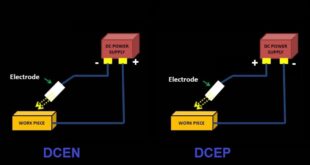

DCEN and DCEP Polarities In Welding Introduction Definition of DCEN and DCEP polarities in welding In welding, polarity refers to the direction of electrical current flow between the electrode and the workpiece. DCEN, or Direct Current Electrode Negative, means that the electrode is connected to the negative terminal of the …

Read More »Optimization of Welding Process

Optimization of Welding Process Introduction Welding process optimization refers to the systematic improvement of welding operations to enhance productivity, quality, efficiency, and cost-effectiveness. It involves analyzing various factors, such as material properties, joint design, welding parameters, and environmental conditions, to achieve optimal welding results. Optimizing welding processes is crucial for …

Read More »Welding Temperatures Guideline

Welding Temperatures Guideline Introduction Controlling welding temperatures is of utmost importance in ensuring the quality and integrity of welds. The temperature at which welding takes place plays a significant role in determining the mechanical properties, metallurgical characteristics, and overall performance of the welded joint. Failure to control welding temperatures can …

Read More »Ultrasonic Testing – NDT Inspection

Ultrasonic Testing – NDT Inspection Introduction Ultrasonic Testing (UT) is a non-destructive testing (NDT) technique widely used in the field of welding inspection. It involves the use of high-frequency sound waves to detect and evaluate defects in welds without causing any damage to the tested material. In the world of …

Read More »Introduction to Destructive Weld Testing

Introduction to Destructive Weld Testing: Ensuring Strong and Reliable Joints Introduction Welding is a vital process in various industries, from construction and manufacturing to automotive and aerospace. The quality and reliability of welded joints play a crucial role in ensuring the structural integrity and safety of the finished product. To …

Read More »WeldLogic Based Automatic Robot Welding

WeldLogic Based Automatic Welding Inrotech-WeldLogic Technology Inrotech-WeldLogic Technology is an advanced welding automation solution developed by Inrotech, a leading provider of robotic welding systems. Inrotech-WeldLogic Technology integrates cutting-edge software and hardware components to enhance the efficiency and precision of multipass welding processes. The technology combines intelligent welding process control, automated …

Read More »Welding Techniques for Thin Metal

Welding Techniques for Thin Metal Introduction Welding thin metal presents a unique set of challenges and considerations for welders. The delicate nature of thin metal requires specific techniques to ensure successful and reliable welds without distortion or burn-through. In this comprehensive guide, we will explore various welding techniques tailored for …

Read More »Welding Inspection Tools

Welding Inspection Tools Introduction Welding inspection tools play a crucial role in ensuring the quality and integrity of welds. They are essential for identifying defects, measuring dimensions, and verifying compliance with welding standards and specifications. These tools are designed to provide accurate and precise measurements, allowing inspectors to evaluate the …

Read More »What is CAD Welding?

What is CAD Welding? Introduction Definition of CAD Welding CAD Welding, also known as Computer-Aided Design Welding, refers to the application of computer-aided design and manufacturing techniques in the process of welding. It involves using CAD software to create a virtual model of the welding components, simulate the welding process, …

Read More »Upset Welding: Principles, Applications, and Advancements

Upset Welding: Principles, Applications, and Advancements Introduction Upset welding, also known as flash butt welding or resistance butt welding, is a solid-state welding process used to join two pieces of metal by applying pressure and heat to create a weld between them. It involves the controlled application of electric current …

Read More » Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders