Flux-Cored Arc Welding: Self-Shielded vs Gas-Shielded

Welding is at the core of modern metal fabrication, making it possible to construct bridges, ships, skyscrapers, and pipelines. Among the numerous welding methods available today, Flux-Cored Arc Welding (FCAW) has carved a niche for itself, especially in heavy industrial sectors. This semi-automatic or automatic arc welding process utilizes a continuously fed tubular wire filled with flux, which allows for high deposition rates, deeper penetration, and improved out-of-position performance.

But here’s the thing: FCAW isn’t just one process—it branches into two primary variations:

Gas-Shielded FCAW (FCAW-G)

Each method has unique shielding mechanisms, applications, and equipment requirements. If you’re working in the welding field—or teaching others about it—it’s critical to understand these distinctions in detail.

What is Flux-Cored Arc Welding (FCAW)?

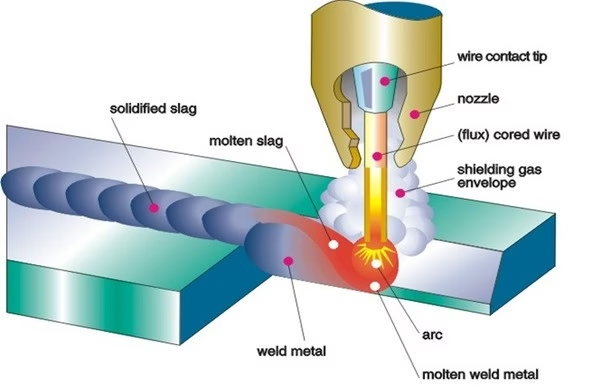

FCAW is a semi-automatic arc welding process that uses a tubular wire filled with flux, rather than the solid wire used in MIG (GMAW) welding. When an arc is struck between the wire electrode and the workpiece, the electrode melts, depositing filler metal into the joint. Simultaneously, the flux inside reacts to create protective gases and slag, shielding the weld pool from atmospheric contamination.

FCAW is commonly mistaken for MIG welding due to their similar equipment. However, unlike MIG, which relies on a solid wire and external shielding gas, FCAW’s strength lies in its internal flux core, which can either replace or complement the shielding gas.

Self-Shielded FCAW (FCAW-S)

How It Works

FCAW-S uses a tubular wire electrode with flux that produces all the shielding gases internally, making external shielding gas unnecessary. As the flux burns, it releases a protective gas cloud that surrounds the arc and weld pool.

Advantages

Great for outdoor welding: Wind won’t blow away your shielding gas—because there isn’t any!

Portable setup: No gas tanks to lug around.

Deeper penetration: Especially useful in thick section welds.

Higher tolerance for dirty/rusty surfaces: Excellent for field work.

Limitations

More spatter: You’ll be doing more cleanup.

Rougher weld appearance: May need grinding or finishing.

Slag inclusion risk: Needs good technique and slag removal between passes.

Typically DC electrode negative (DCEN): Limits machine compatibility.

Gas-Shielded FCAW (FCAW-G)

How It Works

Also known as dual-shield welding, FCAW-G uses a flux-cored wire AND an external shielding gas, usually CO₂ or a CO₂/argon mix, delivered through the welding gun. The result is superior arc control and cleaner welds.

Advantages

Higher deposition rates: Ideal for productivity in shops and manufacturing.

Cleaner, smoother welds: Less spatter and better bead appearance.

Better mechanical properties: Especially with low-alloy wires and specific gases.

Excellent for thicker metals: Produces strong, high-quality welds.

Limitations

Sensitive to wind: Not ideal for outdoor use unless protected.

Less portable: Requires gas tanks and regulators.

Higher setup cost: More gear involved.

FCAW-S vs FCAW-G

| Feature | FCAW-S | FCAW-G |

|---|---|---|

| Shielding | Internal flux gases only | Internal flux + external shielding gas |

| Best For | Fieldwork, construction, windy areas | Structural steel, manufacturing, shops |

| Gas Requirement | None | Required (CO₂ or CO₂/Argon mix) |

| Weld Appearance | Rougher, more slag | Cleaner, less slag |

| Spatter | More | Less |

| Portability | Very portable | Less portable |

| Out-of-Position Capability | Excellent with proper technique | Also good, depending on wire type |

| Initial Cost | Lower | Higher (requires gas setup) |

| FCAW-S Applications | FCAW-G Applications |

|---|---|

| Structural steel erection | Heavy equipment manufacturing |

| Shipbuilding (exterior panels) | Pressure vessels, boilers |

| Pipelines in remote areas | Automotive frame fabrication |

| Repair work in outdoor settings | General fabrication in industrial shops |

FAQs

Can you use the same flux-cored wire for both FCAW-S and FCAW-G?

No. The wire types are different. FCAW-S wires are designed to self-shield, while FCAW-G wires are optimized to work with external shielding gas.

Which FCAW method is better for vertical or overhead welding?

FCAW-S is often preferred for out-of-position welding due to its slag system and penetration profile, but some FCAW-G wires are also designed for all positions.

Is FCAW stronger than MIG?

In many structural and heavy fabrication applications, yes. FCAW typically offers deeper penetration and better mechanical properties in thicker materials.

What gases are used with FCAW-G?

Common choices are 100% CO₂ for deeper penetration and 75% Argon / 25% CO₂ for a cleaner arc and less spatter.

Do both FCAW processes produce slag?

Yes, both processes produce slag. However, FCAW-G generally produces less slag and allows for cleaner welds, while FCAW-S often results in heavier slag that must be carefully removed.

Conclusion

Flux-Cored Arc Welding is a powerful and adaptable process that offers two very distinct flavors—FCAW-S for field use and rugged conditions, and FCAW-G for clean, high-productivity shop environments. Both methods share the same core principle but diverge in shielding strategy, weld quality, and practical application.

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders