Hybrid Welding Processes Introduction Hybrid welding processes involve the combination of two or more different welding techniques to leverage their respective advantages and achieve improved weld quality, productivity, and efficiency. These processes integrate different welding methods, such as arc welding (e.g., GMAW, SMAW) and other techniques like laser welding or …

Read More »Mold Tool and Die Repair Welding

Mold Tool and Die Repair Welding Introduction Overview of mold tool and die repair welding Mold tool and die repair welding is a specialized process used to restore and repair damaged molds and dies used in various industries, such as manufacturing, automotive, and aerospace. Welding techniques are employed to fix …

Read More »What is CMT Welding?

What is CMT Welding? Introduction Overview of welding as a vital manufacturing process: Welding is a fundamental process in the manufacturing industry that involves joining two or more metal pieces together to create a strong and durable bond. It plays a crucial role in various sectors, including automotive, aerospace, construction, …

Read More »Purge Welding vs Non-Purge Welding

Purge Welding vs. Non-Purge Welding Introduction Definition of purge welding Purge welding is a welding technique that involves creating a protective gas atmosphere around the weld zone during the welding process. This is typically achieved by introducing an inert gas, such as argon, to displace the surrounding air. The purpose …

Read More »Micro and Nano-scale Welding

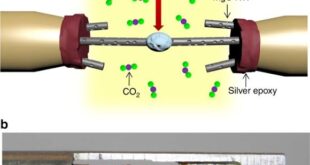

Micro and Nano-scale Welding Introduction Definition and Significance Micro and nano-scale welding refers to the process of joining or bonding materials at extremely small dimensions, typically in the range of micrometers (μm) to nanometers (nm). It involves the fusion of materials at a microscopic or nanoscopic level to create strong …

Read More »How to Weld Varying Diameter Pipes

How to Weld Varying Diameter Pipes Introduction Welding varying diameter pipes can be a challenging task that requires expertise and precision. Whether you’re working on a plumbing project, industrial construction, or any other application involving pipes, understanding the proper techniques for welding different pipe diameters / pipe welding is essential. …

Read More »Welding in the Oil and Gas Industry

Welding in the Oil and Gas Industry Introduction Welding plays a crucial role in the oil and gas industry due to its importance in the production and transportation of energy resources. The sector heavily relies on welding to ensure the integrity and reliability of various structures and equipment. Without welding, …

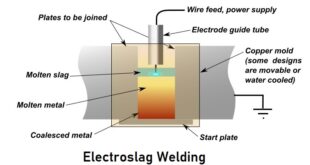

Read More »What is Electroslag Welding?

What is Electroslag Welding? Introduction Electroslag welding is a specialized welding process that offers numerous advantages in specific applications. In this comprehensive guide, we will delve into the intricacies of electroslag welding, exploring its definition, process, applications, benefits, limitations, and more. Whether you are a welding enthusiast, a professional welder, …

Read More »How to Weld Plastic?

How to Weld Plastic? Introduction Plastic welding plays a crucial role in various industries and applications. The ability to join plastic parts together effectively opens up a world of possibilities in fields such as manufacturing, automotive, construction, and even DIY projects. By understanding and mastering plastic welding techniques, individuals can …

Read More »How to Achieve a High Quality Welds

How to Achieve a High Quality Welds Introduction Welding is a critical process used in various industries to join metals together. Whether you’re a professional welder or a DIY enthusiast, achieving high-quality welds is essential for ensuring the structural integrity and longevity of your projects. In this comprehensive guide, we …

Read More » Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders