Cavitation in Centrifugal Pumps: Causes, Effects, and Prevention

Centrifugal pumps are the workhorses of modern industry, responsible for moving liquids in sectors ranging from power generation and oil refining to chemical processing and water supply. Despite their robust design, one of the most destructive phenomena they face is cavitation — a silent enemy that can rapidly erode metal, reduce efficiency, and bring a pumping system to a standstill.

Understanding cavitation is not just about maintaining equipment — it’s about ensuring system reliability, energy efficiency, and operational safety. In many plants, undetected cavitation is responsible for unplanned shutdowns and costly repairs. Therefore, recognizing its causes, effects, and prevention strategies is vital for every engineer and maintenance professional.

Working Principle of Centrifugal Pumps

Main Components

A centrifugal pump consists of several key elements: an impeller, casing, shaft, bearings, and mechanical seal. The impeller is the heart of the pump — it rotates rapidly, imparting velocity and pressure to the liquid. The casing converts this kinetic energy into pressure energy, guiding the flow toward the discharge nozzle.

Flow Path and Energy Conversion

When the impeller rotates, it draws liquid into its center (the eye) and accelerates it outward by centrifugal force. This motion converts mechanical energy from the motor into hydraulic energy in the fluid. The casing’s design ensures efficient conversion and minimizes losses.

Visual Analogy

Imagine water swirling in a bucket — the faster you spin, the higher the water climbs along the walls due to centrifugal force. Similarly, in a centrifugal pump, this motion creates a pressure differential, allowing the fluid to move continuously from suction to discharge.

Types of Centrifugal Pumps

Based on Stages

Single-stage pumps: Have one impeller; ideal for low to medium head applications.

Multi-stage pumps: Contain multiple impellers for higher heads, common in boiler feedwater systems.

Based on Orientation

Horizontal pumps: Easy to maintain and widely used in industrial plants.

Vertical pumps: Space-saving and suited for deep well or sump applications.

Based on Function

Self-priming pumps handle air-liquid mixtures.

Submersible pumps operate entirely underwater.

Slurry pumps handle abrasive or particle-laden fluids.

What Is Cavitation?

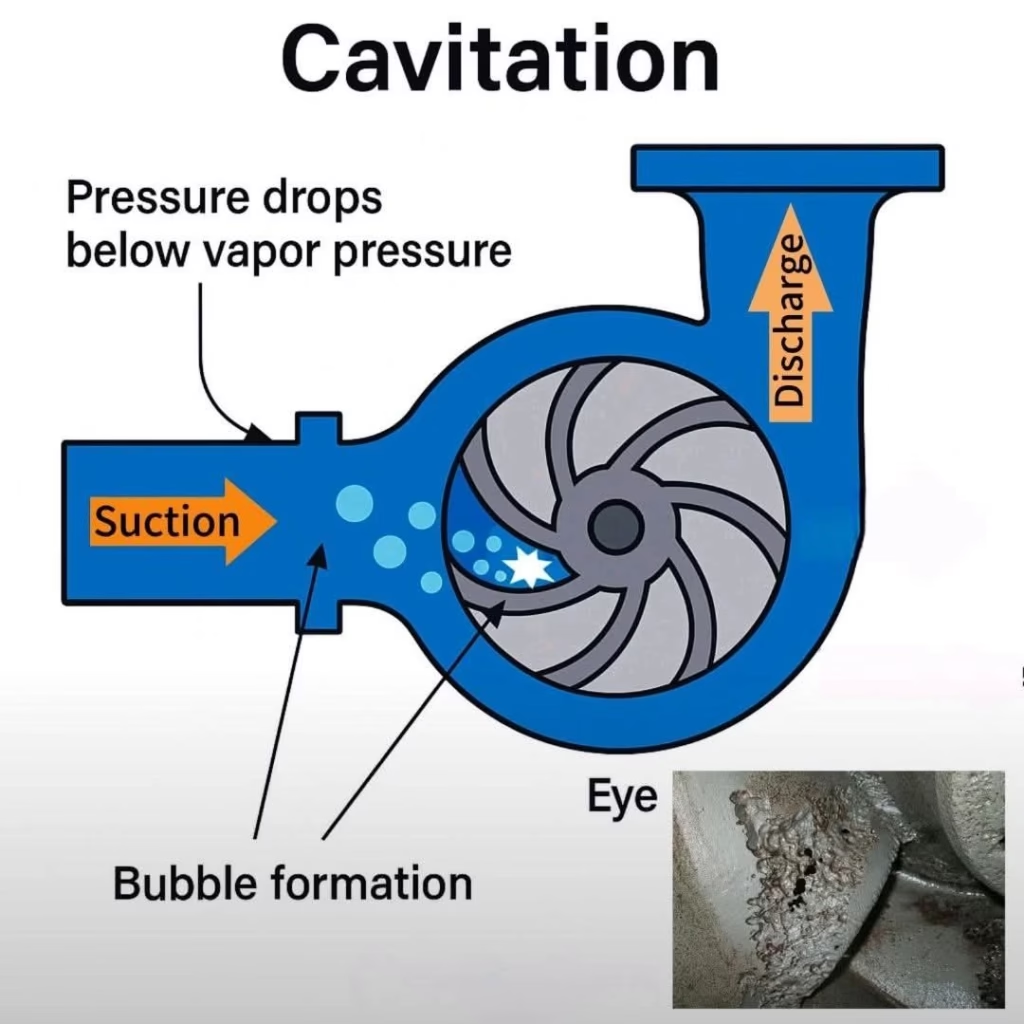

Definition of Cavitation

Cavitation is the formation and violent collapse of vapor bubbles within a liquid, caused when local pressure drops below the liquid’s vapor pressure. These tiny vapor pockets collapse as they move into higher-pressure regions, releasing intense shockwaves.

The Physics Behind Cavitation

When the pressure in a pump’s suction or impeller eye falls too low, liquid begins to vaporize. These vapor bubbles travel through the impeller and suddenly collapse when pressure recovers. The implosion of these bubbles can generate micro-jets strong enough to pit metal surfaces.

Conditions That Cause Cavitation

Cavitation occurs when:

Suction pressure is insufficient

Fluid temperature is high

Flow velocity increases abnormally, reducing local pressure

This is a balance issue between NPSH available (NPSHa) and NPSH required (NPSHr) by the pump.

Causes of Cavitation

Low Suction Pressure

When the suction line experiences restrictions, elevation, or long piping runs, pressure at the pump inlet drops — making vapor formation likely.

High Fluid Temperature

Warm liquids have a lower vapor pressure, meaning they vaporize easily. This is why hot water systems or condensate pumps are more prone to cavitation.

Poor Pump Installation or Design Flaws

Improperly sized suction lines, sharp elbows, or undersized valves before the pump can cause turbulence and reduce NPSH.

Inadequate NPSH

If NPSHa < NPSHr, the pump will cavitate. This mismatch is one of the primary technical causes of cavitation.

High Pump Speed and Flow Restrictions

Operating at higher-than-rated speed or throttling on the suction side can drop suction pressure significantly, inducing cavitation.

Effects of Cavitation

Pitting and Erosion of Impeller and Casing

The micro-jets produced during bubble collapse can reach pressures up to 1000 MPa, enough to remove metal particles. Over time, this results in pitting, erosion, and reduced impeller thickness.

Noise and Vibration

Cavitation often sounds like gravel or marbles circulating within the pump. The collapsing bubbles produce a characteristic rattling sound, accompanied by strong vibrations.

Reduced Pump Efficiency and Capacity

As vapor bubbles occupy space inside the impeller, liquid flow and pressure drop. The pump may fail to achieve its design performance curve.

Structural Damage and Shortened Service Life

Continuous cavitation can loosen fasteners, damage bearings, and cause mechanical seal failure, leading to total pump breakdown.

Impact on System Reliability

A cavitating pump affects connected systems — pressure fluctuations can damage piping, valves, and downstream equipment.

How to Detect Cavitation

Audible Signs

Listen for distinct knocking, rattling, or gravel-like noises — early indicators that vapor bubbles are collapsing within the pump.

Performance Symptoms

Decrease in discharge pressure

Fluctuating flow rate

Rising vibration levels

Temperature increase at the suction

Vibration Analysis and Acoustic Monitoring

Modern plants use vibration sensors and ultrasonic detectors to identify the unique frequency patterns of cavitation. Spectral analysis can differentiate between mechanical imbalance and cavitation.

Visual Inspection and Maintenance Data Trends

Regular inspection of impeller surfaces for pitting or roughness, along with reviewing maintenance logs, helps confirm chronic cavitation issues.

Prevention and Control Methods

Ensuring Proper NPSH Design and Monitoring

Always ensure that NPSHa ≥ NPSHr + safety margin (typically 0.5–1 m). This can be achieved by increasing suction head, lowering pump elevation, or reducing friction losses.

Reducing Suction Lift and Fluid Temperature

Placing pumps below the fluid source and avoiding hot liquids minimizes vapor formation risk.

Using Larger Suction Pipes and Smooth Fittings

A larger pipe diameter reduces velocity and friction loss, maintaining higher suction pressure. Avoid using sudden bends or throttling valves on the suction side.

Installing Air Release and Vacuum Breaker Valves

These valves prevent air pockets and maintain stable suction pressure, ensuring uniform flow to the impeller.

Using Inducers and Special Impeller Designs

Inducers — small axial-flow impellers — pre-pressurize the fluid entering the main impeller, reducing cavitation risk in high-speed applications.

Regular Inspection and Preventive Maintenance

Routine maintenance, alignment checks, and vibration monitoring ensure long-term cavitation-free operation.

Cavitation in Industrial Systems

Case Studies from Power Plants, Marine Systems, and Process Industries

In power plants, feedwater pumps experience cavitation due to high temperatures and low suction heads.

In marine applications, ballast pumps face cavitation when vessels roll and suction head fluctuates.

In chemical plants, improper pump selection for volatile liquids like hydrocarbons often leads to persistent cavitation.

Importance of Predictive Maintenance and Monitoring Technologies

Advanced predictive systems combine vibration, pressure, and acoustic data to detect cavitation before visible damage occurs — reducing unplanned downtime.

Economic Impact of Cavitation Failures

Even minor cavitation can reduce pump efficiency by 10–15%, leading to thousands of dollars in annual energy losses, aside from repair costs and production interruptions.

FAQs

1. What is the most common cause of cavitation?

The most frequent cause is insufficient NPSH, often due to low suction pressure, high temperature, or poor suction design.

2. How do you fix a cavitating pump?

Increase suction head, lower pump elevation, use larger suction pipes, or reduce pump speed. Always ensure NPSHa > NPSHr.

3. What is NPSH and why is it important?

Net Positive Suction Head (NPSH) ensures that pressure at the pump inlet stays above vapor pressure, preventing vapor bubble formation.

4. Can cavitation be completely eliminated?

Not always — but it can be minimized through good system design, proper operating practices, and continuous monitoring.

Conclusion

Cavitation is one of the most common and destructive problems in centrifugal pumps. It begins silently — with a few vapor bubbles — but can end with severe damage, efficiency loss, and high maintenance costs.

The key lies in early detection, proper system design, and maintaining adequate NPSH. By following preventive measures such as correct suction design, monitoring pump performance, and using modern diagnostic tools, engineers can ensure long-lasting, efficient pump operation.

Cavitation may be invisible, but its effects are loud — both literally and financially.

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders