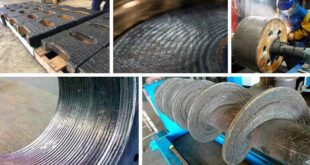

Tungsten Carbide Hardfacing and Welding Introduction The field of metallurgy and material science has witnessed remarkable advancements, and one such innovation that has garnered significant attention is Tungsten Carbide Hardfacing. This technique involves applying a layer of tungsten carbide, a robust and wear-resistant material, onto the surface of a substrate, …

Read More »Knife-Line Attack in Stainless Steel

Knife-Line Attack in Stainless Steel Knife-Line Attack is a form of corrosion that can weaken Stainless Steel structures and components. It is characterized by the development of thin cracks along the grain boundaries of the material. These cracks can significantly reduce the strength of the steel and, if not controlled, …

Read More »Welding Consumables: Everything You Need to Know

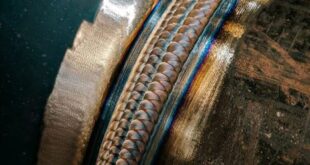

Welding Consumables: Everything You Need to Know Introduction Welding is an essential process in various industries, enabling the fabrication and repair of metal structures. One crucial aspect of welding is the use of welding consumables. These materials play a pivotal role in achieving high-quality welds and ensuring the durability of …

Read More »Welding Techniques for Cast Iron

Welding Techniques for Cast Iron Introduction Welding is a fundamental process in the world of manufacturing and construction, enabling the joining of diverse materials to create robust and intricate structures. Among the various materials that welders encounter, cast iron holds a unique position due to its distinct properties and challenges …

Read More »Optimization of Welding Process

Optimization of Welding Process Introduction Welding process optimization refers to the systematic improvement of welding operations to enhance productivity, quality, efficiency, and cost-effectiveness. It involves analyzing various factors, such as material properties, joint design, welding parameters, and environmental conditions, to achieve optimal welding results. Optimizing welding processes is crucial for …

Read More »Radiography Testing (RT)- NDT Inspection

Radiography Testing (RT)- NDT Inspection Introduction Radiography Testing (RT) is a non-destructive testing (NDT) method used in welding to inspect and evaluate the quality of welds. It involves the use of X-rays or gamma rays to create images of the internal structure of the welded components. The purpose of this …

Read More » Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders