What is a Hot Pass in Welding

Introduction

When it comes to welding, understanding the different passes and techniques is crucial for achieving high-quality welds. One such technique is the hot pass. So, what exactly is a hot pass in welding? In this article, we’ll delve into the details of hot pass, its importance, techniques, and applications. Let’s dive in!

Understanding the Welding Passes

To grasp the concept of a hot pass, it’s essential to understand the overall welding process. Welding involves joining two or more pieces of metal by melting and fusing them together. This process typically involves multiple passes, each with its own purpose and technique.

Overview of Welding Passes

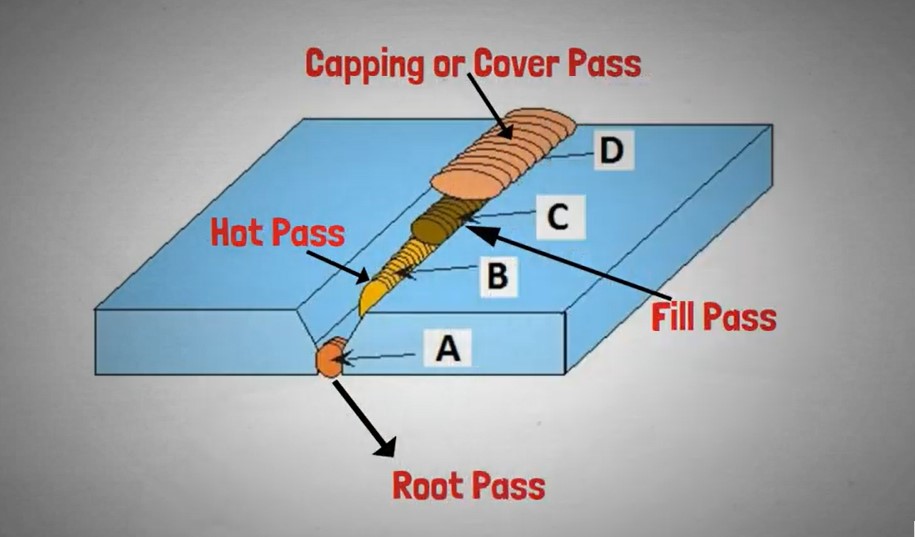

Welding passes refer to the layers of weld metal applied to the joint being welded. Each pass has a specific role in ensuring the strength, quality, and integrity of the weld. Common types of welding passes include the root pass, filler pass, and, of course, the hot pass.

Types of Welding Passes

- Root Pass: The initial pass that creates the foundation for subsequent weld layers.

- Filler Pass: Intermediate passes that fill the weld joint, providing strength and bulk.

- Hot Pass: A pass applied after the root pass to refine and strengthen the weld.

Defining Hot Pass

So, what exactly is a hot pass? In simple terms, a hot pass is a welding pass that follows the root pass. It’s done to refine and reinforce the weld, removing any slag or impurities left behind by the root pass and ensuring a clean and strong weld joint.

Characteristics of a Hot Pass

A hot pass is typically characterized by higher heat input compared to the root pass. This higher heat helps to burn away any slag or impurities, ensuring a clean and smooth weld surface. The hot pass also helps to fuse the root pass more effectively with the base metal, enhancing the overall strength of the weld.

Purpose of the Hot Pass

Why is a Hot Pass Important?

The hot pass plays a crucial role in ensuring the quality and integrity of the weld. By removing slag and impurities, it prevents defects such as slag inclusion and porosity, which can weaken the weld. Additionally, the hot pass helps to refine the weld profile, making it smoother and more aesthetically pleasing.

Benefits of Using a Hot Pass

- Improved Weld Quality: The hot pass enhances the overall quality of the weld by removing impurities and ensuring proper fusion.

- Increased Strength: By fusing the root pass more effectively with the base metal, the hot pass improves the strength and durability of the weld.

- Enhanced Appearance: The hot pass helps to create a smoother and more visually appealing weld profile.

Techniques for Performing a Hot Pass

Preparation for a Hot Pass

Preparation is key to a successful hot pass. Before starting, ensure that the root pass is free from slag and impurities. Proper cleaning and inspection are essential to avoid defects in the hot pass.

Execution of a Hot Pass

Executing a hot pass involves using a higher heat input compared to the root pass. This higher heat helps to burn away any remaining slag and impurities, ensuring a clean and strong weld. It’s important to maintain a steady and controlled motion to achieve uniform heat distribution and proper fusion.

Common Mistakes to Avoid

- Inadequate Cleaning: Failing to clean the root pass properly can result in slag inclusion and other defects in the hot pass.

- Incorrect Heat Input: Using too much or too little heat can affect the quality and strength of the hot pass.

- Inconsistent Motion: Inconsistent motion can lead to uneven heat distribution and improper fusion.

Applications of Hot Pass

Industries and Scenarios

The hot pass is commonly used in various industries and scenarios where high-quality and strong welds are required. Some of these include:

- Pipeline Welding: Ensuring strong and durable welds in pipelines to prevent leaks and failures.

- Structural Welding: Providing robust welds for structural components in construction and engineering.

- Shipbuilding: Enhancing the strength and integrity of welds in ship structures.

Types of Welds Using Hot Pass

Hot passes can be applied to various types of welds, including:

- Butt Welds: Joining two pieces of metal edge-to-edge.

- Fillet Welds: Joining two pieces of metal at an angle.

- Groove Welds: Welding into a groove between two pieces of metal.

Tools and Equipment

Necessary Tools and Equipment

Performing a hot pass requires specific tools and equipment, including:

- Welding Machine: Provides the necessary heat input for the hot pass.

- Electrodes: Used to create the arc and melt the metal.

- Protective Gear: Ensures the safety of the welder during the process.

Maintenance and Safety Tips

Regular maintenance of welding equipment is essential for performing a successful hot pass. Additionally, following safety protocols and using protective gear is crucial to prevent accidents and injuries.

Common Challenges and Solutions

Challenges Faced During Hot Pass

- Slag Inclusion: Slag trapped in the weld can weaken the joint.

- Porosity: Gas pockets in the weld can reduce its strength.

- Cracking: Improper fusion can lead to cracks in the weld.

Tips for Overcoming Challenges

- Proper Cleaning: Ensure thorough cleaning of the root pass before performing the hot pass.

- Controlled Heat Input: Use the appropriate heat input to avoid defects.

- Consistent Technique: Maintain a steady and controlled motion during the hot pass.

FAQs

What is the difference between a Hot Pass and a Root Pass?

The root pass is the initial weld pass that creates the foundation for subsequent layers, while the hot pass follows the root pass to refine and reinforce the weld.

How do I know if my Hot Pass is successful?

A successful hot pass will have a smooth, clean surface with no slag inclusion or porosity. Proper fusion with the root pass and base metal is also a sign of success.

Can a Hot Pass be performed on all types of metals?

While a hot pass can be performed on many types of metals, the specific techniques and parameters may vary depending on the metal being welded.

What are the common defects in a Hot Pass?

Common defects in a hot pass include slag inclusion, porosity, and cracking. Proper cleaning, controlled heat input, and consistent technique can help prevent these defects.

How often should welding equipment be maintained for performing a Hot Pass?

Regular maintenance of welding equipment is essential for performing a successful hot pass. This includes cleaning, inspection, and calibration to ensure optimal performance.

Conclusion

In conclusion, the hot pass is a critical step in the welding process, playing a vital role in ensuring the quality, strength, and integrity of the weld. By understanding its purpose, techniques, and applications, welders can achieve high-quality welds that meet industry standards. Whether you’re working on pipelines, structural components, or shipbuilding, mastering the hot pass is essential for successful welding.

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders