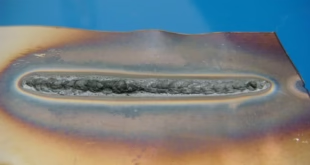

Different Types of Welding Beads What Is a Welding Bead? A welding bead is the line or deposit of metal that forms as a result of fusing two pieces of base metal during welding. It appears as a raised, visible track along the joint, and its shape, consistency, and structure …

Read More »Seal Weld

What Is a Seal Weld? What Is a Seal Weld? A seal weld is a type of weld applied primarily to prevent the passage of fluids, gases, or contaminants—not to provide structural strength. Unlike load-bearing welds, its role is sealing gaps or joints to prevent leaks, improve corrosion resistance, and …

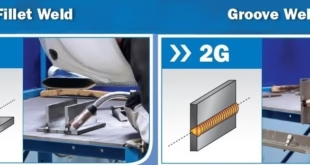

Read More »2G 2F Welding Position

2G 2F Welding Position – A Complete Guide Welding is an essential process in manufacturing, construction, and various industries. One crucial aspect of welding is understanding different welding positions, as they determine the difficulty, technique, and outcome of the weld. Among these positions, the 2G and 2F welding positions are …

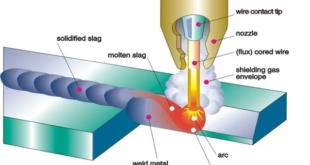

Read More »Understanding Flux Core Welding

What Is Flux Core Welding Used For? Flux core welding (FCW) has emerged as a pivotal technique in the world of fabrication due to its robustness and versatility. This article explores what flux core welding is, where it is used, and why it stands out from other welding methods. The …

Read More »Guide to Steel Grades

A Guide to Steel Grades: Low Carbon, High Carbon, and Stainless Steel Steel is one of the most versatile and widely used materials in the world, but not all steel is created equal. For welders, understanding the differences between steel grades is crucial to achieving strong, durable, and high-quality welds. …

Read More »AWS A5.1 Standard Challenges

AWS A5.1 Standard Challenges When it comes to welding, standards are the backbone of quality and safety. One such critical standard is the AWS A5.1, which governs the specifications for carbon steel electrodes used in shielded metal arc welding (SMAW). But what exactly is this standard, and why is it so …

Read More »Prevent Arc Blow

How to Prevent Arc Blow in Stick Welding Stick welding, also known as Shielded Metal Arc Welding (SMAW), is a versatile and widely used welding process. However, it comes with its own set of challenges, one of which is arc blow. If you’ve ever experienced an erratic arc, spatter, or uneven …

Read More »How to achieve Full Penetration Weld?

How to achieve Full Penetration Weld? When it comes to welding, achieving a strong, durable, and reliable bond between two materials is the ultimate goal. One of the most critical techniques to ensure this is through a full penetration weld. But what exactly does it mean, and why is it …

Read More »Sugaring In Stainless Steel

What Is Sugaring in Stainless Steel? What Does Sugaring Mean? Sugaring is a common term in welding that refers to the rough, oxidized surface that forms on stainless steel when it is exposed to oxygen during high-temperature processes, like welding. This grainy, sugar-like appearance usually forms on the underside of …

Read More »What is Narrow Gap Welding?

What is Narrow Gap Welding? Definition and Overview: Narrow gap welding (NGW) is a specialized technique tailored for welding thick materials by minimizing the width of the groove between the joint surfaces. This process significantly reduces the amount of filler material required and enhances efficiency. By creating a narrow groove, …

Read More » Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders