E7024 Welding Electrode: Complete Technical Guide

The E7024 welding electrode is a high-deposition, iron-powder, low-hydrogen-type electrode widely used in Shielded Metal Arc Welding (SMAW) for flat and horizontal fillet welds. It is designed for productivity rather than positional versatility, making it a preferred choice in fabrication environments where speed, smooth bead appearance, and high deposition rates are critical.

In practical terms, E7024 behaves like a “production electrode.” Where other electrodes emphasize control or all-position usability, E7024 focuses on laying down a lot of weld metal quickly and efficiently, particularly on thicker sections of carbon steel.

AWS Classification and Meaning of E7024

Breakdown of the AWS E7024 Designation

The classification E7024 follows the AWS A5.1 standard for carbon steel electrodes. Each digit conveys specific technical information.

Tensile Strength Rating

“70” indicates a minimum tensile strength of 70,000 psi (≈ 483 MPa).

This makes E7024 suitable for most structural and fabrication-grade carbon steels.

Welding Position Capability

“2” means the electrode is designed for flat position and horizontal fillet welds only.

This restriction exists because of its heavy iron-powder flux, which produces a fluid weld pool.

Flux Coating and Current Type

“4” signifies a rutile-based, iron powder flux coating.

It also indicates compatibility with AC and DC (DCEP) welding currents.

Chemical Composition of E7024 Electrode

Core Wire Composition

The core wire of E7024 is generally a low-carbon steel, engineered to deliver good ductility and strength without excessive hardness. Typical elements include:

Carbon (C): Low to moderate

Manganese (Mn): Improves strength and deoxidation

Silicon (Si): Enhances weld pool cleanliness

Flux Coating Constituents

The flux coating is where E7024 truly distinguishes itself. It contains:

High iron powder content (30–50%)

Rutile (titanium dioxide)

Deoxidizers and arc stabilizers

Mechanical Properties of E7024 Weld Metal

Tensile Strength

Minimum: 70,000 psi

This meets the requirements for most structural steel applications.

Yield Strength

Typically around 58,000–62,000 psi

This provides adequate resistance to plastic deformation under load.

Elongation and Impact Properties

Elongation: 22–28%

Impact toughness: Moderate, but not intended for low-temperature or critical impact applications

E7024 is strong and ductile but not designed for pressure vessels or dynamic loading environments.

Flux Coating Characteristics of E7024

Iron Powder High Deposition Flux

The defining feature of E7024 is its iron powder flux coating, which dramatically increases weld metal deposition.

Role of Iron Powder in Deposition Rate

Iron powder melts into the weld pool, allowing:

Higher travel speeds

Thicker weld beads

Fewer passes required

Welding Positions and Usability

Flat Position Welding

E7024 excels in flat (1G / 1F) welding. The fluid slag spreads evenly, producing a wide, flat bead with excellent appearance.

Horizontal Fillet Welding

It also performs well in horizontal fillet (2F) welds, especially for long, continuous joints.

However, it is not suitable for vertical or overhead welding, as the molten slag becomes difficult to control.

Polarity and Power Source Compatibility

AC Welding Capability

E7024 runs exceptionally well on AC power, making it ideal for older transformer-type welding machines.

DC Electrode Positive (DCEP)

It also performs efficiently on DC+, providing:

Stable arc

Smooth metal transfer

Reduced spatter

Advantages & Disadvantages of E7024

Advantages

Extremely high deposition rate

Smooth, wide bead profile

Easy slag removal

Minimal spatter

Excellent for long welds

Reduced operator fatigue due to drag-type technique

Disadvantages

Despite its strengths, E7024 has limitations:

Restricted to flat and horizontal positions

Not suitable for root passes

Lower impact toughness than low-hydrogen electrodes

Not recommended for critical or cyclic load applications

Typical Applications of E7024 Electrode

Structural Steel Fabrication

Used for beams, plates, and frames where high productivity is required.

Shipbuilding and Heavy Fabrication

Ideal for long fillet welds on decks, stiffeners, and bulkheads.

Repair and Maintenance Work

Common in workshops for fast buildup and surface welding on carbon steel.

Recommended Welding Parameters

Amperage Range by Electrode Size

| Electrode Size | Current Range (A) |

|---|---|

| 3.2 mm (1/8”) | 140–190 A |

| 4.0 mm (5/32”) | 180–260 A |

| 5.0 mm (3/16”) | 240–320 A |

Travel Speed and Arc Length

Use a short arc

Maintain steady travel speed

Employ a slight drag angle (5–15°)

Storage, Handling, and Moisture Control

E7024 is less moisture-sensitive than low-hydrogen electrodes, but proper storage is still important:

Keep in dry conditions

Avoid prolonged exposure to humidity

No baking usually required unless specified by manufacturer

Comparison with Other E70XX Electrodes

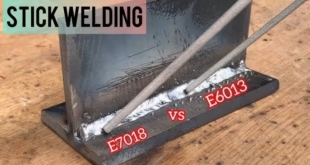

E7024 vs E7018

E7024: Higher deposition, limited positions

E7018: Low hydrogen, all positions, higher toughness

E7024 vs E6013

E7024: Stronger, heavier deposition

E6013: Easier arc start, better for thin materials

E7024 vs E7014

Both are iron powder electrodes

E7024 has higher iron content and deposition rate

E7024 vs E7014 vs E7018

| Feature | E7024 | E7014 | E7018 |

|---|---|---|---|

| Tensile Strength | 70,000 psi | 70,000 psi | 70,000 psi |

| Flux Type | Rutile + High Iron Powder | Rutile + Iron Powder | Low Hydrogen |

| Welding Positions | Flat, Horizontal | Flat, Horizontal, Vertical | All Positions |

| Deposition Rate | ⭐⭐⭐⭐⭐ (Very High) | ⭐⭐⭐⭐ (High) | ⭐⭐ (Moderate) |

| Slag Removal | Very Easy | Easy | Moderate |

| Moisture Sensitivity | Low | Low | Very High |

| Typical Skill Level | Beginner–Intermediate | Beginner | Intermediate–Advanced |

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders