Slag Inclusions in Welding: Ensuring Seamless Joints Welding, a crucial process in various industries, is not without its challenges. One common issue that welders encounter is the presence of slag inclusions. This article dives deep into the world of welding, exploring what slag inclusions are, their impact on weld quality, …

Read More »Welding Failures

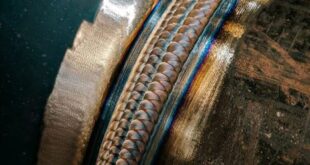

Common Welding Failures Introduction Welding is a fundamental process in manufacturing and construction, crucial for joining metals and creating structures of all kinds. However, despite its widespread use and importance, welding is not immune to failures. These failures, also known as welding defects, can compromise the integrity, strength, and safety …

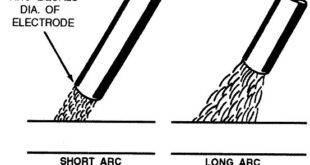

Read More »What is Arc Length Control?

Proper arc length control Welding is a fundamental process in metal fabrication, joining two or more materials to create a strong and durable bond. One crucial aspect of welding that significantly influences the quality of the weld is the arc length. In this article, we will explore the definition of …

Read More »Optimization of Welding Process

Optimization of Welding Process Introduction Welding process optimization refers to the systematic improvement of welding operations to enhance productivity, quality, efficiency, and cost-effectiveness. It involves analyzing various factors, such as material properties, joint design, welding parameters, and environmental conditions, to achieve optimal welding results. Optimizing welding processes is crucial for …

Read More » Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders