How to measure Fillet Weld Size

Welding is an essential process in many industries, and fillet welds are one of the most common types of welds used to join metal parts. However, the quality of a fillet weld largely depends on its size, which directly affects its strength and functionality. This comprehensive guide covers everything you need to know about accurately measuring fillet weld sizes.

Introduction to Fillet Welds

What Is a Fillet Weld?

A fillet weld is a triangular weld used to join two surfaces that meet at an angle, typically 90 degrees. These welds are commonly found in T-joints, lap joints, and corner joints. The fillet weld doesn’t require the edges of the metal pieces to be beveled, making it faster and more economical than other weld types, such as groove welds.

Fillet welds can be applied in various positions, including flat, vertical, overhead, and horizontal. Their versatility and ease of application make them indispensable in structural fabrication, shipbuilding, and automotive industries.

Importance of Measuring Fillet Welds

The strength of a fillet weld depends on its size. If a weld is undersized, it may not withstand the intended load, leading to structural failure. Conversely, an oversized weld wastes material and can introduce stress and distortion to the welded structure. Proper measurement ensures the weld meets design and safety requirements without compromising efficiency.

Common Fillet Weld Types

Flat Fillet Weld

Flat fillet welds are applied on a horizontal surface with the weld bead lying flat. These are the easiest to execute because gravity helps to keep the molten metal in place. They’re ideal for large projects like ship hulls and bridges.

Vertical Fillet Weld

Vertical fillet welds are applied on vertical surfaces. The challenge with these welds lies in controlling the weld pool to prevent sagging or dripping. This requires a skilled welder and often specific techniques such as upward or downward welding methods.

Overhead Fillet Weld

Overhead fillet welds involve welding on the underside of a surface. These are among the most challenging as gravity works against the welder, making it difficult to control the molten pool. Overhead welds require precision and often lead to higher fatigue for the welder.

Understanding Fillet Weld Size

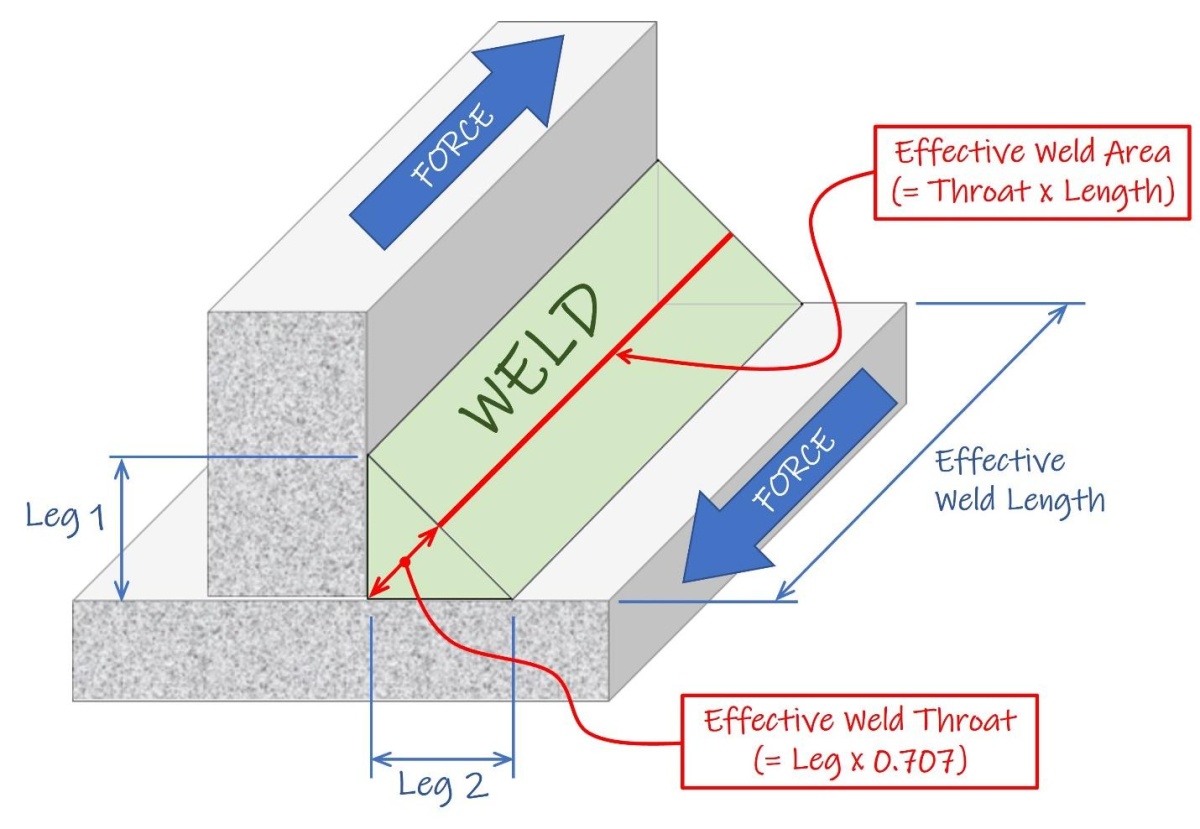

Leg Length

The leg length is one of the most crucial measurements in a fillet weld. It refers to the distance from the weld root (where the two metal pieces meet) to the toe of the weld along each leg of the triangle. Both legs of the fillet weld should ideally have the same length unless otherwise specified.

Why Leg Length Matters

The leg length determines the overall size and load-bearing capacity of the weld. A larger leg length generally means a stronger weld, but it also consumes more material and may not be necessary for all applications. Correct leg length ensures the weld can handle the forces acting upon it without over-engineering.

Throat Thickness

The throat thickness is the shortest distance from the weld root to the face of the weld. For a theoretical perfect 45-degree fillet weld, this thickness is approximately 70.7% of the leg length.

Impact of Throat Thickness on Weld Strength

Throat thickness is critical because it determines the weld’s ability to withstand shear and tensile forces. An insufficient throat thickness compromises the weld’s strength, while an overly thick weld can lead to material waste and potential structural issues.

Tools for Measuring Fillet Weld Size

Fillet Weld Gauges

Fillet weld gauges are specifically designed tools that allow for quick and accurate measurement of weld size. They are simple to use and come in various designs for measuring different aspects of a weld.

How to Use a Fillet Weld Gauge

To measure leg length, align the gauge along the weld’s legs. For throat thickness, some gauges have specific notches or rulers that help in determining this value. Place the gauge in the weld area and observe the measurements to ensure they meet the design specifications.

Types of Fillet Weld Gauges

There are fixed gauges, which are pre-set for specific weld sizes, and adjustable gauges, which can be configured for various measurements. Some advanced gauges also include digital readouts for increased accuracy.

Calipers and Other Precision Tools

Calipers can measure the leg length of smaller welds with high precision. Digital calipers provide more accurate and easier-to-read measurements, especially for intricate work.

Visual Inspection Techniques

Experienced welders often use visual inspection as a quick method to check weld quality. While it doesn’t provide numerical accuracy, visual inspection helps in identifying obvious defects, such as underfill, porosity, or incorrect bead shape.

Step-by-Step Process to Measure Fillet Weld Size

Preparing the Weld for Measurement

Before measuring, ensure the weld is clean and free from slag, spatter, or other debris. A clean weld surface allows for more accurate measurements and better inspection of weld quality.

Measuring the Leg Length

Use a fillet weld gauge or caliper to measure the distance from the weld root to the weld toe along both legs. Check that both leg lengths match the specified dimensions in the design.

Determining the Throat Thickness

Use the formula for throat thickness:

Throat Thickness=Leg Length×0.707

For example, if the leg length is 10 mm:

Throat Thickness=10×0.707=7.07 mm

This value ensures the weld’s strength and compliance with design requirements.

Standard Fillet Weld Sizes

Here’s a reference table to help you quickly determine throat thickness based on leg length:

| Leg Length (mm) | Throat Thickness (mm) | Weld Type |

|---|---|---|

| 5 | 3.54 | Small Fillet Weld |

| 10 | 7.07 | Medium Fillet Weld |

| 15 | 10.61 | Large Fillet Weld |

| 20 | 14.14 | Extra Large Fillet Weld |

Common Challenges and Mistakes

Misinterpreting Measurements

Errors often occur when tools are improperly used or misread. For instance, using an incorrect gauge size can result in faulty measurements, leading to non-compliant welds.

Overlooking Weld Defects

Defects such as cracks, undercut, or porosity can compromise the weld’s integrity. These defects may not only weaken the structure but also affect measurement accuracy.

Standards and Codes for Fillet Weld Size

Overview of Industry Standards

Organizations like the American Welding Society (AWS) and ISO provide guidelines to ensure that fillet welds meet quality and safety requirements. These standards specify acceptable weld sizes, tolerances, and inspection criteria.

How to Ensure Compliance

Regular training, inspections, and adherence to industry codes ensure welds meet all safety and performance requirements. Following these guidelines also minimizes the risk of costly rework or structural failure.

Tips for Accurate Measurement

Best Practices for Beginners

Start by mastering basic tools like fillet weld gauges. Focus on understanding how to interpret measurements and how each measurement affects weld quality.

Avoiding Common Pitfalls

Always double-check your readings and ensure your tools are properly calibrated. Avoid rushing through the measurement process, as small errors can lead to significant issues in the weld’s performance.

FAQs

How do you know if a fillet weld is too small?

A fillet weld is too small if its leg length or throat thickness doesn’t meet the specified design criteria, potentially leading to structural failure.

Can you measure fillet weld size without a gauge?

Yes, though less precise, you can use tools like calipers or rely on visual inspection. However, a fillet weld gauge is recommended for accuracy.

What happens if the fillet weld is too large?

Oversized welds waste material and can introduce stress, leading to distortion or cracking in the base material.

Are fillet weld gauges expensive?

No, they are affordable and widely available. They are a worthwhile investment for ensuring accurate and compliant welds.

How often should fillet welds be inspected?

Fillet welds should be inspected regularly, especially at key project stages or when structural integrity is critical.

Conclusion

Measuring fillet weld size is a fundamental skill that ensures the quality, safety, and reliability of your welds. By mastering the tools and techniques for accurate measurement, you’ll not only meet industry standards but also produce welds that stand the test of time.

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders