External Welding Defects: Ensuring Welding Excellence Welding is a fundamental process in various industries, contributing to the creation of robust structures and machinery. However, the presence of external welding defects can compromise the integrity of welded joints, leading to safety concerns and structural vulnerabilities. In this article, we explore the …

Read More »Welding of High Tensile Strength Steel

Welding of High Tensile Strength Steel Introduction Welding high tensile strength steel is a critical task in numerous industries, from construction to automotive and aerospace. These materials, known for their exceptional strength and durability, require specialized welding techniques to maintain their integrity. In this article, we’ll dive into the intricacies …

Read More »Preheating Metal Before Welding

Preheating Metal Before Welding Introduction Preheating involves heating the base metal to a specific temperature before welding. This preparatory step is often overlooked but is essential for certain materials and conditions. The brief overview of preheating in welding reveals its primary purpose: to reduce the risk of cracking, improve weld …

Read More »What Causes Pinholes in Welding?

What Causes Pinholes in Welding? Introduction In the intricate world of welding, pinholes are a persistent challenge that welders encounter. These tiny voids, often invisible to the naked eye, can significantly compromise the integrity and quality of a weld. Understanding what pinholes are and why they need to be addressed …

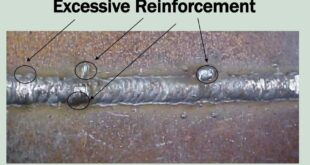

Read More »Excessive Weld Reinforcement

Excessive Weld Reinforcement Introduction Welding is a crucial process in various industries, from construction to manufacturing. It involves joining metals together using heat, pressure, or a combination of both. However, achieving the perfect weld isn’t always straightforward. One common issue that welders encounter is excessive weld reinforcement. Definition of Excessive …

Read More »Welding Burn Through

Welding Burn Through Causes & Prevention Introduction In the realm of welding, achieving strong and durable joints is paramount for ensuring the integrity and longevity of structures and components. However, despite meticulous attention to detail, welders often encounter various defects that compromise the quality of their work. One such common …

Read More »Lack of Fusion in Welded Joints

Lack of Fusion in Welded Joints Welding is a fundamental process in various industries, from construction to manufacturing. It involves joining metal pieces together using high heat to melt the base metals and then allowing them to cool and solidify, forming a strong bond. However, one of the challenges welders …

Read More »Leak Testing for Welds

Leak Testing for Welds: Ensuring Quality and Safety Introduction In the intricate world of welding, ensuring the integrity of welds is paramount. One crucial aspect of this assurance is leak testing, a process designed to detect any imperfections or vulnerabilities in welded structures. [ads] Importance of Leak Testing Leak testing …

Read More »Planar Defects in Welding

Planar Defects in Welding: Ensuring Strong, Flawless Joints Welding is a critical process in the fabrication of various structures, and while it provides strength and durability, it’s not immune to imperfections. Planar defects in welding can compromise the integrity of joints, leading to structural issues and reduced service life. In …

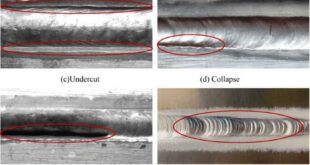

Read More »Undercut in Welding

Unveiling the Undercut in Welding Welding, a crucial industrial process, is not without its challenges. One such challenge that often goes unnoticed but can significantly compromise weld integrity is “undercut.” In this article, we’ll dive deep into the world of undercut in welding, exploring its causes, identification methods, impact on …

Read More » Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders