E6013 Welding Electrode – A Complete Guide

The E6013 electrode holds a prominent place in the world of Shielded Metal Arc Welding (SMAW) for one very good reason—it’s accessible, reliable, and produces high-quality welds with minimal fuss. For both professional welders and beginners just learning the craft, E6013 is often the first electrode they become comfortable with. It serves as an excellent tool for learning and performing light-to medium-duty welding jobs across a wide range of industries.

What is E6013?

E6013 is a mild steel electrode designed for use in SMAW (stick welding). It’s characterized by a rutile (titanium dioxide-based) flux coating, which provides a stable, easy-to-control arc and smooth weld bead formation. This electrode is suitable for welding thin to moderately thick metal sections and is frequently used in fabrication, maintenance, sheet metal work, and light structural projects. It’s also known for producing a soft arc with minimal spatter and easy slag removal—key features that make it a favorite among beginners and seasoned welders alike.

Importance of E6013 in Arc Welding

In the world of arc welding, E6013 is important because of its forgiving arc characteristics, all-position capability, and versatility on both AC and DC welding machines. Its stable arc performance and excellent bead appearance help improve both the quality and efficiency of welding tasks. It’s widely used in field repairs, structural jobs, sheet metal fabrication, pipe work, and hobbyist projects. The ease with which it handles varying welding positions makes it highly versatile in tight or awkward working environments.

Industry Standards and Classification (AWS A5.1)

The American Welding Society (AWS) classifies electrodes based on their mechanical properties and usability characteristics. E6013 falls under the AWS A5.1 specification, which covers carbon steel electrodes for SMAW. This classification ensures the electrode meets specific criteria for tensile strength, usability, and coating type. Knowing that an electrode meets AWS standards gives welders confidence that it will perform consistently in approved applications.

E6013 Electrode Designation Breakdown

The electrode’s designation—E6013—is not arbitrary. Each number provides valuable information about the electrode’s mechanical strength, position usability, and flux characteristics.

Meaning of ‘E’

The “E” stands for “Electrode.” This tells the welder that the item is an electrode used in electric arc welding. In SMAW, the electrode performs two main roles: it conducts electric current to create the arc, and it melts to become filler metal that fuses with the base metal.

Decoding 60, 1, and 3

Each number following the “E” reveals a specific aspect of the electrode:

60: Indicates the minimum tensile strength of the deposited weld metal—60,000 psi. This value is sufficient for most general-purpose welding jobs where high structural loads are not critical.

1: Means the electrode can be used in all welding positions (flat, horizontal, vertical, and overhead). This all-position capability is especially useful for complex weldments where orientation can’t be easily controlled.

3: Refers to the flux composition and current type. The “3” specifically identifies a rutile (titanium dioxide) flux type that can be used with AC, DCEP (Direct Current Electrode Positive), or DCEN (Direct Current Electrode Negative).

Tensile Strength

The “60” indicates the weld metal can withstand 60,000 psi of tensile stress before failure. This is adequate for a wide range of mild steel applications, from light brackets and frames to automotive parts and general repair work.

Because E6013 is an all-position electrode (“1”), it can be used for overhead, vertical-up, and vertical-down welding. This is especially useful in fabrication work where positional constraints make flat welding impossible.

Flux Characteristics

The rutile coating denoted by the “3” helps create a smooth, steady arc that is easy to control. It also forms a protective slag that shields the weld from atmospheric contamination and is very easy to remove—sometimes lifting off by itself as the weld cools.

Composition and Coating of E6013

Understanding the materials used in E6013’s construction explains why it performs the way it does.

Core Wire Material

The electrode core is made of mild steel. This steel rod serves as the filler material, melting during the arc process and combining with the base metal to form the weld joint. The chemical composition typically includes low carbon content to ensure good weldability and ductility.

Rutile-Based Flux Coating

The flux coating contains titanium dioxide (rutile), which plays several important roles:

It stabilizes the arc.

It forms a protective slag that shields the weld pool.

It helps in the formation of a smooth, uniform bead.

It improves arc restart characteristics.

The rutile flux also enables welding with both AC and DC power sources, making E6013 especially adaptable to different machines and job sites.

Coating Thickness and Its Effects

The thickness of the flux coating affects how easily the arc starts and how much slag is produced. Thicker coatings can offer better arc shielding but may require slightly more power to maintain a steady arc. For E6013, the balanced thickness is optimized for smooth welds, easy handling, and consistent bead formation.

Welding Characteristics of E6013

E6013 is known for its smooth and forgiving arc, making it an ideal choice for welding in any position.

Arc Behavior

The arc produced by E6013 is soft and stable. It doesn’t dig aggressively into the base metal, which minimizes the risk of burn-through on thin sections. This also helps in maintaining a controlled weld pool, making it easier for beginners to manage.

Slag Formation and Removal

One of the standout features of E6013 is its slag system. The slag is self-lifting and detaches easily, leaving behind a clean bead. This is especially useful in multi-pass welds where slag must be removed between passes, saving time and effort.

Penetration Profile and Bead Appearance

E6013 provides moderate penetration, which is usually just right for sheet metal and lighter gauge steel. It produces a wide, flat bead with minimal undercut and good tie-in at the edges. The weld appearance is generally smooth and aesthetically pleasing.

Recommended Welding Parameters

Welding parameters for E6013 vary slightly depending on diameter, thickness of base material, and position.

Suitable Current Range (Amps)

2.5 mm (3/32”): 40–90 A

3.2 mm (1/8”): 90–130 A

4.0 mm (5/32”): 130–180 A

These ranges offer flexibility across machine types. Always fine-tune based on position, joint fit-up, and travel speed.

Voltage and Polarity Recommendations

While voltage is often set automatically by the machine (in transformer-type welders), a stable arc length ensures voltage consistency. Maintain a short arc for best results.

AC vs DC Performance

E6013 can run on both AC and DC machines. This makes it usable on even the most basic welding setups, including transformer-based AC stick welders commonly found in home shops.

DCEP, DCEN, and AC Compatibility

DCEP (Electrode Positive): Provides deeper penetration and better arc control.

DCEN (Electrode Negative): Offers less penetration and may be better for thinner materials.

AC: Balanced performance and excellent for general-purpose work.

Applications and Use Cases

E6013 is used across industries due to its all-around versatility.

Structural Fabrication

It’s often used in light structural fabrication for frames, platforms, and fixtures that don’t require deep penetration or ultra-high strength.

Automotive Repairs

This electrode is perfect for automotive panels, exhaust repairs, and small chassis modifications. Its smooth arc and controlled penetration prevent burn-through on thin metals.

Thin Sheet Welding and General Repairs

From toolboxes to furniture, farm equipment to pipelines (non-critical), E6013 is widely used for its clean welds and ease of use.

Advantages of Using E6013 Electrodes

The benefits of E6013 make it a favorite across many user levels.

Ease of Use for Beginners

It’s one of the most forgiving electrodes in terms of arc starts, restarts, and travel speed. Beginners find it easier to control compared to electrodes like E6010 or E7018.

Smooth Finish and Low Spatter

The arc is quiet and controlled, leading to smooth beads with very little spatter. Cleanup is minimal—often just brushing off the slag.

Versatile Position Welding

Its ability to weld in all positions adds to its usefulness, especially for welders working on complex or restricted joints.

Limitations and Challenges

Despite its advantages, E6013 isn’t suitable for every situation.

Not Suitable for Deep Penetration

Due to its soft arc, it lacks the digging action needed for welding thick materials or heavy structures.

Poor Performance on Rusty/Oily Surfaces

The rutile flux doesn’t tolerate contamination well. For rusty, painted, or oily metals, electrodes like E6011 perform better.

Requires Frequent Re-strikes on Large Welds

In long welds, E6013 may require frequent re-striking, which can be problematic if the tip isn’t kept clean. This slows down productivity.

Best Practices for Welding with E6013

To get the best results, follow these expert recommendations.

Proper Storage and Handling

Keep electrodes in a dry place. If they absorb moisture, dry them in an electrode oven at ~250°F (120°C) for 1–2 hours.

Recommended Travel Speed and Angle

Maintain a travel angle of 10–15° (drag technique) with a steady hand. Adjust speed to ensure proper fusion and avoid cold lap or excessive buildup.

Pre-cleaning and Fit-Up Tips

Remove rust, paint, and oil before welding. For tight fit-ups, E6013 performs well without excessive manipulation.

E6013 vs Other Electrodes

Let’s compare E6013 to its close alternatives.

E6013 vs E6011

E6011: Deep penetration, suitable for dirty metals, cellulose-based flux.

E6013: Smoother arc, cleaner weld, rutile-based flux, better bead appearance.

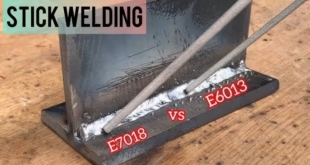

E6013 vs E7018

E7018: Higher tensile strength (70,000 psi), iron powder flux, low hydrogen, better for critical structural work.

E6013: Easier to use, better for thin metals, and doesn’t require oven storage.

When to Choose E6013 Over Others

Choose E6013 when working with clean, thin metals, and when a visually pleasing weld is needed. It’s ideal for light-duty work, especially with AC machines.

FAQs

Can I use E6013 for pipe welding?

Yes, but only for non-critical pipes or cosmetic passes. For root passes or pressure-rated joints, other rods like E6010 or E7018 are better.

Does E6013 need special storage like E7018?

No, E6013 is less sensitive to moisture and doesn’t require sealed ovens unless it’s been exposed to high humidity.

What is the best motion for E6013 welding?

A straight drag or slight weave works well. Excessive weaving is not necessary and can result in poor fusion.

Is E6013 a low-hydrogen electrode?

No. It is not classified as a low-hydrogen electrode and should not be used where hydrogen-induced cracking is a concern.

Can beginners learn welding with E6013?

Absolutely. Its stable arc, low spatter, and easy slag removal make it one of the best learning electrodes.

Conclusion

E6013 is a balanced, easy-to-use, and versatile electrode designed for a wide range of welding tasks. Its soft arc, smooth bead appearance, and ability to run on AC or DC make it ideal for hobbyists, students, and professional welders alike. While it’s not intended for high-strength or deep-penetration applications, it shines in light fabrication and general-purpose work. When used properly, E6013 delivers clean, consistent results every time.

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders