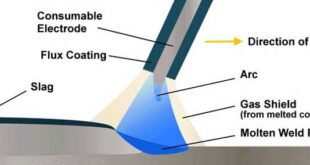

Shielded Metal Arc Welding (SMAW) AWS A5.1 – A5.5 Welding is a fundamental process used across various industries to join metals and create structures, and one of the most versatile methods in this domain is Shielded Metal Arc Welding (SMAW). SMAW, also known as “stick welding,” is a widely used …

Read More »11 Must-Follow Rules of Welding

11 Must-Follow Rules of Welding Introduction Importance of Adhering to Safety Rules in Welding Welding is a crucial and widely used technique in various industries, including construction, manufacturing, and automotive. While welding plays a vital role in creating strong and durable connections, it also poses inherent risks and hazards. Adhering …

Read More »Bare Metal Arc Welding: Crafting Strong Bonds through Precision

Bare Metal Arc Welding: Crafting Strong Bonds through Precision Introduction In the realm of metalworking, the art of welding stands as a cornerstone technique for joining metals seamlessly. Among the myriad of welding methods available, Bare Metal Arc Welding emerges as a tried-and-true method renowned for its precision, strength, and …

Read More »Welding Non-Ferrous Metals

Welding Non-Ferrous Metals: Techniques, Applications, and Challenges Introduction Welding is a critical manufacturing process that joins materials together to create strong and durable structures. While welding is often associated with ferrous metals like steel and iron, it is equally essential for non-ferrous metals, such as aluminum, copper, and titanium. Non-ferrous …

Read More »MIG vs TIG: Which One to Choose?

MIG vs TIG: Which One to Choose? Introduction Welding stands as one of the fundamental processes that underpin the modern world’s infrastructure and manufacturing landscape. From towering skyscrapers to intricate machinery, the art of joining metals has enabled the creation of structures and products that shape our daily lives. At …

Read More »Welding Positions: Test Positions vs. Actual Positions in Welding

Introduction In the world of welding, precision and technique are paramount. One crucial aspect that significantly affects welding quality is the choice between test positions and actual positions. These two terms might seem similar, but they hold distinct importance in welding practices. This comprehensive guide will delve into the differences, …

Read More »Visual Inspection for Welding – Ensuring Quality and Integrity

Visual Inspection for Welding Welding plays a pivotal role in industries ranging from construction to manufacturing, creating strong and durable joints that are crucial for the integrity of structures and products. Ensuring the quality of these welds is paramount, and one of the most fundamental methods to achieve this is …

Read More »What is Nuclear Welding?

What is Nuclear Welding? Introduction In the realm of high-stakes industries, few are as demanding and critical as nuclear power. The pursuit of harnessing nuclear energy for the betterment of society requires an unwavering commitment to safety, precision, and structural integrity. At the heart of this commitment lies the practice …

Read More »What is Oxy-Hydrogen Welding?

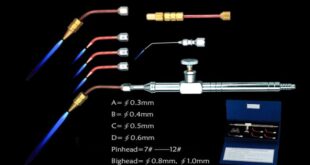

Oxy-Hydrogen Welding Introduction In the realm of modern manufacturing, technological advancements are continually reshaping the way we create, build, and innovate. Oxy-Hydrogen Welding, a cutting-edge technique that combines oxygen and hydrogen gases, has emerged as a revolutionary method of joining materials. This article delves deep into the world of Oxy-Hydrogen …

Read More »What is Welding Timer?

What is Welding Timer? Introduction Welding is a fundamental process used across various industries, from manufacturing to construction, to join metals and materials. Ensuring high-quality welds while maximizing productivity is crucial in these fields. One indispensable tool that contributes significantly to achieving this balance is the welding timer. In this …

Read More » Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders