Welding Gases and Their Types Introduction Welding gases are essential components in various welding processes. They are gases or gas mixtures that create a controlled atmosphere during welding, influencing factors such as heat control, arc stability, and the overall quality of the weld. Understanding the role of welding gases is …

Read More »How to Choose the Right Welding Process for Your Project

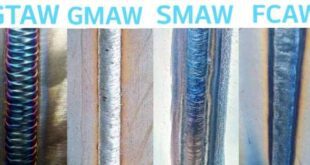

How to Choose the Right Welding Process for Your Project Introduction Selecting the appropriate welding process is a critical decision that directly affects the outcome of a welding project. With various welding techniques available, it is essential to understand the factors that influence the choice of welding process. By considering …

Read More »Ultrasonic Welding Process

Ultrasonic Welding Process Introduction Ultrasonic welding is a process used to join two or more pieces of material by applying high-frequency mechanical vibrations to the parts being joined. The process is widely used in manufacturing for joining plastics, metals, and other materials. It has become increasingly popular because it offers …

Read More »Classification of Materials Based on Composition

Classification of Materials Based on Composition Introduction: Welding is a process of joining two or more materials using heat, pressure, or a combination of both. It is an essential process in various industries, including construction, automotive, aerospace, and manufacturing. However, welding can be challenging, and selecting the right materials for …

Read More »Ferrous Vs Non-Ferrous Materials

Introduction Welding is a common industrial process that involves joining two or more materials to form a single piece. One of the most important considerations in welding is the selection of materials. Welding can be performed on a variety of materials, but they can be broadly classified into two categories …

Read More »White Metal Welding

White Metal Welding Introduction White metal welding is a specialized welding technique used to join metals with white metal alloys. It is a process where two or more metal parts are fused together using heat, pressure, and the melting of a white metal alloy. The result is a strong, durable, …

Read More »AC vs DC Welding

AC vs DC Welding Introduction Welding is a fabrication process that joins two or more pieces of metal or thermoplastics by applying heat, pressure, or both. The process involves melting the base metal or filler material to create a joint that is as strong or stronger than the original material. …

Read More »Laser Welding

Laser Welding Introduction Laser welding is a process that uses high-powered lasers to join materials together. It is a widely used technique in various industries, including aerospace, medical device manufacturing, automotive, and electronics manufacturing. Laser welding is a relatively new technology, with the first demonstration of a laser weld taking …

Read More » Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders