P Number, F Number, and A Number in Welding (ASME Section IX) In pressure vessel and piping fabrication, ASME Section IX stands as a cornerstone for regulating welding qualifications. Among the most essential classifications within this code are the P Number, F Number, and A Number. These numerical designations simplify …

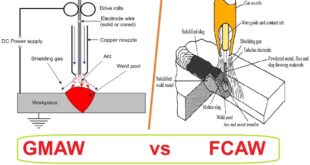

Read More »Is FCAW Stronger Than MIG?

Is FCAW Stronger Than MIG? Introduction to Welding Strength Comparisons Welders often debate whether Flux-Cored Arc Welding (FCAW) is stronger than Gas Metal Arc Welding (GMAW), commonly known as MIG welding. The answer is not as straightforward as a yes or no. It depends on various factors like the materials …

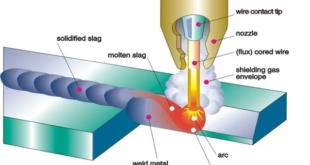

Read More »FCAW Gas-Shielded vs Self-Shielded

Flux-Cored Arc Welding: Self-Shielded vs Gas-Shielded Welding is at the core of modern metal fabrication, making it possible to construct bridges, ships, skyscrapers, and pipelines. Among the numerous welding methods available today, Flux-Cored Arc Welding (FCAW) has carved a niche for itself, especially in heavy industrial sectors. This semi-automatic or …

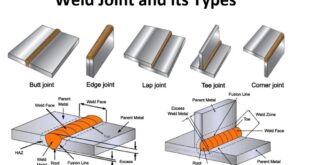

Read More »Designing Welded Joints

Designing Welded Joints: Types, Symbols, and Best Practices Welding is the backbone of modern metal fabrication, enabling the creation of strong, permanent joints in everything from pipelines to skyscrapers. However, the strength and integrity of a welded assembly aren’t just determined by the welder’s skill—it begins with smart joint design. …

Read More »ASME Section IX Quiz

ASME Section IX Quiz Welcome to our ASME Section IX sample quiz — your go-to resource for brushing up on welding and brazing qualification standards. Whether you’re an industry professional aiming to deepen your expertise, a student gearing up for certification exams, or simply curious about your welding knowledge, these …

Read More »6010 vs 7018

Does Electrode Choice Matter? 6010 vs 7018 When performing Shielded Metal Arc Welding (SMAW) — more commonly known as stick welding — selecting the right electrode isn’t just a matter of preference; it’s a critical factor that can make or break your weld. Among the vast variety of electrodes available, …

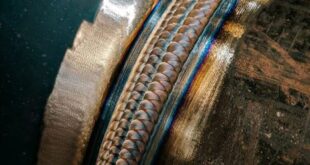

Read More »Weld Bead Size and Deposition Rate

Weld Bead Size and Deposition Rate Welding might look like sparks and smoke to the untrained eye, but behind every strong weld lies a balance of science, skill, and control. Two key factors—weld bead size and deposition rate—play an outsized role in determining not only the appearance of a weld …

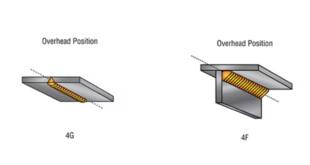

Read More »Overhead Position

Overhead Position Welding: Techniques, Challenges, and Best Practices What Is Overhead Position Welding? Overhead position welding is a challenging welding technique where the workpiece is located above the welder, and the weld is performed from the underside of the joint. Unlike flat or horizontal welding, the molten metal must be …

Read More »Seal Weld

What Is a Seal Weld? What Is a Seal Weld? A seal weld is a type of weld applied primarily to prevent the passage of fluids, gases, or contaminants—not to provide structural strength. Unlike load-bearing welds, its role is sealing gaps or joints to prevent leaks, improve corrosion resistance, and …

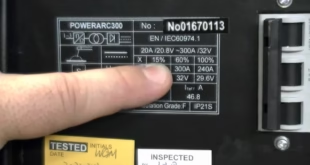

Read More »Duty Cycle

What Is Duty Cycle in Welding? In welding operations, one technical specification that plays a crucial role in equipment performance is the duty cycle. Despite its importance, this parameter is often misunderstood or overlooked, leading to improper equipment use and reduced productivity. Why Duty Cycle Matters in Welding The duty …

Read More » Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders