What Is Sugaring in Stainless Steel?

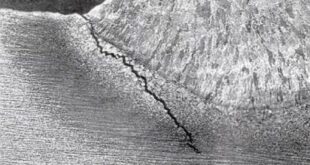

What Does Sugaring Mean? Sugaring is a common term in welding that refers to the rough, oxidized surface that forms on stainless steel when it is exposed to oxygen during high-temperature processes, like welding. This grainy, sugar-like appearance usually forms on the underside of the weld, where shielding gas may not have been applied effectively.

Why Does It Matter? Sugaring isn’t just a cosmetic issue; it can weaken the material’s integrity and reduce its corrosion resistance. If left unchecked, it can lead to failures in applications where stainless steel is expected to be robust and durable.

Image credit:millerwelds.com

How Sugaring Happens

The Process Behind Sugaring Sugaring occurs when stainless steel is exposed to oxygen at elevated temperatures. During welding, the chromium in stainless steel combines with oxygen, forming chromium oxides. These oxides appear as a rough, dark surface, which disrupts the smooth finish and compromises the material’s strength.

Factors Contributing to Sugaring

Oxygen Exposure Oxygen is the primary culprit. When the molten metal is exposed to air, the high heat promotes rapid oxidation, especially in the absence of adequate shielding gas.

High Temperatures The higher the temperature during welding, the more likely sugaring is to occur. Excessive heat increases the rate of oxidation, making it crucial to manage heat input effectively.

Common Causes of Sugaring in Stainless Steel

Improper Welding Techniques Incorrect welding methods, such as excessive heat or poor technique, can leave the underside of the weld vulnerable to oxidation.

Lack of Shielding Gas Shielding gases like argon or helium create a protective barrier against oxygen. Without sufficient shielding gas coverage, oxidation is inevitable.

Poor Material Preparation Failing to clean the material properly before welding can introduce contaminants, exacerbating sugaring.

How Sugaring Affects Stainless Steel

Structural Implications Sugaring compromises the structural integrity of stainless steel. The oxidized surface can lead to weak spots, increasing the risk of cracks or fractures over time.

Aesthetic Damage Besides weakening the material, sugaring tarnishes its appearance. Stainless steel is often chosen for its polished finish, and sugaring disrupts this look, making it less appealing for decorative or visible applications.

Preventing Sugaring During Welding

Use of Shielding Gas The most effective way to prevent sugaring is by ensuring consistent coverage of shielding gas. Use a high-quality gas like argon or a mixture of argon and helium to protect the weld from oxygen exposure.

Proper Welding Techniques

Controlling Heat Input Use the lowest possible heat setting that achieves a solid weld. Excessive heat increases the chances of oxidation.

Back Purging Back purging involves introducing shielding gas to the backside of the weld. This creates an oxygen-free environment on both sides, reducing the likelihood of sugaring.

Material Preparation Best Practices Thoroughly clean the surface of the stainless steel before welding. Remove any grease, oil, or dirt that could interfere with the welding process.

Tools and Equipment to Prevent Sugaring

Importance of Quality Welding Equipment Invest in high-quality welding machines and torches to achieve precise control over heat and shielding gas application.

Role of Purge Dams and Tapes Purge dams and tapes are used to contain the shielding gas in the weld area. They are especially useful for complex welds where back purging is challenging.

Benefits of Preventing Sugaring

Enhanced Durability Preventing sugaring ensures the material retains its strength and corrosion resistance, prolonging its lifespan.

Improved Aesthetic Appeal A smooth, polished finish enhances the visual appeal of stainless steel, making it suitable for both functional and decorative uses.

Cost Savings Avoiding sugaring reduces the need for costly repairs or replacements, saving both time and money in the long run.

Case Studies and Examples

Real-Life Instances of Sugaring Issues In industrial settings, poorly executed welds have led to structural failures and costly downtime. These cases highlight the importance of proper technique.

Success Stories in Prevention Welders who adopt best practices, such as using high-quality shielding gas and back purging, report significantly better outcomes with minimal sugaring.

FAQs

What is the main cause of sugaring in stainless steel?

Sugaring is primarily caused by oxygen exposure during welding, especially when proper shielding gas or back purging is not used.

How can shielding gas prevent sugaring?

Shielding gas creates a protective barrier around the weld, preventing oxygen from oxidizing the stainless steel at high temperatures.

What are the risks of neglecting sugaring?

Neglecting sugaring can lead to weakened welds, increased corrosion, and reduced material lifespan.

Can sugaring be reversed or fixed?

While minor sugaring can sometimes be polished or cleaned, severe cases may require re-welding or replacement of the affected material.

What tools are essential to prevent sugaring?

High-quality welding machines, shielding gases, purge dams, and proper cleaning tools are essential for preventing sugaring.

Conclusion

Sugaring in stainless steel is a preventable issue that, when addressed correctly, ensures the material’s strength, appearance, and durability. By understanding the causes and implementing proper welding techniques, you can avoid the pitfalls of oxidation and create high-quality welds that stand the test of time.

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders