Internal Welding Defects Welding is a critical process in various industries, ensuring the structural integrity of assembled components. However, even in the hands of skilled welders, internal welding defects can compromise the quality of the welds, leading to potential hazards and failures. Introduction In the realm of welding, understanding internal …

Read More »What Causes Pinholes in Welding?

What Causes Pinholes in Welding? Introduction In the intricate world of welding, pinholes are a persistent challenge that welders encounter. These tiny voids, often invisible to the naked eye, can significantly compromise the integrity and quality of a weld. Understanding what pinholes are and why they need to be addressed …

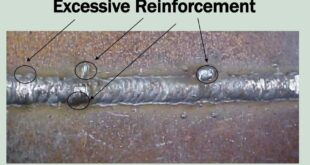

Read More »Excessive Weld Reinforcement

Excessive Weld Reinforcement Introduction Welding is a crucial process in various industries, from construction to manufacturing. It involves joining metals together using heat, pressure, or a combination of both. However, achieving the perfect weld isn’t always straightforward. One common issue that welders encounter is excessive weld reinforcement. Definition of Excessive …

Read More »Welding Cracks and How to Prevent Them

Welding Cracks and How to Prevent Them Welding is a critical process in various industries, ranging from construction to manufacturing. However, despite its importance, welding can lead to structural weaknesses if not performed correctly. One of the most common issues encountered in welding is the occurrence of cracks. These cracks …

Read More »Welding Defect Repair Guide

Art of Welding Defect Repair: A Comprehensive Guide Introduction Welding is both an art and a science, where skilled craftsmen fuse metal components to create structures of strength and integrity. However, in the intricate dance of heat and metal, imperfections can arise, jeopardizing the integrity of the weld. Understanding how …

Read More »Engineering Properties of Welds

Engineering Properties of Welds Introduction Welding is a fundamental process in the realm of engineering, serving as the bedrock for joining materials to create structures and components. It is a transformative technique that involves the melting and fusion of materials, resulting in a strong and durable bond. This introductory section …

Read More »Leak Testing for Welds

Leak Testing for Welds: Ensuring Quality and Safety Introduction In the intricate world of welding, ensuring the integrity of welds is paramount. One crucial aspect of this assurance is leak testing, a process designed to detect any imperfections or vulnerabilities in welded structures. [ads] Importance of Leak Testing Leak testing …

Read More »Weldability of Annealed, Normalized, Quenched and Tempered Materials

Weldability of Annealed, Normalized, Quenched and Tempered Materials Introduction Weldability is a crucial aspect in the realm of materials engineering and fabrication, representing the ability of a material to be welded under specific conditions without compromising its structural integrity. This property is of paramount importance in various industries, influencing the …

Read More »Planar Defects in Welding

Planar Defects in Welding: Ensuring Strong, Flawless Joints Welding is a critical process in the fabrication of various structures, and while it provides strength and durability, it’s not immune to imperfections. Planar defects in welding can compromise the integrity of joints, leading to structural issues and reduced service life. In …

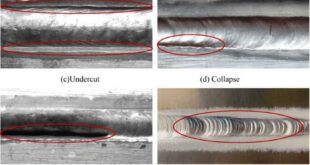

Read More »Undercut in Welding

Unveiling the Undercut in Welding Welding, a crucial industrial process, is not without its challenges. One such challenge that often goes unnoticed but can significantly compromise weld integrity is “undercut.” In this article, we’ll dive deep into the world of undercut in welding, exploring its causes, identification methods, impact on …

Read More » Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders