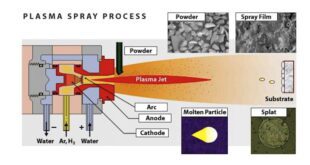

Plasma Arc Thermal Spraying Introduction Plasma arc spraying is a cutting-edge technology in the welding field, offering a robust solution for applying protective coatings to various materials. This process plays a critical role in enhancing the durability and performance of components in a wide range of industries. But what exactly …

Read More »Welding of High Tensile Strength Steel

Welding of High Tensile Strength Steel Introduction Welding high tensile strength steel is a critical task in numerous industries, from construction to automotive and aerospace. These materials, known for their exceptional strength and durability, require specialized welding techniques to maintain their integrity. In this article, we’ll dive into the intricacies …

Read More »What Causes Pinholes in Welding?

What Causes Pinholes in Welding? Introduction In the intricate world of welding, pinholes are a persistent challenge that welders encounter. These tiny voids, often invisible to the naked eye, can significantly compromise the integrity and quality of a weld. Understanding what pinholes are and why they need to be addressed …

Read More »Welding of Magnesium and its Alloys

Welding of Magnesium and its Alloys Introduction Magnesium, a lightweight and versatile metal, has found its place in numerous industries due to its exceptional properties. Its alloys, created by combining magnesium with other elements, further enhance its usability and performance in various applications. However, the welding of magnesium and its …

Read More »Resistance butt Welding

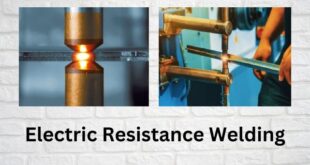

Introduction Resistance butt welding is a solid-state welding process wherein two metal workpieces are joined together by the application of heat and pressure. Unlike traditional fusion welding methods that involve melting the base metals, resistance butt welding relies on the generation of heat through electrical resistance at the interface of …

Read More »Slag Inclusions in Welding

Slag Inclusions in Welding: Ensuring Seamless Joints Welding, a crucial process in various industries, is not without its challenges. One common issue that welders encounter is the presence of slag inclusions. This article dives deep into the world of welding, exploring what slag inclusions are, their impact on weld quality, …

Read More »Welding Burn Through

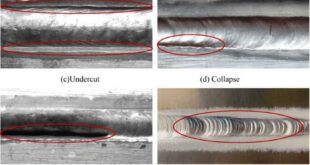

Welding Burn Through Causes & Prevention Introduction In the realm of welding, achieving strong and durable joints is paramount for ensuring the integrity and longevity of structures and components. However, despite meticulous attention to detail, welders often encounter various defects that compromise the quality of their work. One such common …

Read More »DEKO Digital 200A MIG/MMA Welder, SYNERGIC DC Inverter Welding Machine

DEKO Digital 200A MIG/MMA Welder, SYNERGIC DC Inverter Welding Machine Review Introduction The DEKO Digital 200A MIG/MMA Welder, SYNERGIC DC Inverter Welding Machine emerges as a robust welding solution suitable for both amateur enthusiasts and seasoned professionals alike. In this comprehensive review, we aim to dissect its features, performance, and …

Read More »Proper Ventilation for Welding

Proper Ventilation for Welding Introduction Welding is a vital process across industries, from construction to manufacturing. However, amidst the sparks and fumes, ensuring the safety and health of welders is paramount. Proper ventilation in welding plays a crucial role in creating a safe working environment, mitigating the risks associated with …

Read More »Welding Copper and Copper Alloys

Welding Techniques for Copper and Copper Alloys Introduction Copper and its alloys are welded using various methods tailored to specific needs. Tungsten Inert Gas (TIG) welding ensures precision, making it ideal for thin copper sections, while Gas Metal Arc Welding (GMAW) or MIG welding is preferred for thicker components due …

Read More » Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders