Understanding HAZ in Aluminum Welds

The Heat-Affected Zone (HAZ) is the unseen neighborhood around a weld where temperatures from the welding process change the metal’s microstructure without melting it. In aluminum welding the HAZ frequently controls whether a joint will meet strength, toughness, or corrosion requirements — more than the visible weld bead itself. This article explains what happens in the HAZ of aluminum, how it is subdivided, why aluminum alloys are especially sensitive to HAZ effects, how HFZ is used in the literature (and why that term can be ambiguous), and what welders and instructors should do to control or mitigate HAZ problems.

Basic definitions

What is the Heat-Affected Zone (HAZ)?

The Heat-Affected Zone (HAZ) is the region of base metal adjacent to the weld that did not melt but experienced temperatures high enough to alter its microstructure and properties. The HAZ begins where melting stops and extends outward until the thermal cycle no longer changes the metal. The size and character of the HAZ depend primarily on the base alloy, the welding heat input, and cooling rate.

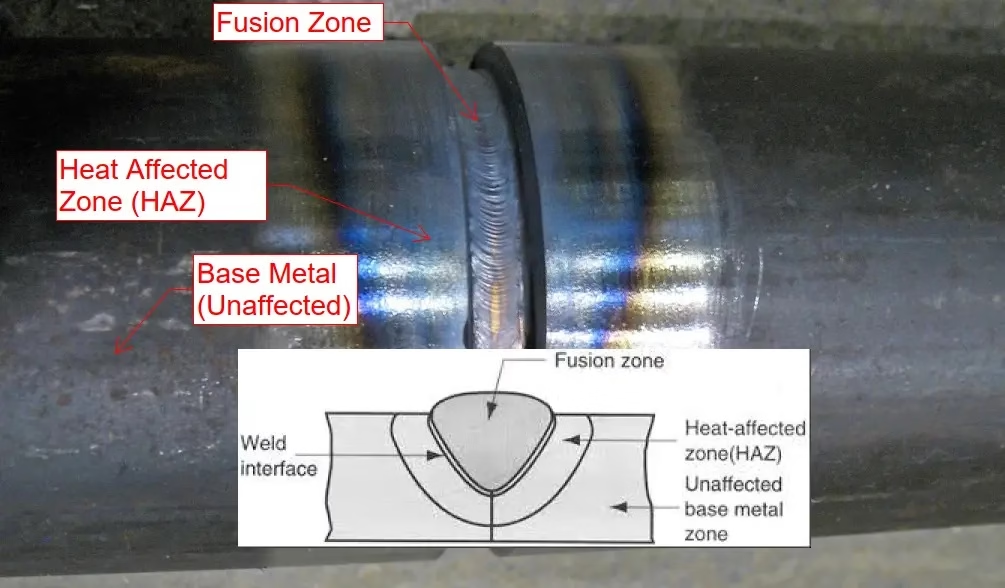

Fusion zone (FZ) vs HAZ vs base metal

A welded joint can be pictured as three concentric regions: the fusion zone (FZ or weld metal) where melting and solidification occurred; the HAZ where the base metal was thermally altered but not melted; and the unaffected base metal. The fusion zone’s microstructure depends mainly on the filler and solidification conditions; the HAZ’s microstructure depends mainly on the thermal cycle imposed on the parent metal.

The term “HFZ” — common meanings and ambiguity

You asked specifically about HFZ. That abbreviation is not a single universally accepted standard in welding textbooks. In practice HFZ sometimes appears in different contexts:

• As a shorthand for “heat/fusion zone” (i.e., the weld metal or fusion zone) in older lab manuals or some classroom notes.

• As “hard-face zone” or “hard face zone” in hardfacing literature where a wear-resistant layer creates a distinct microstructure.

• Occasionally as a process-specific abbreviation (authors sometimes use short variable names like hFZ for fusion zone thickness in research papers).

Because HFZ is ambiguous, the safer and clearer terms are Fusion Zone (FZ) or Weld Metal when referring to the melted and resolidified material; and HAZ when referring to the thermally altered, unmelted parent metal. When I use “HFZ” below I will explicitly state which meaning I adopt; whenever possible I’ll prefer FZ/Fusion Zone to avoid confusion. (See authoritative sources for HAZ/FZ distinctions above.)

Metallurgical changes that occur in aluminum HAZ

Aluminum alloys react to welding heat differently from steels because of their crystal structure, thermal conductivity, and — for many alloys — precipitation-hardening chemistry.

Grain growth and recrystallization

Near the weld the temperature can be high enough to cause grain growth or recrystallization in wrought aluminum. Grain coarsening reduces toughness and can change yield and tensile strength locally. Unlike steels, aluminum does not undergo phase changes (like austenite→martensite) in most commercial alloys, but thermally driven grain growth and dynamic recrystallization are important.

Dissolution and re-precipitation of strengthening phases (heat-treatable alloys)

Many high-strength aluminum alloys (notably the 2xxx, 6xxx and 7xxx series) owe strength to fine precipitates produced by controlled heat treatment and aging. Welding heats dissolve or coarsen those precipitates in the HAZ. On cooling, precipitates may re-form but usually in a coarser, less effective form — producing softened zones where tensile and yield strengths drop compared with the parent material. For many heat-treatable aluminum alloys the HAZ is essentially annealed by the weld thermal cycle.

Softened / overaged zones

The practical result for heat-treatable alloys is a softened HAZ whose mechanical strength can be significantly below the parent metal and sometimes even below the weld metal. This is why design and procedure writers treat HAZ control as the Achilles’ heel of aluminum welding: the weld’s load-carrying capacity is often limited by the HAZ, not the weld bead itself.

Standard sub-zones inside/around the HAZ

Welds are not uniform; as you move from the fusion line outward the peak temperature and the time at high temperature change continuously, generating recognizable sub-zones.

Fusion Zone (FZ) — the literal “melt”

The Fusion Zone (FZ) or weld metal is the melted and resolidified region created by fusion welding. In some classroom notes this is called a heat/fusion zone (HFZ) — but again, fusion zone or weld metal are clearer. The fusion zone typically has solidification structures (columnar near the fusion boundary, equiaxed in the bulk) and its mechanical properties depend on filler chemistry and cooling conditions.

Partially Melted Zone (PMZ)

Immediately adjacent to the fusion line you may see a Partially Melted Zone (PMZ) where grain boundaries reach melting temperatures even though the bulk did not. The PMZ is often a site for localized weakness or eutectic constituents that can reduce ductility.

Coarse-Grained HAZ (CGHAZ)

Closer to the fusion line, peak temperatures are highest (but still below melting) and grains can grow large — this coarse-grained HAZ often shows reduced toughness and may be a crack initiation site.

Fine-Grained HAZ (FGHAZ)

Farther from the weld the peak temperatures are lower and grain growth may be limited or reversed through recrystallization; this region is often called the fine-grained HAZ and can have better toughness than the coarse region. Researchers typically separate the HAZ into FGHAZ and CGHAZ to describe these gradients.

Softened / Overaged HAZ (precipitation-hardened alloys)

A particularly important “type” of HAZ in practical terms is the softened HAZ which results from the dissolution/coarsening of strengthening precipitates. The physical microstructure names above still apply, but in heat-treatable alloys the key descriptor is whether the HAZ is strength-reduced (softened) or not. ESAB and other sources emphasize that aluminum HAZs are frequently annealed by welding heat, and weld procedure qualification must account for the annealed strength of the alloy.

Special case — Solid-state processes (Friction Stir Welding)

Friction Stir Welding (FSW) is a different beast: it joins without melting, so the subzones are described differently.

Stir Zone (SZ) / dynamically recrystallized zone

The stir zone (also called the nugget or dynamically recrystallized zone) is where severe plastic deformation and frictional heat create very small, equiaxed grains — often stronger or tougher than the surrounding HAZ.

Thermo-mechanically Affected Zone (TMAZ)

Adjacent to the SZ is the TMAZ, where material has been deformed and heated but not fully recrystallized.

FSW HAZ

Beyond the TMAZ sits the HAZ proper: thermally altered without plastic deformation. In many aluminum alloys FSW reduces HAZ softening compared with fusion welding, because there is no melting and the thermal exposure can be more controlled. The classical FSW microstructural zonation (SZ, TMAZ, HAZ) is widely documented and is an attractive way to limit the detrimental HAZ effects in high-strength aluminum applications.

Mechanical and corrosion consequences of HAZ in aluminum

Strength loss and tensile behavior

Because welding can anneal or overage heat-treated alloys, the HAZ frequently becomes the weakest link in a joint. For design and inspection, the as-welded tensile capacity is often compared to the annealed strength of the base alloy — not the parent tempered strength — since the HAZ is effectively annealed by the weld heat.

Toughness and fatigue

Grain growth in the coarse-grained HAZ can reduce toughness and increase the propensity for crack initiation. HAZ softening also changes stress distributions and can reduce fatigue life if not properly managed by joint design, residual stress control, or post-weld treatments.

Corrosion susceptibility

Changes in microstructure and precipitate chemistry alter electrochemical behavior. In precipitation-hardened alloys the redistribution or dissolution of precipitates can create zones where intergranular corrosion or localized attack is more likely. Designers must account for HAZ corrosion susceptibility when welding pressure vessels, marine structures, or aircraft components.

How to inspect and characterize the HAZ

Macro-etching and optical microscopy

A standard way to examine HAZ zones is to section the weld, polish, and etch for macro- and microstructure. Macro-etch reveals the overall profile (FZ, PMZ, HAZ width), while optical microscopy at higher magnification reveals grain size and precipitate distributions.

Hardness mapping

A hardness traverse from weld centerline into the parent metal quickly shows softened or hardened regions; this is especially useful for heat-treatable aluminum where a drop in hardness in the HAZ signals loss of strength.

Mechanical testing and NDT

Tensile tests of welded specimens, bend tests, and fatigue testing are used for qualification. NDT such as dye-penetrant or ultrasonic inspections check for defects; however, microstructural HAZ issues (softening, precipitate loss) require metallurgical tests, not just conventional NDT.

How to control, reduce, or mitigate harmful HAZ effects

Welding process and heat-input control

Minimizing total heat input (J/mm) reduces the HAZ width and peak temperature in adjoining metal. Use fast travel speeds, lower currents, or processes with concentrated heat (laser, electron beam) to reduce HAZ size. For many aluminum applications, switching to a lower-heat input process or optimizing GMAW/CMT parameters can cut HAZ damage. The relationship between heat input, cooling rate, and HAZ extent is well established in welding engineering.

Filler metal choice and joint design

Select filler alloys that produce compatible mechanical properties and avoid creating weaker zones at the fusion interface. For example, 4xxx (Al-Si) fillers are often used for aluminum to reduce cracking and produce good bead wetting; 5xxx (Al-Mg) fillers give higher strength but different corrosion behavior. Joint geometry (thickness, fit-up) influences heat flow and therefore HAZ development.

Post-weld heat treatment and aging strategies

If the base alloy is heat-treatable, controlled post-weld heat treatments (solution treatment + artificial aging) can restore properties — but they require full part capability for heat treat (size limitations, distortion, and cost). For many welded structures restoration is impractical; instead qualification uses the annealed (as-welded) properties as the basis for design.

Use of solid-state joining and low-heat processes

Friction Stir Welding (FSW) or advanced cold-arc processes produce smaller or different HAZs and often preserve more parent-metal strength. For high-performance applications, choosing FSW or laser welding can be the most effective way to protect the HAZ.

Practical guidance for welders and instructors

Procedure tips for common aluminum alloys

• For 5xxx series (non-heat-treatable): HAZ softening is less a problem — focus on avoiding porosity and oxide contamination.

• For 6xxx and 7xxx series (heat-treatable): assume weld HAZ will be softened — either design for annealed strength or plan for post-weld heat treatment if feasible.

• Cleanliness matters more for aluminum than for many steels: remove oxides and contamination to avoid defects that can complicate HAZ performance.

Teaching demonstration ideas and common mistakes

Demonstrate a hardness traverse across a welded sample to show students the softened HAZ; visually etch a macrosection so students can see the FZ, PMZ, and HAZ widths; compare a fusion weld sample with an FSW sample of the same alloy to show how process choice changes the HAZ. Common instructor mistakes include failing to discuss precipitation effects in heat-treatable alloys and overstating the bead’s strength without examining the HAZ.

FAQs

What is the single most important control to reduce HAZ damage in aluminum welding?

Minimize and control heat input (J/mm) — faster travel speed, optimized current/voltage, and selecting lower-heat processes (or solid-state methods like FSW) reduce HAZ width and peak temperatures.

Does the HAZ always make aluminum weaker than the base metal?

Not always — non-heat-treatable alloys (e.g., many 5xxx series) are less affected by precipitate dissolution, but heat-treatable alloys (2xxx, 6xxx, 7xxx) usually show HAZ softening because weld heat dissolves strengthening precipitates.

How is HFZ different from FZ and HAZ?

HFZ is not a standardized abbreviation. Many engineers prefer FZ (Fusion Zone) to denote the melted weld metal, and HAZ for the thermally altered but unmelted parent metal. If you see HFZ, ask the author whether they mean fusion/weld metal or a different concept such as a hard-face zone.

Can post-weld heat treatment fully restore HAZ strength in precipitation-hardened aluminum?

In some cases yes — full solution treatment followed by controlled aging can restore properties, but this requires access to heat-treat equipment and can introduce distortion. For many welded assemblies it is impractical; therefore designers usually qualify welded joints to annealed (as-welded) properties.

Which inspection methods best reveal HAZ problems I should teach students?

Use macro-etching to show HAZ width and fusion boundaries, hardness traverses to map softening, and metallography to reveal grain growth and precipitate changes. Combine these with mechanical tests (tensile, bend) where possible — NDT finds defects but metallurgical tests reveal HAZ property changes.

Conclusion

Aluminum weld HAZs are where heat writes its signature into the parent metal: grain growth, precipitate dissolution, softening, and sometimes greater corrosion susceptibility. Because aluminum alloys behave differently depending on whether they are strain-hardened or precipitation-hardened, the HAZ can either be a minor cosmetic change or the decisive weakness in a joint. The term HFZ is ambiguous in literature and is best clarified every time you use it — usually replacing it with Fusion Zone (FZ) or Weld Metal for clarity. Controlling welding heat input, choosing appropriate filler metals, employing solid-state joining where practical, and using proper inspection and qualification procedures are the practical levers you and your students can use to manage HAZ behavior and produce reliable aluminum welds.

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders