Can You Weld Aluminum to Steel? Exploring Compatibility and Techniques Introduction Welding is a crucial process in the world of metal fabrication, allowing the joining of different metals for various applications. One intriguing question that often arises is, “Can you weld aluminum to steel?” This article delves into the compatibility …

Read More »Heavy Equipment Welding and Fabrication

Heavy Equipment Welding and Fabrication In construction, Heavy Equipment Welding and Fabrication stand as the pillars of strength, quite literally. The process involves melding metals together to create structures that can withstand the test of time and the rigors of demanding projects. In this comprehensive guide, we delve into the …

Read More »Welding Box Section Square Tube at 90-Degree Corners

How to Weld Box Section Square Tube at 90-Degree Corners Introduction In the world of metal fabrication and construction, welding stands as the transformative force that melds raw materials into intricate structures of both form and function. The skill of a welder can shape the skyline of a city, build …

Read More »Welding in Automobile Sector

Welding in Automobile Sector: Enhancing Structural Integrity and Safety Introduction In the dynamic world of automotive manufacturing, welding plays a crucial role in ensuring the structural integrity, safety, and overall performance of vehicles. The welding process binds various components together, creating a cohesive unit that can withstand the demands of …

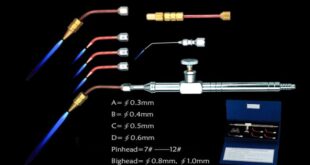

Read More »What is Oxy-Hydrogen Welding?

Oxy-Hydrogen Welding Introduction In the realm of modern manufacturing, technological advancements are continually reshaping the way we create, build, and innovate. Oxy-Hydrogen Welding, a cutting-edge technique that combines oxygen and hydrogen gases, has emerged as a revolutionary method of joining materials. This article delves deep into the world of Oxy-Hydrogen …

Read More »What Is Autogenous Welding?

What Is Autogenous Welding? Introduction Autogenous welding is a specialized technique of welding that holds notable importance in various industrial applications. At its core, autogenous welding involves fusing two metal pieces together using heat, without the need for any additional filler material. This unique approach has garnered attention within the …

Read More »Essential Welding Equipment And Tools

Essential Welding Equipment And Tools Introduction Welding is a fundamental process used in the manufacturing, construction, and repair of metal structures and equipment. It involves heating two metal parts to their melting points and joining them together by melting a filler metal into the joint. Welding is a highly specialized …

Read More »Twin Carbon Arc Welding Unleashing Precision and Power

Twin Carbon Arc Welding: Unleashing Precision and Power Introduction Welcome to the realm of Twin Carbon Arc Welding, a revolutionary welding technique that has taken the metalworking industry by storm. In this article, we will delve into the intricate details of Twin Carbon Arc Welding, exploring its features, applications, advantages, …

Read More »Vertical Welding Vs. Horizontal Welding

Vertical Welding Vs. Horizontal Welding Introduction Welding stands as a cornerstone of modern fabrication, enabling the transformation of raw materials into intricate structures and products. Within the realm of welding, the orientation in which the process is conducted holds significant sway over the outcome. Vertical welding and horizontal welding, two …

Read More »What Is Air Acetylene Welding?

What Is Air Acetylene Welding? Introduction Definition of Air Acetylene Welding Air Acetylene Welding is a welding process that utilizes a mixture of acetylene gas and atmospheric air as the fuel to generate a high-temperature flame. This flame is used to melt and join metals or other materials together, creating …

Read More » Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders