Internal Welding Defects Welding is a critical process in various industries, ensuring the structural integrity of assembled components. However, even in the hands of skilled welders, internal welding defects can compromise the quality of the welds, leading to potential hazards and failures. Introduction In the realm of welding, understanding internal …

Read More »Welding Copper and Copper Alloys

Welding Techniques for Copper and Copper Alloys Introduction Copper and its alloys are welded using various methods tailored to specific needs. Tungsten Inert Gas (TIG) welding ensures precision, making it ideal for thin copper sections, while Gas Metal Arc Welding (GMAW) or MIG welding is preferred for thicker components due …

Read More »Leak Testing for Welds

Leak Testing for Welds: Ensuring Quality and Safety Introduction In the intricate world of welding, ensuring the integrity of welds is paramount. One crucial aspect of this assurance is leak testing, a process designed to detect any imperfections or vulnerabilities in welded structures. [ads] Importance of Leak Testing Leak testing …

Read More »Weldability of Annealed, Normalized, Quenched and Tempered Materials

Weldability of Annealed, Normalized, Quenched and Tempered Materials Introduction Weldability is a crucial aspect in the realm of materials engineering and fabrication, representing the ability of a material to be welded under specific conditions without compromising its structural integrity. This property is of paramount importance in various industries, influencing the …

Read More »Partially Melted Zone in Aluminum

Partially Melted Zone in Aluminum Welding Welding is both an art and a science, especially when it comes to working with aluminum. The partially melted zone, a crucial aspect of the welding process, plays a pivotal role in determining the quality and strength of the final weld. In this comprehensive …

Read More »Welding Stress

Introduction Welding stress refers to the internal forces and strains that arise within a material during the welding process. As metals undergo heating and cooling cycles during welding, they experience changes in temperature and pressure that lead to the development of stresses within the welded structure. These stresses can significantly …

Read More »Tungsten Carbide Hardfacing and Welding

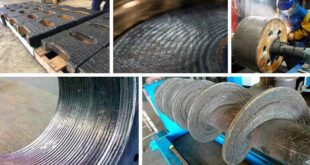

Tungsten Carbide Hardfacing and Welding Introduction The field of metallurgy and material science has witnessed remarkable advancements, and one such innovation that has garnered significant attention is Tungsten Carbide Hardfacing. This technique involves applying a layer of tungsten carbide, a robust and wear-resistant material, onto the surface of a substrate, …

Read More »Knife-Line Attack in Stainless Steel

Knife-Line Attack in Stainless Steel Knife-Line Attack is a form of corrosion that can weaken Stainless Steel structures and components. It is characterized by the development of thin cracks along the grain boundaries of the material. These cracks can significantly reduce the strength of the steel and, if not controlled, …

Read More »Welding Techniques for Lead

Welding Techniques for Lead: A Comprehensive Guide Lead is a heavy and soft metal that finds its use in various industries, including battery manufacturing, radiation shielding, and plumbing. Lead welding is a crucial skill in various industries, from construction to plumbing. Whether you’re a seasoned welder or just starting, understanding …

Read More »Robotic Welding in the Automotive Industry: Revolutionizing Manufacturing Processes

Robotic Welding in the Automotive Industry In the fast-paced world of automotive manufacturing, innovation and efficiency are paramount. Robotic welding, a groundbreaking technological advancement, has emerged as a game-changer in the industry. This article delves into the transformative impact of robotic welding in the automotive sector, examining its benefits, applications, …

Read More » Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders