Optimization of Welding Process Introduction Welding process optimization refers to the systematic improvement of welding operations to enhance productivity, quality, efficiency, and cost-effectiveness. It involves analyzing various factors, such as material properties, joint design, welding parameters, and environmental conditions, to achieve optimal welding results. Optimizing welding processes is crucial for …

Read More »Keyhole Welding

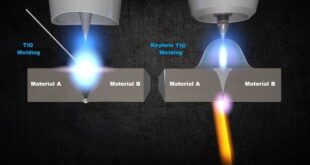

Keyhole Welding Introduction Definition and Explanation of Keyhole Welding Keyhole welding is an advanced welding technique that involves the creation of a keyhole or hole at the leading edge of the weld pool. It is achieved by using a concentrated heat source, such as a laser or an electron beam, …

Read More »How to Weld Varying Diameter Pipes

How to Weld Varying Diameter Pipes Introduction Welding varying diameter pipes can be a challenging task that requires expertise and precision. Whether you’re working on a plumbing project, industrial construction, or any other application involving pipes, understanding the proper techniques for welding different pipe diameters / pipe welding is essential. …

Read More »Welding Techniques for Thin Metal

Welding Techniques for Thin Metal Introduction Welding thin metal presents a unique set of challenges and considerations for welders. The delicate nature of thin metal requires specific techniques to ensure successful and reliable welds without distortion or burn-through. In this comprehensive guide, we will explore various welding techniques tailored for …

Read More »Welding Techniques for Steel

Welding Techniques for Steel Mastering the Art of Metal Fusion Introduction In the world of construction and manufacturing, steel is an invaluable material known for its strength and durability. To harness the full potential of steel, it is essential to understand and master the art of welding. Welding techniques for …

Read More »What is CAD Welding?

What is CAD Welding? Introduction Definition of CAD Welding CAD Welding, also known as Computer-Aided Design Welding, refers to the application of computer-aided design and manufacturing techniques in the process of welding. It involves using CAD software to create a virtual model of the welding components, simulate the welding process, …

Read More »Welding of Reactive and Refractory Metals

Welding of Reactive and Refractory Metals Introduction Definition and Significance of Welding Reactive and Refractory Metals Welding reactive and refractory metals is a crucial process in various industries, especially those that deal with extreme conditions and require materials with exceptional properties. Reactive metals, such as titanium, zirconium, and tantalum, are …

Read More »How to Choose the Right Welding Process for Your Project

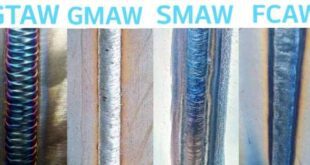

How to Choose the Right Welding Process for Your Project Introduction Selecting the appropriate welding process is a critical decision that directly affects the outcome of a welding project. With various welding techniques available, it is essential to understand the factors that influence the choice of welding process. By considering …

Read More »Self-Shielded Flux Cored Welding

Self-Shielded Flux Cored Welding Introduction Self-Shielded Flux Cored Welding is a welding process that uses a continuous, tubular electrode filled with flux to join two pieces of metal together. Unlike traditional welding methods, this process does not require an external shielding gas to protect the weld pool from atmospheric contamination. …

Read More »Classification of Materials Based on Composition

Classification of Materials Based on Composition Introduction: Welding is a process of joining two or more materials using heat, pressure, or a combination of both. It is an essential process in various industries, including construction, automotive, aerospace, and manufacturing. However, welding can be challenging, and selecting the right materials for …

Read More » Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders