Stick Welding in the Modern Era: Techniques, Technology, and Innovations Stick welding, also known as Shielded Metal Arc Welding (SMAW), is one of the oldest and most reliable welding processes used today. Though its roots trace back to the early 20th century, stick welding remains a preferred method for numerous …

Read More »Welding Stainless Steel Flanges

Welding Stainless Steel Flanges Welding stainless steel flanges is a critical task in many industries, from petrochemical plants to food processing facilities. These flanges are essential components that connect pipes and ensure leak-proof operations, making their integrity paramount. In this article, we’ll dive deep into the techniques, challenges, and best …

Read More »Copper Pipes and Tubes

Copper Pipes and Tubes Introduction to Copper Pipes and Tubes Copper pipes and tubes are commonly used in various industries, including plumbing, HVAC (heating, ventilation, and air conditioning), and medical fields. While many people recognize the benefits of copper for its durability and corrosion resistance, it’s also a highly significant …

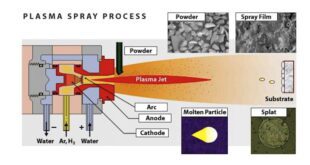

Read More »Plasma Arc Thermal Spraying

Plasma Arc Thermal Spraying Introduction Plasma arc spraying is a cutting-edge technology in the welding field, offering a robust solution for applying protective coatings to various materials. This process plays a critical role in enhancing the durability and performance of components in a wide range of industries. But what exactly …

Read More »Weldability of Aluminum Alloys

Weldability of Aluminum Alloys Aluminum alloys have become integral to various industries due to their unique combination of lightweight, strength, and resistance to corrosion. However, welding these alloys poses certain challenges due to their distinct properties. This article explores the weldability of aluminum alloys, covering the factors that affect their …

Read More »Boiler Tube Welding

Boiler Tube Welding Introduction Boiler tube welding is a critical process in various industries, particularly in power generation, petrochemicals, and manufacturing. Ensuring the integrity of boiler tubes is paramount to maintaining the efficiency, safety, and longevity of boilers. In this comprehensive guide, we’ll delve into the intricacies of boiler tube …

Read More »Pipeline Welding Techniques

Introduction Pipeline welding is a specialized branch of welding that involves joining sections of pipes to create pipelines, which are essential for the transportation of fluids such as oil, gas, water, and chemicals. This technique is critical in numerous industries, including oil and gas, water supply, chemical processing, and construction. …

Read More »Guide to Stainless Steel Welding

Guide to Stainless Steel Welding Introduction Stainless steel, renowned for its durability and resistance to corrosion, is a ubiquitous material in various industries, ranging from construction and automotive to food processing and healthcare. This alloy owes its unique properties to its composition, primarily iron mixed with a minimum of 10.5% …

Read More »Is the E6010 really that good electrode?

Is the E6010 really that good electrode? Introduction When it comes to welding, the choice of electrode can significantly impact the quality and efficiency of the work. One electrode that often comes up in conversations among welders is the E6010 electrode. But is it really that good? Let’s dive into …

Read More »Welding of Stainless Steel 410 vs 316

Welding of Stainless Steel 410 vs 316 Introduction Welding stainless steel is a critical process in various industries, from construction to aerospace. Choosing the right grade of stainless steel is vital to ensure the longevity and integrity of the welded structures. In this article, we’ll delve into the specifics of …

Read More » Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders