The Role and Duties of a Welding Inspector In the welding industry, structural integrity and safety hinge on more than just skilled welders and advanced equipment — they depend significantly on the vigilance and expertise of welding inspectors. These professionals are the backbone of welding quality assurance, tasked with ensuring …

Read More »Infrared Thermography Testing

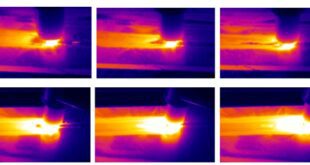

Infrared Thermography Testing – NDT Inspection Infrared Thermography Testing (IRT) is a powerful method in the realm of Non-Destructive Testing (NDT) used to evaluate materials, components, or systems without causing any damage. It’s like having X-ray vision for heat, enabling professionals to detect flaws, inconsistencies, or defects in welded joints …

Read More »Leak Testing for Welds

Leak Testing for Welds: Ensuring Quality and Safety Introduction In the intricate world of welding, ensuring the integrity of welds is paramount. One crucial aspect of this assurance is leak testing, a process designed to detect any imperfections or vulnerabilities in welded structures. [ads] Importance of Leak Testing Leak testing …

Read More »Neutron Radiography Testing – NDT Inspection

Neutron Radiography Testing: Unveiling the Invisible Neutron radiography testing, a powerful and non-destructive imaging technique, has become indispensable in various industries. From ensuring the structural integrity of aerospace components to revolutionizing medical diagnostics, neutron radiography has carved a niche for itself in the realm of scientific innovation. How Neutron Radiography …

Read More »Thermographic Testing – NDT Inspection

Maximizing Quality: Comprehensive Guide Thermographic Testing for Welded Joints Thermographic Testing operates on the principle of detecting temperature variations. It utilizes an infrared camera to capture the heat patterns emitted by the surface of the welded joint. The underlying idea is simple: flaws or defects often generate distinct thermal signatures. …

Read More »Visual Inspection for Welding – Ensuring Quality and Integrity

Visual Inspection for Welding Welding plays a pivotal role in industries ranging from construction to manufacturing, creating strong and durable joints that are crucial for the integrity of structures and products. Ensuring the quality of these welds is paramount, and one of the most fundamental methods to achieve this is …

Read More »Ultrasonic Testing – NDT Inspection

Ultrasonic Testing – NDT Inspection Introduction Ultrasonic Testing (UT) is a non-destructive testing (NDT) technique widely used in the field of welding inspection. It involves the use of high-frequency sound waves to detect and evaluate defects in welds without causing any damage to the tested material. In the world of …

Read More »Radiography Testing (RT)- NDT Inspection

Radiography Testing (RT)- NDT Inspection Introduction Radiography Testing (RT) is a non-destructive testing (NDT) method used in welding to inspect and evaluate the quality of welds. It involves the use of X-rays or gamma rays to create images of the internal structure of the welded components. The purpose of this …

Read More »Introduction to Destructive Weld Testing

Introduction to Destructive Weld Testing: Ensuring Strong and Reliable Joints Introduction Welding is a vital process in various industries, from construction and manufacturing to automotive and aerospace. The quality and reliability of welded joints play a crucial role in ensuring the structural integrity and safety of the finished product. To …

Read More »Penetrant Testing (PT) – NDT Inspection

Penetrant Testing (PT) – NDT Inspection Introduction Welcome to this comprehensive guide on Penetrant Testing (PT) – NDT Inspection. In this article, we will explore the various aspects of PT, its applications, techniques, inspection methods, advantages, limitations, and more. Whether you are new to the field or seeking to expand …

Read More » Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders