries Using Backstep Welding: This technique is commonly used in industries such as aerospace, automotive, shipbuilding, and construction where precision and structural integrity are paramount.

- Common Projects and Components: Backstep welding is ideal for welding large, flat plates, thin-walled structures, and components that are prone to distortion.

Challenges and Limitations of Backstep Welding

While backstep welding offers many advantages, it also presents certain challenges:

- Potential Issues: Common issues include maintaining consistent weld quality across segments and ensuring proper overlap between steps. Careful attention to technique and practice can mitigate these problems.

- Limitations Compared to Other Techniques: Backstep welding may not be suitable for all types of joints and materials. It can also be more time-consuming than continuous welding methods.

Tips for Successful Backstep Welding

To achieve the best results with backstep welding, consider these tips:

- Best Practices: Maintain a steady hand and consistent speed when making weld segments. Ensure each segment is of uniform length and properly overlapped with the previous one.

- Common Mistakes to Avoid: Avoid excessive heat input, which can lead to warping and defects. Practice proper technique to ensure each weld segment is properly aligned and consistent.

FAQs

What is the main advantage of backstep welding?

The main advantage of backstep welding is its ability to minimize distortion in the workpiece by evenly distributing heat input.

Can backstep welding be used on all metals?

While backstep welding can be used on a variety of metals, it is particularly effective on materials prone to distortion, such as thin-walled structures and large plates.

How does backstep welding affect weld quality?

Backstep welding improves weld quality by providing greater control over the welding process, resulting in more consistent and defect-free welds.

Is backstep welding suitable for beginners?

Backstep welding requires a certain level of skill and precision, making it more suitable for experienced welders. However, with practice, beginners can also learn to master the technique.

What equipment is necessary for backstep welding?

Essential equipment includes a suitable welding machine, the correct electrode or filler wire, and tools for cleaning and preparing the workpiece.

Conclusion

Backstep welding is a valuable technique that can significantly enhance the quality and integrity of your welds. By understanding its benefits, applications, and the proper way to execute it, you can tackle challenging projects with greater confidence and success. Whether you’re welding thin-walled structures or large plates, backstep welding offers a reliable method to achieve high-quality results with minimal distortion.

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders