Microstructural Zones of Welds: A Deep Dive Introduction In the world of metalworking and fabrication, welding is a fundamental process that joins two or more pieces of metal together. While the act of welding might seem straightforward, a closer look reveals a complex world of microstructures within the weld area. …

Read More »11 Must-Follow Rules of Welding

11 Must-Follow Rules of Welding Introduction Importance of Adhering to Safety Rules in Welding Welding is a crucial and widely used technique in various industries, including construction, manufacturing, and automotive. While welding plays a vital role in creating strong and durable connections, it also poses inherent risks and hazards. Adhering …

Read More »Welding Broken Gear Teeth

Welding Broken Gear Teeth: Restoring Functionality with Precision Introduction Welding broken gear teeth is a crucial skill in the world of machinery maintenance and repair. Whether you’re a professional welder or a DIY enthusiast, understanding how to effectively repair gear teeth can save you time and money. In this detailed …

Read More »MIG VS TIG VS Stick vs Flux Core

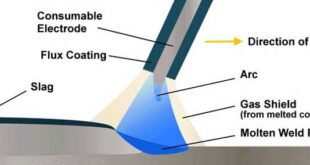

MIG VS TIG VS Stick vs Flux Core: A Comprehensive Comparison Introduction In the world of welding, there are several different processes to choose from, each with its own advantages and disadvantages. This article will explore four popular welding methods: MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), Stick, and …

Read More »Welding Torch Troubleshooting: Common Issues and Solutions

Welding Torch Troubleshooting Introduction Welding is a critical skill in various industries, from construction to manufacturing. However, even the most experienced welders can encounter issues with their welding torches. In this guide, we’ll delve into common problems welders face and provide practical solutions to address these challenges. Whether you’re a …

Read More »Underwater Welding Procedure, Working and Safety

Underwater Welding Procedure, Working and Safety Introduction Underwater welding, also known as subaqueous welding, is a specialized field that involves the use of welding techniques to join metal structures below the surface of the water. The process is used in a variety of industries such as shipbuilding and repair, offshore …

Read More »25 Common Welding Mistakes to Avoid

Common Welding Mistakes to Avoid: A Comprehensive Guide Introduction Welding is both an art and a science, and like any other skill, it requires practice and knowledge to master. While it’s natural to make mistakes when you’re starting, understanding and avoiding common welding errors can save you time, materials, and …

Read More »Bare Metal Arc Welding: Crafting Strong Bonds through Precision

Bare Metal Arc Welding: Crafting Strong Bonds through Precision Introduction In the realm of metalworking, the art of welding stands as a cornerstone technique for joining metals seamlessly. Among the myriad of welding methods available, Bare Metal Arc Welding emerges as a tried-and-true method renowned for its precision, strength, and …

Read More »Welding Non-Ferrous Metals

Welding Non-Ferrous Metals: Techniques, Applications, and Challenges Introduction Welding is a critical manufacturing process that joins materials together to create strong and durable structures. While welding is often associated with ferrous metals like steel and iron, it is equally essential for non-ferrous metals, such as aluminum, copper, and titanium. Non-ferrous …

Read More »Welding the Exotic Metals

Welding the Exotic Metals: A Comprehensive Guide Introduction Welding is a remarkable craft that has been essential in various industries, from construction to aerospace. While welding itself is an intricate skill, welding exotic metals takes it to a whole new level. In this comprehensive guide, we will delve into the …

Read More » Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders