E7024 Welding Electrode: Complete Technical Guide The E7024 welding electrode is a high-deposition, iron-powder, low-hydrogen-type electrode widely used in Shielded Metal Arc Welding (SMAW) for flat and horizontal fillet welds. It is designed for productivity rather than positional versatility, making it a preferred choice in fabrication environments where speed, smooth …

Read More »HAZ in Aluminum Welds

Understanding HAZ in Aluminum Welds The Heat-Affected Zone (HAZ) is the unseen neighborhood around a weld where temperatures from the welding process change the metal’s microstructure without melting it. In aluminum welding the HAZ frequently controls whether a joint will meet strength, toughness, or corrosion requirements — more than the …

Read More »Welding Copper and Brass

Welding Copper and Brass Welding copper and brass isn’t like welding your typical mild steel. These two non-ferrous metals bring unique benefits—and their own set of challenges—to the fabrication table. From decorative metalwork to complex industrial systems, copper and brass are utilized in areas where conductivity, corrosion resistance, and aesthetics …

Read More »E6013 Welding Electrode

E6013 Welding Electrode – A Complete Guide The E6013 electrode holds a prominent place in the world of Shielded Metal Arc Welding (SMAW) for one very good reason—it’s accessible, reliable, and produces high-quality welds with minimal fuss. For both professional welders and beginners just learning the craft, E6013 is often …

Read More »E6013 vs E7018

E6013 vs E7018 Stick Welding Electrodes: A Comprehensive Comparison Stick welding, or Shielded Metal Arc Welding (SMAW), remains one of the most widely used welding processes in the world—valued for its simplicity, versatility, and cost-effectiveness. However, the choice of electrode can make or break the weld quality. Among the countless …

Read More »Metallization

What is Metallization: Process, Methods and Applications Metallization is the process of coating or bonding a thin layer of metal onto the surface of a non-metallic or metallic substrate. The primary purpose is to enhance physical properties such as electrical conductivity, corrosion resistance, wear resistance, and aesthetics. Whether it’s for …

Read More »Electrode Selection

Electrode Selection and Application in Welding Electrode Selection is one of the most important decisions in welding. The strength, durability, and appearance of a weld all hinge on using the correct filler material. With countless electrode types designed for specific metals and applications, understanding how to choose and apply them …

Read More »E9018 Welding Electrode

E9018 Welding Electrode: Comprehensive Guide to Specifications, Applications, and Operating Parameters Shielded Metal Arc Welding (SMAW), or stick welding, is a cornerstone process in metal fabrication and repair, valued for its adaptability and simplicity. The consumable electrode is the heart of SMAW, providing filler metal, shielding gases, and flux. Within …

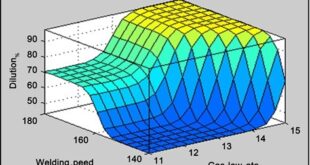

Read More »Weld Metal Dilution

Weld Metal Dilution Rate When you’re laying down a weld, there’s a quiet chemistry dance happening under the hood—the weld metal dilution rate. It might not sound too flashy at first, but trust me, understanding weld dilution can make or break your weld’s quality, strength, and life span. What is …

Read More »Guide to Steel Grades

A Guide to Steel Grades: Low Carbon, High Carbon, and Stainless Steel Steel is one of the most versatile and widely used materials in the world, but not all steel is created equal. For welders, understanding the differences between steel grades is crucial to achieving strong, durable, and high-quality welds. …

Read More » Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders