What is High Frequency Welding?

Introduction

High-frequency welding is a specialized welding process that utilizes electromagnetic waves to join materials. This advanced technique has gained prominence in various industries due to its efficiency, precision, and versatility. Understanding the fundamentals of high-frequency welding is crucial to appreciate its significance in modern manufacturing.

Definition of High-Frequency Welding

High-frequency welding, also known as radiofrequency (RF) welding or induction welding, is a method where electromagnetic waves at high frequencies are employed to generate heat and fuse materials together. This process is particularly effective for welding thermoplastic and synthetic materials. The high-frequency energy induces molecular movement in the material, resulting in a strong and durable bond.

Basic Principles of High-Frequency Welding

High-frequency welding operates on a set of fundamental principles that involve the interaction of electromagnetic waves with materials, resulting in a controlled and efficient welding process.

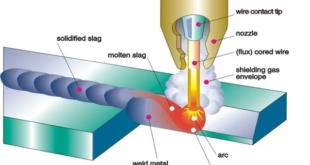

Overview of High-Frequency Welding Process

High-frequency welding is a technique that relies on the generation of heat through the application of electromagnetic waves. The process typically involves the following key steps:

- Material Preparation: Before welding, the materials to be joined are properly prepared, ensuring clean and precise edges for optimal fusion.

- Tooling Setup: The materials are placed in a specialized tooling setup, which may include electrodes or molds designed to hold and press the materials together during the welding process.

- Application of High-Frequency Energy: High-frequency energy is applied to the materials using an electrode or induction coil. This energy induces rapid molecular movement within the materials, generating heat.

- Fusion of Materials: As the materials heat up, they soften and fuse together at the desired joints. The pressure from the tooling setup ensures proper contact between the materials during the welding process.

- Cooling and Solidification: After fusion, the welded materials are allowed to cool and solidify, forming a strong and durable bond.

Role of Electromagnetic Waves

Electromagnetic waves play a crucial role in the high-frequency welding process. In this context, radiofrequency (RF) or high-frequency waves are employed to generate heat within the materials. The key aspects of the role of electromagnetic waves include:

- Energy Transfer: Electromagnetic waves transfer energy to the molecules of the materials being welded. This energy causes the molecules to vibrate rapidly, generating heat.

- Selectivity of Materials: Different materials respond differently to electromagnetic waves based on their composition and molecular structure. The selectivity allows for precise control over the welding process, making high-frequency welding suitable for a variety of materials.

- Uniform Heating: Electromagnetic waves facilitate uniform heating across the joint, ensuring consistent fusion and minimizing the risk of uneven bonds.

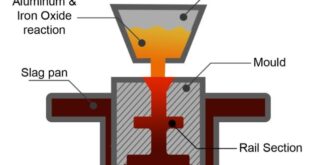

Heating Mechanism

The heating mechanism in high-frequency welding is primarily based on the principle of dielectric heating. Dielectric materials, such as certain plastics, are poor conductors of electricity. When subjected to high-frequency electromagnetic fields, the molecules in these materials attempt to align with the changing field, leading to rapid movement and friction. This molecular motion results in heat generation, causing the materials to soften and ultimately bond together.

Types of High Frequency Welding

High-frequency welding encompasses different methods, each with unique characteristics and applications. The two primary types are Radio Frequency (RF) welding and High-Frequency (HF) welding.

Radio Frequency (RF) Welding

- Explanation of RF Welding: Radio Frequency (RF) welding is a high-frequency welding technique that employs electromagnetic energy in the radiofrequency range (typically 13.56 MHz). The process involves the use of an RF generator to produce an alternating electric field, creating heat within dielectric materials. The key steps in RF welding include:

- Material Placement: The materials to be welded are positioned between electrodes or in a specialized tooling setup.

- Application of RF Energy: The RF generator applies electromagnetic energy to the materials, inducing heat through dielectric heating.

- Bonding Process: The materials soften and fuse at the desired joints, forming a strong and durable bond.

- Common Applications: RF welding finds widespread applications in various industries due to its versatility and efficiency. Common applications include:

- Medical Industry: Production of medical bags, blood and IV bags, inflatable splints, and other medical devices.

- Automotive Sector: Manufacturing of airbags, door panels, and interior components.

- Textile and Apparel: Joining of fabrics for products like rainwear, inflatable structures, and sportswear.

High-Frequency (HF) Welding

- Overview of HF Welding: High-Frequency (HF) welding, also known as induction welding, operates at higher frequencies than RF welding, typically in the range of 27.12 MHz. This technique utilizes an induction coil to create an alternating magnetic field, generating heat through the principle of induction. The HF welding process involves:

- Material Preparation: The materials are prepared and placed in a tooling setup.

- Induction Heating: The induction coil produces a rapidly changing magnetic field, inducing heat in conductive materials.

- Joint Fusion: The materials soften and fuse at the desired joints under pressure, resulting in a strong welded connection.

- Specific Applications: High-Frequency welding has specific applications across various industries, owing to its adaptability to different materials and efficient heating mechanism. Some specific applications include:

- Packaging Industry: Welding of blister packs, clamshell packaging, and other plastic packaging materials.

- Electronics Manufacturing: Production of electronic components, such as mobile phone covers and smart cards.

- Footwear Industry: Joining of shoe components, including soles, uppers, and straps.

Advantages of High-Frequency Welding

High-frequency welding boasts several advantages that make it a preferred choice in various industries. These advantages contribute to its widespread adoption and effectiveness in manufacturing processes.

Speed and Efficiency

One of the primary advantages of high-frequency welding is its remarkable speed and efficiency in joining materials. The rapid and controlled application of electromagnetic energy allows for quick heating and fusion of materials. This high-speed process is particularly beneficial in industries where large volumes of products need to be manufactured within tight timelines.

- Increased Production Rates: High-frequency welding enables faster production cycles, leading to increased output and productivity.

- Reduced Processing Time: The quick heating and cooling cycles reduce the overall processing time, contributing to efficient manufacturing operations.

- Just-In-Time Production: The speed of high-frequency welding aligns well with just-in-time production models, allowing manufacturers to respond promptly to market demands.

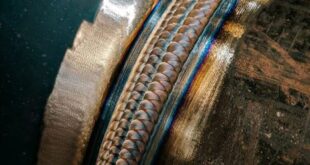

Precision and Consistency

Another notable advantage of high-frequency welding is its ability to provide precise and consistent results. The controlled application of electromagnetic energy ensures uniform heating and fusion of materials, leading to reliable and high-quality welds.

- Uniform Heating: Electromagnetic waves enable even heating across the material, minimizing the risk of uneven joints and ensuring consistent bonding.

- Repeatable Process: The automated nature of high-frequency welding allows for precise control over each welding cycle, ensuring repeatability and consistency in the final product.

- Tight Tolerances: The precision of high-frequency welding makes it suitable for applications with tight tolerances, where accurate joint dimensions are crucial.

Cost-Effectiveness

High-frequency welding offers cost-effective solutions for various manufacturing processes. The combination of speed, efficiency, and precision contributes to overall cost savings in both production and operational aspects.

- Reduced Labor Costs: The automated nature of high-frequency welding minimizes the need for extensive manual labor, leading to reduced labor costs.

- Material Savings: The efficiency of the welding process reduces material waste, optimizing material usage and contributing to cost-effectiveness.

- Energy Efficiency: High-frequency welding often requires less energy compared to traditional welding methods, contributing to lower operational costs.

Limitations and Challenges of High-Frequency Welding

While high-frequency welding offers numerous advantages, it is essential to recognize its limitations and challenges. Understanding these aspects is crucial for manufacturers to make informed decisions regarding the suitability of high-frequency welding for specific applications.

Material Compatibility

- Material Selection Constraints: High-frequency welding is most effective with certain materials, particularly those that are dielectric or have good electrical conductivity. Materials that do not respond well to dielectric heating may pose challenges in achieving strong and reliable welds.

- Limited Material Thickness: High-frequency welding may be less suitable for very thick materials. The depth of penetration of electromagnetic waves may limit the welding effectiveness in materials with substantial thickness, affecting the overall strength of the weld.

- Material Sensitivity: Some materials may be sensitive to the heating process induced by high-frequency waves, potentially leading to issues such as degradation or changes in material properties.

Equipment and Maintenance

- Initial Equipment Costs: The setup for high-frequency welding can involve significant initial costs, including the acquisition of specialized machinery and tooling. This can be a barrier for small-scale or budget-constrained manufacturers.

- Complex Equipment: High-frequency welding machines can be complex and require skilled operators for optimal performance. Training and expertise are essential to operate and maintain the equipment effectively.

- Regular Maintenance Requirements: Like any machinery, high-frequency welding equipment requires regular maintenance to ensure consistent performance. Maintenance tasks can include checking and replacing components like electrodes and coils.

Environmental Considerations

- Emission of Electromagnetic Waves: The emission of electromagnetic waves during high-frequency welding raises concerns about potential interference with nearby electronic equipment. Adequate precautions and shielding may be necessary to minimize these effects.

- Energy Consumption: While high-frequency welding is generally energy-efficient compared to some traditional welding methods, its continuous operation may still contribute to significant energy consumption. Manufacturers need to consider the environmental impact and explore ways to optimize energy usage.

- Waste and Recycling: Certain materials used in high-frequency welding, especially in packaging applications, may pose challenges for recycling. Understanding and addressing the environmental impact of waste generated during the welding process is crucial.

Industries and Applications of High-Frequency Welding

High-frequency welding finds extensive use across various industries, offering efficient and precise solutions for joining materials. Here are specific applications in key industries:

Automotive Industry

- Airbag Manufacturing: High-frequency welding is employed in the production of airbags, where quick and precise bonding is crucial for ensuring the safety and reliability of these critical automotive components.

- Door Panel Assembly: Automotive door panels often consist of multiple materials that need to be securely joined. High-frequency welding allows for the rapid and accurate assembly of door panels, contributing to the overall structural integrity of the vehicle.

- Interior Components: The automotive sector utilizes high-frequency welding for manufacturing various interior components, including seat covers, dashboard elements, and other intricate parts that require efficient and consistent bonding.

- Convertible Roof Sealing: In convertible vehicles, high-frequency welding is employed to seal and bond the convertible roof material, ensuring a watertight and durable connection.

Packaging Industry

- Blister Pack Sealing: High-frequency welding is commonly used in the packaging industry to create sealed seams in blister packs. This ensures product integrity and extends the shelf life of pharmaceuticals and other consumer goods.

- Clamshell Packaging: The production of clamshell packaging, widely used in retail for electronics, hardware, and other products, involves high-frequency welding for securely sealing the plastic shells around the items.

- Food Packaging: In the food industry, high-frequency welding is applied to create airtight and secure seals in packaging materials, preserving the freshness and quality of food products.

- Inflatable Packaging: Certain types of packaging, especially those used for shipping delicate items, rely on high-frequency welding to create inflatable or cushioned packaging materials.

Medical Devices and Equipment

- Medical Bag Manufacturing: High-frequency welding plays a vital role in the production of medical bags, including blood and IV bags. The process ensures sterile and secure seals, meeting the stringent quality standards required in the medical field.

- Inflatable Splints and Medical Devices: The medical industry utilizes high-frequency welding for manufacturing inflatable splints and various medical devices, where precision and reliability are critical for patient care.

- Surgical Equipment Assembly: High-frequency welding is applied in the assembly of surgical equipment and devices, contributing to the production of components with high strength and hygiene standards.

- Patient Support Surfaces: Certain medical devices, such as pressure-relief mattresses and other patient support surfaces, benefit from the efficient and controlled bonding provided by high-frequency welding.

Comparison with Other Welding Techniques

High-frequency welding stands out among various welding techniques, offering unique advantages and characteristics. Here, we compare high-frequency welding with traditional welding methods and ultrasonic welding.

High-Frequency Welding vs. Traditional Welding

Heating Mechanism:

- High-Frequency Welding: Utilizes electromagnetic waves for dielectric heating, leading to rapid and controlled heating of materials.

- Traditional Welding: Typically involves the direct application of heat through flames, arcs, or electrical resistance, which may result in slower and less precise heating.

Speed and Efficiency:

- High-Frequency Welding: Known for its speed and efficiency, allowing for quick production cycles.

- Traditional Welding: May have longer processing times, particularly in methods such as arc welding or gas welding.

Precision and Consistency:

- High-Frequency Welding: Offers high precision and consistency due to controlled electromagnetic energy application.

- Traditional Welding: May require skilled operators to achieve precision, and consistency can be challenging in certain applications.

Material Compatibility:

- High-Frequency Welding: Well-suited for joining thermoplastics and synthetic materials through dielectric heating.

- Traditional Welding: Broad applicability but may have limitations based on material properties and compatibility.

Equipment Complexity:

- High-Frequency Welding: Involves specialized equipment such as RF generators and induction coils, which can be complex.

- Traditional Welding: Equipment varies widely but can range from simple setups for processes like gas welding to more complex machinery for arc welding.

Environmental Impact:

- High-Frequency Welding: Generally considered more energy-efficient, potentially leading to lower environmental impact.

- Traditional Welding: Environmental impact depends on the specific welding method, with some processes emitting more pollutants than others.

High-Frequency Welding vs. Ultrasonic Welding

Joining Mechanism:

- High-Frequency Welding: Relies on dielectric heating induced by electromagnetic waves.

- Ultrasonic Welding: Involves the generation of high-frequency mechanical vibrations to create frictional heat, resulting in material fusion.

Materials:

- High-Frequency Welding: Suited for a wide range of materials, especially thermoplastics and synthetic materials.

- Ultrasonic Welding: Effective for plastics, particularly where high-speed welding of small to medium-sized parts is required.

Speed:

- High-Frequency Welding: Known for rapid processing and high-speed production.

- Ultrasonic Welding: Generally fast but may have limitations on the size and complexity of parts.

Equipment Complexity:

- High-Frequency Welding: Involves specialized equipment like RF generators or induction coils.

- Ultrasonic Welding: Typically involves a less complex setup with an ultrasonic horn and anvil.

Joint Strength:

- High-Frequency Welding: Creates strong and durable bonds suitable for various applications.

- Ultrasonic Welding: Offers strong and reliable joints, especially in applications with small and intricate components.

Application Size:

- High-Frequency Welding: Suitable for both small and large-scale applications.

- Ultrasonic Welding: More commonly used for smaller parts due to the limitations of ultrasonic technology in handling larger components.

FAQs

Is high-frequency welding suitable for all materials?

High-frequency welding is versatile and can be applied to various materials, including metals and plastics, making it suitable for a wide range of applications.

What challenges are commonly associated with high-frequency welding?

Common challenges include maintaining consistency in weld quality, addressing electromagnetic interference, and ensuring proper equipment maintenance.

How does high-frequency welding contribute to sustainability?

HFW reduces the carbon footprint by minimizing energy consumption and waste, aligning with environmentally conscious practices.

Are there specific safety measures unique to high-frequency welding?

While general welding safety measures apply, additional precautions involve managing electromagnetic fields and using specialized protective gear.

Where can I get access to high-frequency welding training and certification?

Reputable welding institutions and industry-specific training centers offer courses and certifications in high-frequency welding. For online options, check accredited platforms.

Conclusion

In conclusion, high-frequency welding stands as a pivotal technology in the manufacturing realm, driving innovation, efficiency, and quality across diverse industries. Its ongoing evolution and adaptation to emerging trends position it as a key player in shaping the future of modern manufacturing processes.

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders