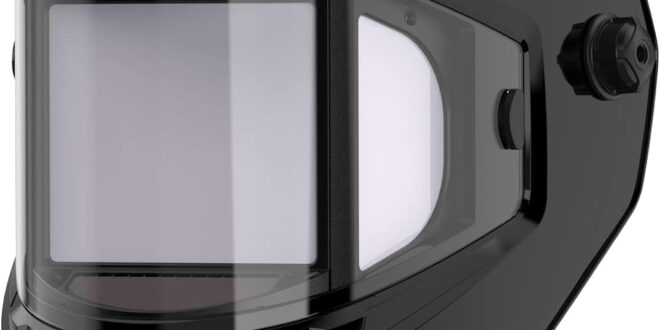

YESWELDER LYG-19800G Auto Darkening Welding Helmet Introduction: The YESWELDER LYG-19800G Auto Darkening Welding Helmet combines cutting-edge technology with ergonomic design to deliver exceptional performance and comfort for welders. With its panoramic view, True Color optics, and advanced features, it stands out as a top choice in the realm of welding …

Read More »

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders