Exploring Types of Welding Defects

Welding defects are imperfections in the weld joint that compromise the structural integrity, appearance, and functionality of the weld. These defects can occur due to various factors, including improper welding techniques, unsuitable materials, or environmental influences. Understanding the different types of welding defects, their causes, and prevention techniques is essential for ensuring high-quality welds and maintaining safety standards. In this comprehensive guide, we’ll explore the various types of welding defects, how they affect the weld joint, and effective ways to prevent and repair these issues.

Understanding Welding Defects: Definition and Classification

Welding defects are classified based on their location, nature, and visibility. They can be categorized into several groups:

- External Defects:

- Found on the surface of the weld and visible to the naked eye.

- Examples include cracks, porosity, and undercut.

- Internal Defects:

- Occur inside the weld and are not visible without specialized inspection methods.

- Examples include slag inclusions and lack of fusion.

- Dimensional Defects:

- Affect the size and shape of the weld or the welded structure.

- Examples include excess weld metal or misalignment.

Each type of defect has its specific causes, and identifying the root cause is the first step in determining the appropriate corrective action.

Common Types of Welding Defects and Their Causes

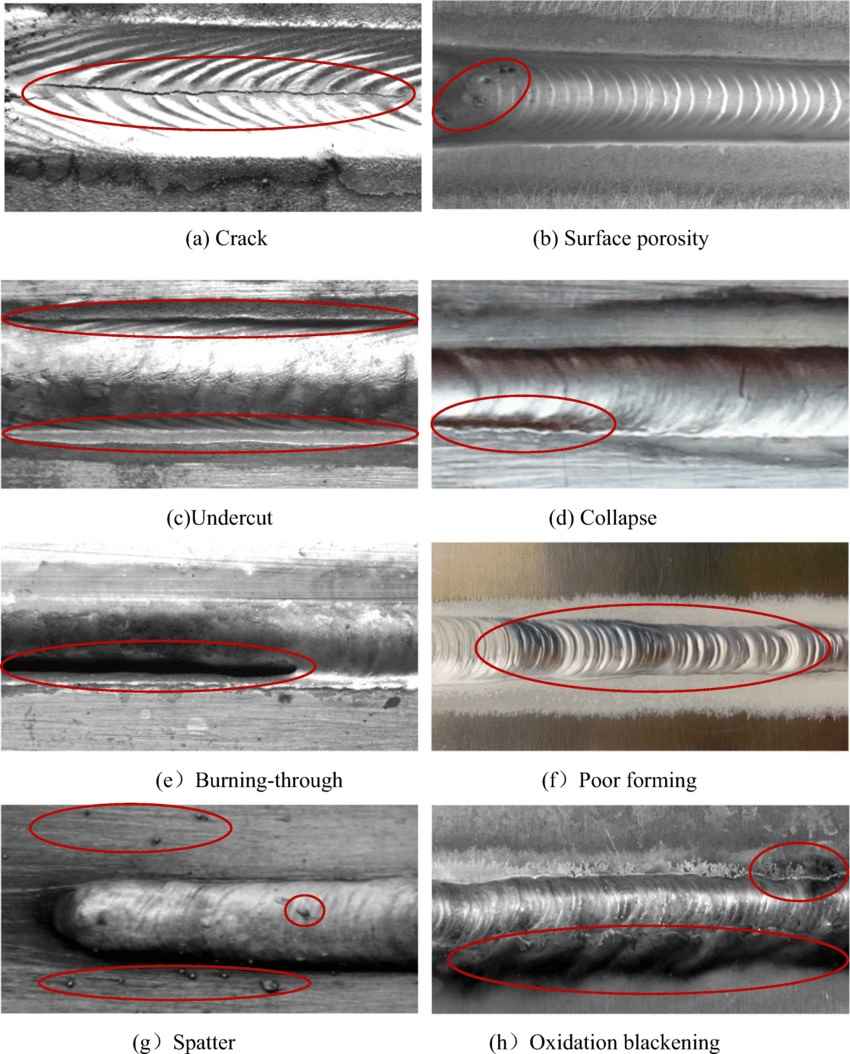

- Cracks

- Description: Cracks are separations or fractures in the weld metal or adjacent base metal. They can appear on the surface, within the weld, or in the heat-affected zone (HAZ).

- Types: Hot cracks (occur during solidification), cold cracks (appear after cooling), and crater cracks (form at the end of a weld).

- Causes: High residual stress, improper cooling, contamination, or excessive heat input.

- Prevention: Use preheating and controlled cooling techniques, reduce residual stress by adjusting weld parameters, and ensure the cleanliness of the base and filler materials.

- Porosity

- Description: Porosity is the presence of small cavities or pores in the weld caused by trapped gas.

- Types: Surface porosity (visible on the weld surface) and subsurface porosity (beneath the surface).

- Causes: Contaminated base or filler material, moisture, incorrect shielding gas, or excessive welding speed.

- Prevention: Use clean, dry materials, maintain proper shielding gas flow, and control the welding speed to allow trapped gas to escape.

- Undercut

- Description: An undercut is a groove that forms at the weld toe, reducing the thickness of the base metal and compromising joint strength.

- Causes: Excessive heat input, high welding speed, improper torch angle, or incorrect electrode size.

- Prevention: Use the correct welding parameters, reduce welding speed, and adjust the torch angle for better control.

- Lack of Fusion

- Description: Lack of fusion occurs when the weld metal does not properly fuse with the base metal or the preceding weld bead.

- Causes: Insufficient heat input, incorrect electrode angle, contaminated base metal, or improper joint preparation.

- Prevention: Increase heat input, clean the base metal, and ensure proper electrode angle and joint fit-up.

- Slag Inclusions

- Description: Slag inclusions are non-metallic particles trapped inside the weld, usually resulting from improper slag removal between weld passes.

- Causes: Poor slag removal, improper electrode manipulation, or incorrect weld bead placement.

- Prevention: Clean slag between passes, use correct electrode angles, and avoid rapid cooling.

- Incomplete Penetration

- Description: Incomplete penetration occurs when the weld metal does not fully penetrate the joint thickness.

- Causes: Low heat input, incorrect joint design, or improper welding speed.

- Prevention: Increase heat input, use a proper joint design, and control the travel speed.

- Excessive Spatter

- Description: Spatter consists of small droplets of molten metal that are ejected from the weld and stick to the surrounding area.

- Causes: High welding current, incorrect arc length, or contamination.

- Prevention: Use proper welding parameters, maintain correct arc length, and keep materials clean.

- Burn-Through

- Description: Burn-through occurs when the weld metal melts completely through the base material, creating a hole.

- Causes: Excessive heat input, thin base material, or incorrect electrode size.

- Prevention: Use lower heat input, appropriate electrode size, and control travel speed.

Techniques for Correcting Welding Defects

Identifying a welding defect is only the first step. Corrective techniques are crucial for restoring the integrity and quality of the weld.

- Crack Repair:

- Method: Remove the cracked section by grinding or gouging, and re-weld using controlled heat input.

- Tip: Preheat and post-heat as needed to minimize residual stresses.

- Porosity Removal:

- Method: Remove the affected area by grinding, clean the joint thoroughly, and re-weld using proper shielding gas.

- Tip: Check for any contamination in the base and filler materials before re-welding.

- Undercut Correction:

- Method: Fill the groove with additional weld passes using lower heat input and reduced speed.

- Tip: Control torch angle and travel speed to prevent further undercutting.

- Lack of Fusion Repair:

- Method: Remove the defective section, ensure proper joint fit-up, and re-weld with increased heat input.

- Tip: Maintain a consistent electrode angle for better fusion.

- Slag Inclusion Removal:

- Method: Remove slag mechanically, grind the weld bead if necessary, and re-weld.

- Tip: Clean the weld thoroughly between passes and use proper electrode manipulation.

- Incomplete Penetration Repair:

- Method: Grind the weld to access the root, adjust the joint design, and re-weld with higher heat input.

- Tip: Use back-gouging or back-welding techniques to ensure full penetration.

- Spatter Removal:

- Method: Use a chipping hammer or grinder to remove spatter and smoothen the surface.

- Tip: Adjust welding parameters to reduce spatter formation.

- Burn-Through Repair:

- Method: Reduce heat input and re-weld using a proper electrode size. Fill the burn-through hole with multiple passes if necessary.

- Tip: Control heat input and travel speed to prevent recurrence.

Tips for Preventing Welding Defects

- Proper Joint Preparation:

Ensure the joint is clean, free of contaminants, and properly aligned before starting the weld. - Control of Welding Parameters:

Use the recommended voltage, current, and travel speed for the specific welding process and material. - Use Appropriate Filler Material:

Match the filler material to the base metal properties to ensure compatibility and reduce defects. - Maintain Correct Electrode Angle:

Use a consistent electrode angle to control penetration, fusion, and bead shape. - Implement Preheating and Post-Welding Procedures:

Use preheating and post-welding treatments to control residual stress and prevent cracking. - Regularly Inspect Equipment:

Ensure that the welding machine, torch, and other equipment are in good condition and functioning correctly.

Conclusion

Welding defects are a common challenge that can significantly impact the quality and performance of a weld joint. Understanding the types of defects, their causes, and effective prevention methods is essential for producing high-quality welds. By implementing proper welding techniques, controlling welding parameters, and performing thorough inspections, welders can minimize the occurrence of defects and maintain the structural integrity of their projects. Whether you’re a novice welder or an experienced professional, mastering the art of defect-free welding is crucial for delivering safe and reliable welds.

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders