Root Pass vs Hot Pass vs Capping: A Complete Guide

Introduction

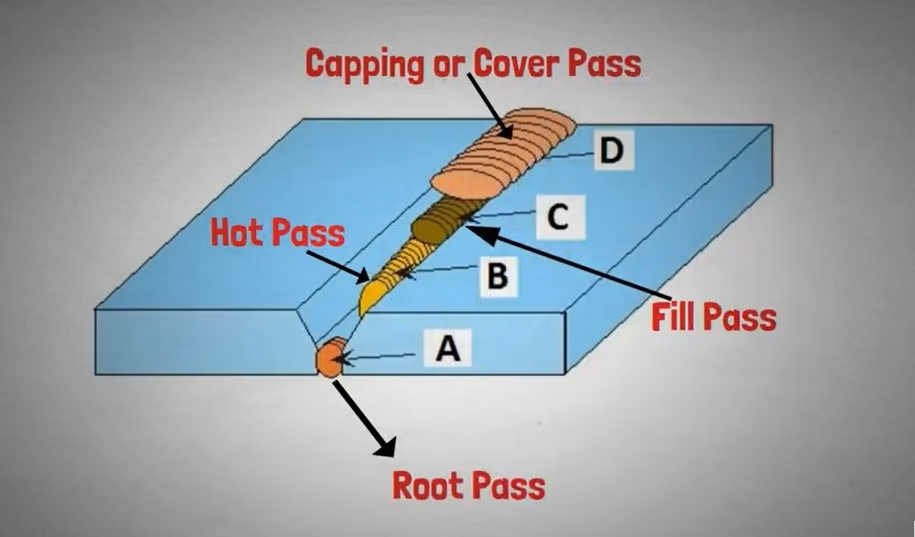

Welding is an art and a science. When it comes to multi-pass welding, the terms “root pass,” “hot pass,” and “capping” often come up. But what do they mean, and why are they so important? Understanding the roles and techniques of each pass is crucial for achieving strong, reliable, and visually appealing welds. Whether you’re a novice welder or a seasoned professional, this guide will break down these terms and help you perfect your craft.

What is a Root Pass?

Definition and Purpose

The root pass is the foundation of any multi-pass weld. It’s the first layer of weld metal that joins the base metals, creating a strong bond and ensuring proper penetration. Think of it as laying the groundwork for a sturdy building — if the base isn’t solid, the structure will fail.

Key Techniques for Root Pass

To achieve a successful root pass, you need precision and focus:

- Electrode Angle: Maintain a consistent angle to direct heat effectively.

- Amperage Settings: Too low, and you risk poor penetration; too high, and you might burn through the material.

Common Challenges in Root Pass

- Incomplete Penetration: This happens when the weld doesn’t fully bond with the base metals.

- Burn-Through Issues: Excessive heat can melt through the material, weakening the joint.

What is a Hot Pass?

Definition and Purpose

The hot pass is the second welding layer, applied to reinforce the root pass. It smooths out imperfections and ensures a strong connection between the root and subsequent layers. Imagine smoothing out the rough edges of a freshly cut piece of wood — the hot pass does just that for the root weld.

Techniques for Effective Hot Pass

- Heat Control: Too much heat can distort the weld; too little may leave slag.

- Travel Speed: Maintain a steady speed to avoid inconsistencies.

Common Problems in Hot Pass

- Slag Entrapment: Slag left from the root pass can get trapped if not properly cleaned.

- Poor Blending: Uneven transitions between passes can weaken the weld.

What is Capping?

Definition and Purpose

Capping is the final welding layer, providing both aesthetic appeal and protection. It seals the weld joint and gives it a finished look, much like the icing on a cake.

Techniques for Quality Capping

- Bead Placement: Consistent and well-spaced beads create a uniform appearance.

- Surface Finish: A smooth finish not only looks good but also prevents corrosion.

Common Issues in Capping

- Overlapping: Beads extending beyond the joint can create weak points.

- Undercutting: This occurs when the weld metal fails to fill the joint edges.

Root Pass vs Hot Pass vs Capping

Purpose and Functionality

Each pass has a distinct role:

- Root pass establishes the foundation.

- Hot pass reinforces the root and smooths imperfections.

- Capping seals the joint and enhances its appearance.

Techniques and Tools

Different passes require specific tools and techniques. For example, the root pass may need a higher amperage for penetration, while capping focuses on finesse and finish.

Challenges and Solutions

Common issues like slag entrapment or poor bead placement can be mitigated with proper preparation and technique.

Why Each Pass is Essential in Welding

Skipping any pass can compromise the weld’s integrity. Each layer contributes to the overall strength, durability, and aesthetic of the weld. A well-executed root pass ensures a strong foundation, the hot pass builds upon it, and capping completes the process with a protective and visually appealing layer.

FAQs

What happens if I skip a hot pass?

Skipping a hot pass can leave imperfections in the weld, compromising its strength and quality.

Can a single-pass weld replace multi-pass welding?

Single-pass welding may work for thinner materials, but multi-pass welding is essential for thicker joints.

How do I know if my root pass is good?

A good root pass shows consistent penetration and fusion without defects like gaps or burn-through.

What is the best electrode for capping?

The choice depends on the material, but low-hydrogen electrodes like E7018 are commonly used for capping.

Why is slag removal crucial in welding?

Removing slag ensures a clean surface for subsequent passes, preventing defects like slag entrapment.

Conclusion

Mastering root pass, hot pass, and capping is essential for any welder aiming for quality and precision. Each pass plays a unique role, contributing to the strength, durability, and appearance of the weld. By understanding their differences and practicing the recommended techniques, you can elevate your welding skills and achieve exceptional results.

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders