Pressure Vessel Welding Standards Ensuring Safety and Reliability Introduction Pressure vessels play a critical role in various industries, including oil and gas, chemical, power generation, and many others. These vessels are designed to contain fluids or gases at a pressure significantly different from the ambient pressure. As such, their construction …

Read More »Standards and Requirements for Welding Fume Control

Standards and Requirements for Welding Fume Control Introduction Understanding the Importance of Welding Fume Control Welding is a common process used in various industries, but it can pose significant health risks if proper precautions are not taken. One of the major concerns in welding operations is the release of welding …

Read More »How to Choose the Right Welding Process for Your Project

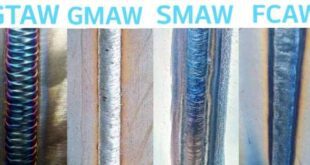

How to Choose the Right Welding Process for Your Project Introduction Selecting the appropriate welding process is a critical decision that directly affects the outcome of a welding project. With various welding techniques available, it is essential to understand the factors that influence the choice of welding process. By considering …

Read More »PPEs for Welding

PPEs for Welding Introduction Personal Protective Equipment (PPE) refers to clothing and equipment worn by individuals to protect themselves from potential workplace hazards that could cause injury or illness. In welding, PPE includes items such as gloves, helmets, face shields, aprons, and boots. The importance of PPEs in welding cannot …

Read More »Effects of Welding Variables on Welding Quality

Effects of Welding Variables on Welding Quality Introduction Welding is a process of joining two or more materials, usually metals or thermoplastics, by heating them to their melting point and then cooling them to form a permanent bond. The welding process can be performed using various methods such as gas …

Read More »Welding Inspection And Quality Control

Welding Inspection And Quality Control Introduction Welding is a process used to join materials such as metals and thermoplastics together. It is an essential technique used in many industries, including construction, automotive, and manufacturing. However, welding can be a complex process, and if not performed correctly, can result in significant …

Read More »Classification of Materials Based on Composition

Classification of Materials Based on Composition Introduction: Welding is a process of joining two or more materials using heat, pressure, or a combination of both. It is an essential process in various industries, including construction, automotive, aerospace, and manufacturing. However, welding can be challenging, and selecting the right materials for …

Read More »Ferrous Vs Non-Ferrous Materials

Introduction Welding is a common industrial process that involves joining two or more materials to form a single piece. One of the most important considerations in welding is the selection of materials. Welding can be performed on a variety of materials, but they can be broadly classified into two categories …

Read More »White Metal Welding

White Metal Welding Introduction White metal welding is a specialized welding technique used to join metals with white metal alloys. It is a process where two or more metal parts are fused together using heat, pressure, and the melting of a white metal alloy. The result is a strong, durable, …

Read More »MIG Vs MAG Welding

MIG Vs. MAG Welding Introduction Welding is a crucial process used in various industrial and manufacturing applications to join two or more metal parts. It involves heating the metal to its melting point and then fusing it together using a filler material. Among the different types of welding, MIG (Metal …

Read More » Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders