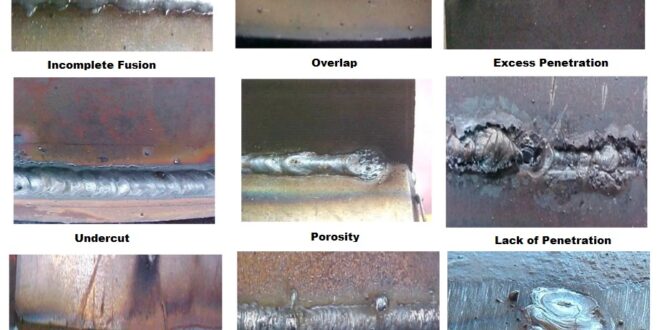

Common Welding Failures Introduction Welding is a fundamental process in manufacturing and construction, crucial for joining metals and creating structures of all kinds. However, despite its widespread use and importance, welding is not immune to failures. These failures, also known as welding defects, can compromise the integrity, strength, and safety …

Read More »

Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders