Welding vs Soldering vs Brazing Introduction When it comes to joining metals or other materials, there are several methods available, including welding, soldering, and brazing. Each technique has its own advantages and applications, and understanding the differences between them is crucial in choosing the right method for your project. In …

Read More »What is Percussion Welding?

What is Percussion Welding? Introduction Percussion welding is a specialized welding technique that involves the joining of two workpieces through the application of high pressure and electrical energy. It is a solid-state welding process, meaning that it does not involve the melting of the base metals. Instead, percussion welding relies …

Read More »What is CAD Welding?

What is CAD Welding? Introduction Definition of CAD Welding CAD Welding, also known as Computer-Aided Design Welding, refers to the application of computer-aided design and manufacturing techniques in the process of welding. It involves using CAD software to create a virtual model of the welding components, simulate the welding process, …

Read More »How to Choose the Right Welding Process for Your Project

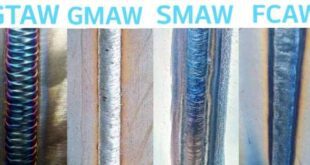

How to Choose the Right Welding Process for Your Project Introduction Selecting the appropriate welding process is a critical decision that directly affects the outcome of a welding project. With various welding techniques available, it is essential to understand the factors that influence the choice of welding process. By considering …

Read More »Self-Shielded Flux Cored Welding

Self-Shielded Flux Cored Welding Introduction Self-Shielded Flux Cored Welding is a welding process that uses a continuous, tubular electrode filled with flux to join two pieces of metal together. Unlike traditional welding methods, this process does not require an external shielding gas to protect the weld pool from atmospheric contamination. …

Read More »What is Argon Welding?

What is Argon Welding? Introduction Explanation of welding Welding is the process of joining two or more materials, typically metals, by melting and fusing them together. It is an important process used in various industries, including construction, manufacturing, and repair. Welding requires a heat source, filler material, and shielding gas …

Read More »Welding Electrodes and Filler Materials

Welding Electrodes and Filler Materials Introduction Welding is a widely used process in the manufacturing industry to join two or more metal parts together. It involves melting the base metal and adding a filler material to create a strong joint. One of the critical factors in welding is the choice …

Read More »Ferrous Vs Non-Ferrous Materials

Introduction Welding is a common industrial process that involves joining two or more materials to form a single piece. One of the most important considerations in welding is the selection of materials. Welding can be performed on a variety of materials, but they can be broadly classified into two categories …

Read More »AC vs DC Welding

AC vs DC Welding Introduction Welding is a fabrication process that joins two or more pieces of metal or thermoplastics by applying heat, pressure, or both. The process involves melting the base metal or filler material to create a joint that is as strong or stronger than the original material. …

Read More »MIG Vs MAG Welding

MIG Vs. MAG Welding Introduction Welding is a crucial process used in various industrial and manufacturing applications to join two or more metal parts. It involves heating the metal to its melting point and then fusing it together using a filler material. Among the different types of welding, MIG (Metal …

Read More » Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders