How NOT TO Weld | MIG Welding Mistakes Introduction MIG welding, or Metal Inert Gas welding, is a preferred method for joining metals due to its speed, efficiency, and ease of learning. Despite its popularity, MIG welding is susceptible to numerous common errors. These mistakes can result in weak welds, …

Read More »Porosity in Welding

Introduction Welding is a critical process in metal fabrication, joining materials to create sturdy and reliable structures. However, like any manufacturing process, welding is not without its challenges. One of the persistent issues faced by welders is porosity. Understanding porosity in welding is crucial for ensuring the quality and integrity …

Read More »Undercut in Welding

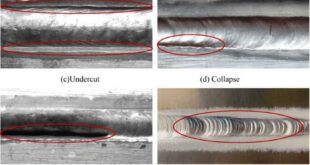

Unveiling the Undercut in Welding Welding, a crucial industrial process, is not without its challenges. One such challenge that often goes unnoticed but can significantly compromise weld integrity is “undercut.” In this article, we’ll dive deep into the world of undercut in welding, exploring its causes, identification methods, impact on …

Read More »Welding Defects and their Types

Welding Defects and their Types Introduction Welding defects are unacceptable imperfections that occur during the welding process. Weld quality depends on the mechanical properties of the materials, it can be quantitative or qualitative. Mostly “fit-for-service” approach is used i.e., the fabricated weld can perform the intended service. But in some …

Read More » Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders