MIG Welding

Definition and Explanation of MIG Welding

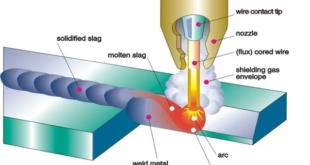

MIG welding, or Gas Metal Arc Welding (GMAW), is a widely used welding process that employs a continuous solid wire electrode as both the filler metal and the electrode. This wire is fed through a welding gun, and the arc is established between the electrode and the workpiece. Simultaneously, an inert gas, typically argon or a mix of argon and carbon dioxide, is emitted to shield the weld pool from atmospheric contaminants.

Equipment and Materials Used in MIG Welding

MIG welding requires specific equipment to facilitate the process. A welding machine with a power source, a wire feeder, a welding gun, and a shielding gas supply are essential components. The welding gun is equipped with a trigger, allowing the welder to control the wire feed and the power source. The electrode, typically a solid wire, and the shielding gas are selected based on the materials being welded and the desired welding characteristics.

Process of MIG Welding

Gas Selection and Its Role

The choice of shielding gas in MIG welding is critical to the success of the process. Inert gases like argon provide a stable arc and are suitable for welding non-ferrous metals such as aluminum. For welding ferrous metals like steel, a mix of argon and carbon dioxide is commonly used. The gas shields the molten weld pool from the atmosphere, preventing oxidation and ensuring a clean, strong weld.

Wire Selection and Its Impact on the Weld

The selection of the welding wire is influenced by factors such as the type of base metal, the welding position, and the desired mechanical properties of the weld. Solid wires are used for general-purpose welding, while flux-cored wires, which contain flux within the wire, are employed for welding in challenging conditions or on thicker materials.

Advantages of MIG Welding

MIG welding offers several advantages, making it a preferred choice in various applications. It is a high-speed process, enabling quick and efficient welding. The continuous wire feed results in less downtime, enhancing productivity. MIG welding also provides a clean and precise weld, reducing the need for extensive post-weld cleanup.

Limitations and Considerations

Despite its numerous benefits, MIG welding does have limitations. It may not be suitable for outdoor welding in windy conditions due to the sensitivity of the shielding gas. Additionally, MIG welding requires a stable power source, making it less portable compared to some other welding methods. Welders should also be mindful of the potential for burn-through on thin materials and adjust settings accordingly.

Stick Welding

Definition and Explanation of Stick Welding

Stick welding, formally known as Shielded Metal Arc Welding (SMAW), is a classic welding method widely utilized for its simplicity and versatility. In this process, an electrode, coated with a flux material, serves as both the filler metal and the electrode. The flux coating disintegrates during welding, creating a gaseous shield that protects the molten weld pool from atmospheric contaminants, such as oxygen and nitrogen.

Equipment and Materials Used in Stick Welding

Stick welding requires a minimalistic set of equipment, making it a popular choice in diverse environments. A welding machine with a power source, electrode holder (or stinger), and the consumable welding electrode are the primary tools. The welding electrode, often referred to as a “stick” or “rod,” comes in various types, each designed for specific applications and materials.

Process of Stick Welding

Electrode Selection and Its Impact on the Weld

The selection of the welding electrode is crucial in Stick welding. Different electrodes are tailored for specific materials and welding positions. Electrodes with specific coatings provide different arc characteristics, penetration levels, and shielding properties. Welders must choose the appropriate electrode based on the material being welded and the desired welding outcome.

Shielding Methods in Stick Welding

In Stick welding, the flux coating on the electrode plays a dual role. It not only facilitates the creation of a shielding gas to protect the weld pool but also provides a layer of slag. The slag helps cool the weld, adds alloying elements to the molten metal, and shields the weld from atmospheric contamination during solidification. After welding, the slag is chipped off to reveal the completed weld.

Advantages of Stick Welding

Stick welding boasts several advantages that contribute to its enduring popularity. Its simplicity makes it accessible to a wide range of welders, from beginners to seasoned professionals. Stick welding is highly portable, requiring minimal equipment, and is suitable for outdoor applications where other methods may face challenges. It excels in welding thick materials and is less sensitive to wind and environmental conditions compared to some other welding processes.

Limitations and Considerations

Despite its versatility, Stick welding does have limitations. It is generally slower compared to processes like MIG welding, and the need to periodically replace electrodes can result in downtime. The process may produce more spatter than some other welding methods, necessitating additional post-weld cleanup. Additionally, achieving high-quality welds may require more skill and practice, particularly when welding thin materials.

Key Differences Between MIG and Stick Welding

Welding Processes and Techniques

MIG Welding

MIG welding, or Gas Metal Arc Welding (GMAW), is a semi-automatic or automatic process where a continuous wire electrode is fed through a welding gun. The welder controls the wire feed speed and the power source, creating a clean and efficient weld. MIG welding is known for its high deposition rates and suitability for thin to medium-thickness materials.

Stick Welding

Stick welding, or Shielded Metal Arc Welding (SMAW), employs a consumable electrode with a flux coating. The welder manually strikes an arc, creating the heat needed for welding. Stick welding is characterized by its simplicity and versatility, making it suitable for various welding positions and environments. It excels in welding thick materials and is less dependent on a clean work surface.

Equipment and Materials

MIG Welding

MIG welding requires a welding machine with a power source, a wire feeder, a welding gun, and a shielding gas supply. The electrode used is a continuous wire, typically made of steel or aluminum. The choice of shielding gas and welding wire depends on the material being welded.

Stick Welding

Stick welding involves a simpler setup, requiring a welding machine with a power source and an electrode holder. The consumable electrode, or “stick,” comes with a flux coating that provides shielding and fluxing agents. Stick welding equipment is generally more portable and less complex than MIG welding equipment.

Applications and Industries Where Each Method is Preferred

MIG Welding

MIG welding is favored in industries that prioritize speed, precision, and cleanliness. It is commonly used in automotive, manufacturing, and construction for welding thin to medium-thickness materials. MIG welding is suitable for applications where efficiency and a neat appearance are essential.

Stick Welding

Stick welding finds applications in industries where versatility and robustness are paramount. It is widely used in construction, shipbuilding, pipeline welding, and maintenance repairs. Stick welding is valued for its ability to handle thicker materials, perform in outdoor and challenging conditions, and accommodate a variety of welding positions.

Skill Level Required for Each Method

MIG Welding

MIG welding is generally considered more user-friendly and requires less manual dexterity. It is suitable for beginners and can be quickly learned. The focus is on adjusting settings and controlling the welding gun.

Stick Welding

Stick welding demands a higher level of skill and control as the welder manually manages the arc and electrode. Achieving high-quality welds with Stick welding requires practice and experience. It is often considered a more traditional and hands-on approach to welding.

Advantages and Disadvantages

MIG Welding

Pros

Efficiency and Speed

MIG welding is known for its high deposition rates, allowing for rapid welding and increased productivity. The continuous wire feed minimizes the need for frequent stops and starts, enhancing efficiency.

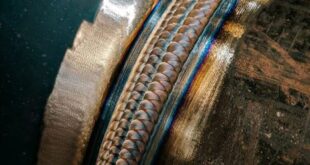

Clean and Precise Welds

MIG welding produces clean and aesthetically pleasing welds. The process is suitable for applications where a neat appearance is essential, such as automotive and sheet metal fabrication.

Versatility

MIG welding can be used on a variety of materials, including steel, aluminum, and stainless steel. The ability to weld different thicknesses makes it versatile for a wide range of applications.

Cons

Sensitivity to Wind and Weather

MIG welding is sensitive to wind and environmental conditions, particularly when using shielding gas. Outdoor welding in windy conditions can lead to gas dispersion, affecting the quality of the weld.

Equipment Complexity

The equipment for MIG welding can be more complex compared to some other welding methods. This may result in higher setup costs and a less portable welding setup.

Stick Welding

Pros

Versatility in Environments

Stick welding excels in diverse environments, including outdoor and challenging conditions. The flux coating on the electrode provides its shielding, making it less sensitive to wind and atmospheric conditions.

Portability

Stick welding equipment is generally more portable and requires fewer components. This makes Stick welding suitable for on-site projects and locations where mobility is essential.

Suitable for Thick Materials

Stick welding is well-suited for welding thicker materials, making it a preferred choice in industries such as construction and shipbuilding.

Cons

Slower Welding Speed

Stick welding is typically slower compared to processes like MIG welding. The manual nature of striking the arc and moving the electrode contributes to a slower welding speed.

Post-Weld Cleanup

Stick welding may produce more spatter compared to MIG welding, leading to additional post-weld cleanup. The removal of slag after welding is an integral part of the process.

Skill Requirement

Achieving high-quality welds with Stick welding requires a higher level of skill and practice. The manual control of the arc and electrode demands a steadier hand and greater welding expertise.

Choosing the Right Method for the Job

Factors Influencing the Choice Between MIG and Stick Welding

When faced with the decision of whether to use MIG welding or Stick welding for a particular job, several factors come into play. The following considerations can help guide welders in making an informed choice:

Material Type and Thickness

MIG Welding:

- Advantages: Well-suited for welding thinner materials, especially non-ferrous metals like aluminum. Provides clean and precise welds on a variety of materials.

- Considerations: May not be as effective on extremely thick materials due to limitations in penetration.

Stick Welding:

- Advantages: Excels in welding thicker materials and is versatile across various metal types. The manual nature allows for better control over penetration.

- Considerations: Can be less suitable for thin materials, and achieving the same level of precision as MIG welding may require more skill.

Welding Position

MIG Welding:

- Advantages: Particularly effective in flat and horizontal welding positions. Can be used in other positions with proper adjustments, but may be less convenient for vertical or overhead welding.

- Considerations: Welders may need to adapt techniques for different positions, and positional welds might require additional support.

Stick Welding:

- Advantages: Highly versatile in various welding positions, including vertical and overhead. The stick electrode allows for greater control in challenging orientations.

- Considerations: While more versatile, vertical and overhead welding may require additional skill and technique adjustments.

Skill Level of the Welder

MIG Welding:

- Advantages: Generally considered more user-friendly and suitable for beginners. Learning curve is often shorter, making it accessible to welders with varying skill levels.

- Considerations: Mastery of settings and techniques is essential for optimal results, but the initial learning process is often quicker.

Stick Welding:

- Advantages: Requires a higher level of skill due to manual control of the arc and electrode. Well-suited for experienced welders seeking greater control and precision.

- Considerations: Novice welders may find the initial learning curve steeper, requiring more practice to achieve proficiency.

Project Requirements and Specifications

MIG Welding:

- Advantages: Ideal for projects where speed and efficiency are critical, and a clean, professional appearance is desired. Well-suited for manufacturing, automotive, and sheet metal applications.

- Considerations: May not be the best choice for projects with stringent thickness or penetration requirements.

Stick Welding:

- Advantages: Excellent for projects requiring versatility, durability, and the ability to handle varying environmental conditions. Commonly used in construction, shipbuilding, and pipeline welding.

- Considerations: Slower welding speed may be a consideration for projects with time constraints.

FAQs

Is stick welding better than MIG?

It depends on the specific job requirements. Stick welding is often preferred for versatility in challenging environments and thicker materials, while MIG welding is efficient and offers cleaner welds, suitable for thinner materials and applications where appearance matters.

Can a stick welder be used for MIG?

No, a stick welder is not typically suitable for MIG welding without modifications. MIG welding requires different equipment, including a wire feeder, welding gun, and shielding gas supply.

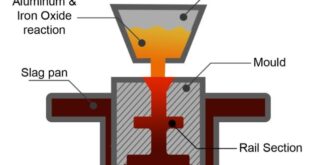

What type of welding is strongest?

The strength of a weld depends on factors like materials and joint configurations. Generally, Tungsten Inert Gas (TIG) welding is considered strong, especially for materials like stainless steel and aluminum, due to its precise control.

What is MIG welding not good for?

MIG welding may not be ideal for very thick materials or applications in windy conditions. Its sensitivity to wind can affect shielding gas coverage, impacting the quality of the weld.

Is stick welding hotter than MIG?

Yes, stick welding is often considered hotter than MIG welding. The manual control of the arc and the consumable electrode contribute to higher temperatures.

What is stick welder best for?

Stick welding is best suited for applications requiring versatility, durability, and the ability to weld in various environments. It excels in welding thicker materials and is commonly used in construction, shipbuilding, and pipeline welding.

Conclusion

The world of welding offers a spectrum of possibilities, and the choice between MIG and Stick welding is just one facet of this dynamic field. By recognizing the nuances of each method, appreciating their strengths and limitations, and investing in ongoing education, welders can elevate their expertise and contribute to the advancement of welding practices across various industries.

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders