Pulse MIG Welding

Introduction

Pulse MIG Welding, also known as Pulsed Gas Metal Arc Welding (GMAW-P), is an advanced welding process that involves the intermittent pulsing of current through the welding wire. Unlike conventional MIG (Metal Inert Gas) welding, where a constant voltage and current are applied, Pulse MIG Welding alternates between high peak current levels and low background current levels. This pulsing action enables better control over heat input, deposition rates, and weld penetration, resulting in precise, high-quality welds.

Understanding Pulse MIG Welding

Pulse MIG Welding, characterized by its intermittent current pulsing, operates on distinct principles and mechanics that set it apart from conventional MIG welding methods. This section aims to elucidate the fundamental aspects of Pulse MIG Welding, compare it to traditional MIG welding, and explain how pulse modulation enhances control and precision in the welding process.

Basic Principles and Mechanics

At its core, Pulse MIG Welding functions by alternating between two main current levels during the welding process: peak current and background current. The peak current, also known as the pulse current, generates the necessary heat for melting the base metal and welding wire, while the background current maintains the arc stability and allows for controlled cooling of the weld pool between pulses.

This cyclic pulsing of current enables finer control over the weld bead formation, deposition rate, and heat input into the base material. By adjusting parameters such as pulse frequency, pulse width, and peak current amplitude, welders can tailor the welding process to suit specific materials, thicknesses, and joint configurations, thereby achieving optimal weld quality and performance.

Comparison with Traditional MIG Welding

In contrast to Pulse MIG Welding, traditional MIG welding employs a continuous current flow with a constant voltage and wire feed speed. While conventional MIG welding offers simplicity and ease of operation, it may lack the precision and control provided by pulse modulation.

One significant advantage of Pulse MIG Welding over traditional MIG welding is its ability to reduce heat input and minimize distortion, especially when welding thin materials or heat-sensitive alloys. Additionally, Pulse MIG Welding can produce aesthetically pleasing welds with minimal spatter, making it ideal for applications where cosmetic appearance is crucial.

How Pulse Modulation Enhances Control and Precision

Pulse modulation plays a pivotal role in enhancing control and precision during the welding process. By adjusting the pulse parameters, welders can effectively manage heat input, control penetration depth, and optimize weld bead shape. This level of control is particularly beneficial when welding materials of varying thicknesses or when dealing with complex joint geometries.

Moreover, pulse modulation allows for improved arc stability and better control over droplet transfer, resulting in smoother, more stable arcs and reduced instances of arc wandering or spatter. The ability to fine-tune pulse parameters enables welders to achieve consistent weld quality across different welding positions and joint configurations, ultimately leading to superior overall welding performance.

Techniques for Successful Pulse MIG Welding

Achieving optimal results with Pulse MIG Welding requires a combination of proper equipment setup, parameter adjustment, knowledge of welding techniques, and troubleshooting skills. This section explores key techniques essential for successful Pulse MIG Welding, including equipment setup, parameter adjustment, welding positions, techniques for different materials, and troubleshooting common issues.

Setting up the Equipment

Before initiating Pulse MIG Welding, it’s crucial to ensure that the welding equipment is properly set up and calibrated. This includes:

- Selecting the appropriate welding machine: Choose a MIG welding machine capable of pulse welding and ensure it’s compatible with the materials and thicknesses you intend to weld.

- Preparing the welding gun and wire feeder: Ensure the welding gun and wire feeder are in good condition, with clean contact tips and properly aligned components.

- Securing the shielding gas: Use the appropriate shielding gas for the specific material being welded, and ensure the gas flow rate is set according to manufacturer recommendations.

- Checking power source settings: Verify that the power source settings, including voltage and current, are adjusted to the recommended levels for Pulse MIG Welding.

Adjusting Parameters: Voltage, Wire Feed Speed, Pulse Frequency, etc.

Fine-tuning welding parameters is essential for achieving optimal weld quality and performance. Key parameters to adjust include:

- Voltage: Adjust voltage to control arc length and penetration depth. Higher voltage settings generally result in deeper penetration.

- Wire Feed Speed: Modify wire feed speed to regulate deposition rate and weld bead size. Higher wire feed speeds typically produce larger weld beads.

- Pulse Frequency: Adjust pulse frequency to control the number of pulses per second. Higher frequencies are often used for thinner materials or when welding in challenging positions.

- Pulse Width: Alter pulse width to regulate heat input and bead profile. Narrower pulse widths are suitable for thin materials, while wider pulse widths provide better fusion for thicker sections.

Welding Positions and Techniques for Different Materials

Different welding positions and techniques may be required based on the material being welded and the specific joint configuration. Some considerations include:

- Joint Preparation: Ensure proper joint fit-up and cleanliness to promote good weld penetration and fusion.

- Welding Positions: Practice welding in various positions, including flat, horizontal, vertical, and overhead, to master technique and ensure consistent weld quality.

- Material Selection: Understand the characteristics of the materials being welded and adjust welding parameters accordingly. Pulse MIG Welding is suitable for a wide range of materials, including carbon steel, stainless steel, aluminum, and alloys.

Troubleshooting Common Issues

Even with proper setup and parameter adjustment, welders may encounter common issues during Pulse MIG Welding. Some troubleshooting tips include:

- Addressing Spatter: Adjusting parameters such as wire feed speed and pulse frequency can help minimize spatter. Ensuring proper shielding gas coverage and using anti-spatter agents may also mitigate spatter.

- Dealing with Burn-Through: Reduce heat input by lowering voltage or increasing travel speed to prevent burn-through, especially when welding thin materials.

- Handling Porosity: Ensure proper gas coverage and clean base metal surfaces to prevent porosity. Adjusting gas flow rate and electrode extension can also help minimize porosity issues.

Benefits of Pulse MIG Welding

Pulse MIG Welding offers a multitude of advantages over traditional welding methods, making it a preferred choice for many welding applications. This section explores the key benefits of Pulse MIG Welding, including improved weld quality and aesthetics, increased productivity and efficiency, minimized distortion and spatter, and reduced heat input and distortion.

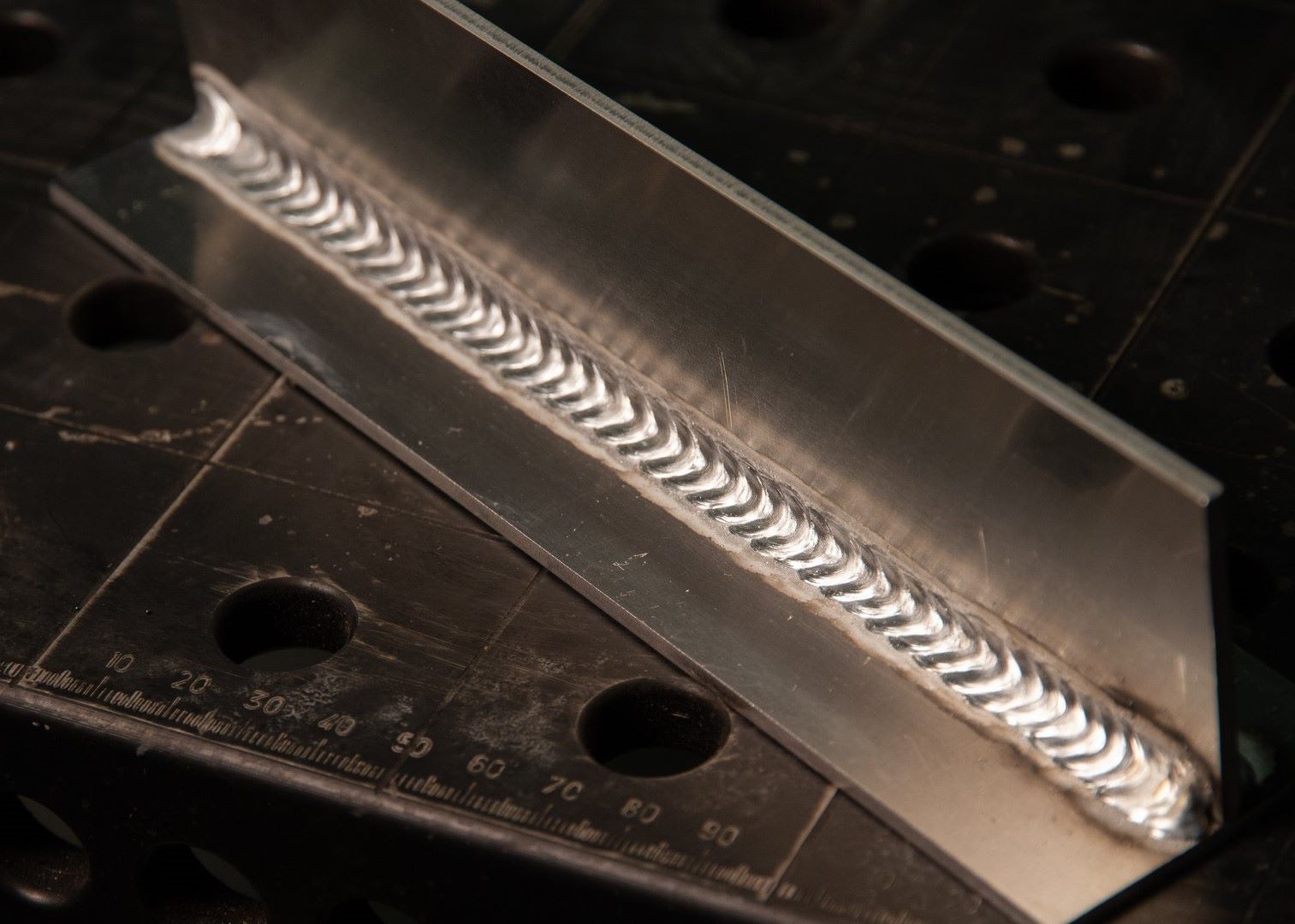

Improved Weld Quality and Aesthetics

One of the primary benefits of Pulse MIG Welding is its ability to produce high-quality welds with superior aesthetics. The intermittent pulsing of current allows for better control over the weld pool, resulting in smoother bead profiles, reduced weld spatter, and improved fusion between the base metal and filler material. This precision and control lead to visually appealing welds with minimal defects, enhancing the overall appearance and quality of the welded joint.

Increased Productivity and Efficiency

Pulse MIG Welding offers increased productivity and efficiency compared to traditional welding methods. The precise control over welding parameters, such as pulse frequency and peak current, allows for faster travel speeds and higher deposition rates while maintaining weld quality. Additionally, Pulse MIG Welding typically requires less post-weld cleanup due to reduced spatter and distortion, further improving overall efficiency and reducing downtime.

Minimized Distortion and Spatter

Distortion and spatter are common challenges in welding, often leading to rework and additional costs. Pulse MIG Welding helps mitigate these issues by providing better control over heat input and weld bead formation. The intermittent pulsing of current results in reduced overall heat input into the base metal, minimizing distortion and distortion-related defects. Additionally, the controlled droplet transfer during pulsing reduces spatter formation, resulting in cleaner welds and less post-weld cleanup.

Reduced Heat Input and Distortion

One of the key advantages of Pulse MIG Welding is its ability to reduce heat input and distortion compared to traditional welding methods. By pulsing the current on and off, Pulse MIG Welding effectively distributes heat throughout the weld zone, allowing for greater control over the welding process. This controlled heat input helps prevent overheating of the base metal and minimizes distortion, particularly in thin materials or heat-sensitive alloys. As a result, Pulse MIG Welding enables the welding of complex geometries and thin sections with minimal risk of distortion or warping.

Applications of Pulse MIG Welding

Pulse MIG Welding has found widespread application across various industries due to its versatility, precision, and efficiency. This section explores some key industries where Pulse MIG Welding is commonly utilized, including the automotive industry, aerospace sector, construction sector, and general manufacturing.

Automotive Industry: Chassis, Bodywork, and Components

In the automotive industry, Pulse MIG Welding plays a crucial role in the fabrication of chassis, bodywork, and various components. Its ability to produce high-quality welds with minimal distortion and spatter makes it well-suited for joining automotive steel, aluminum, and alloy materials. Pulse MIG Welding is used in the production of vehicle frames, body panels, exhaust systems, and structural components, contributing to the strength, durability, and aesthetics of automobiles.

Aerospace: Aluminum and Stainless Steel Fabrication

Pulse MIG Welding is extensively used in the aerospace sector for the fabrication of aluminum and stainless steel components. Its precise control over heat input and weld bead formation makes it ideal for welding thin-gauge materials commonly found in aircraft structures and assemblies. Pulse MIG Welding is employed in the manufacture of fuselage panels, wing structures, engine components, and other critical aerospace parts, ensuring the integrity and reliability of aircraft systems.

Construction: Structural Steel, Pipelines, and Fabrication

In the construction industry, Pulse MIG Welding is employed for a wide range of applications, including structural steel fabrication, pipeline construction, and general fabrication work. Its ability to weld a variety of materials, including carbon steel, stainless steel, and aluminum, makes it indispensable for joining structural members, beams, columns, and other building components. Pulse MIG Welding is also utilized in the construction of pipelines for transporting fluids and gases, ensuring strong, leak-free joints that withstand environmental stresses and pressures.

General Manufacturing: Sheet Metal, Fabrication, and Repairs

Pulse MIG Welding finds extensive use in general manufacturing processes, including sheet metal fabrication, assembly, and repairs. Its versatility and adaptability make it suitable for welding a wide range of materials and thicknesses commonly used in manufacturing operations. Pulse MIG Welding is employed in the production of appliances, machinery, furniture, and other consumer goods, as well as in the repair and maintenance of industrial equipment and components. Its ability to produce clean, aesthetically pleasing welds with minimal distortion makes it a preferred choice for manufacturing applications where appearance and precision are paramount.

FAQs

Is pulse MIG welding suitable for all types of metals?

Pulse MIG welding can be used with various metals, including steel, aluminum, and stainless steel, but the suitability depends on factors such as material thickness and joint configuration.

What are the main advantages of pulse MIG welding over traditional MIG welding?

Pulse MIG welding offers superior weld quality, reduced heat input, minimized spatter and distortion, and increased productivity compared to traditional MIG welding methods.

Does pulse MIG welding require specialized equipment?

Yes, pulse MIG welding typically requires specialized welding equipment capable of delivering the pulsing current and adjusting parameters such as pulse frequency and amplitude.

Is pulse MIG welding difficult to learn?

While pulse MIG welding may require additional training and experience compared to traditional MIG welding, with proper instruction and practice, welders can master the technique and achieve excellent results.

What are the key factors to consider when choosing between pulse MIG welding and traditional MIG welding?

When deciding between pulse MIG welding and traditional MIG welding, factors such as project requirements, material type and thickness, budget, and desired weld quality should be taken into account.

Conclusion

Pulse MIG welding represents a significant advancement in welding technology, offering unparalleled precision, efficiency, and weld quality. By understanding its principles and applications, welders can harness the full potential of this transformative technique to meet the demands of modern manufacturing and construction industries.

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders