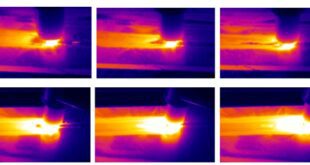

Infrared Thermography Testing – NDT Inspection Infrared Thermography Testing (IRT) is a powerful method in the realm of Non-Destructive Testing (NDT) used to evaluate materials, components, or systems without causing any damage. It’s like having X-ray vision for heat, enabling professionals to detect flaws, inconsistencies, or defects in welded joints …

Read More »Weld Defect Acceptance Criteria ASME B31.1 Power Piping

Weld Defect Acceptance Criteria ASME B31.1 Power Piping Introduction Welcome to our in-depth guide on the Weld Defect Acceptance Criteria ASME B31.1 Power Piping. In any power piping system, the quality and integrity of welds are of paramount importance to ensure safe and efficient operation. The American Society of Mechanical …

Read More » Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders