PRIMEWELD TIG225X AC/DC Tig/Stick Welder Review Introduction The PRIMEWELD TIG225X AC/DC Tig/Stick Welder is a highly versatile welding machine engineered to meet the demands of professional welders and hobbyists alike. In this comprehensive review, we will explore the machine’s key features, its performance across various welding processes, and its overall …

Read More »YESWELDER 135Amp MIG Welder Review

Introduction The YesWelder 135Amp MIG Welder emerges as a promising tool for welding enthusiasts and professionals alike. In this comprehensive review, we delve into its features, performance, and overall value proposition to aid prospective buyers in making an informed decision. Summary of the YesWelder 135Amp MIG Welder The YesWelder 135Amp …

Read More »Shielding Gas for MIG Welding

Shielding Gas for MIG Welding MIG welding, also known as Gas Metal Arc Welding (GMAW), is a widely used welding process in industrial and fabrication settings. It involves the use of a consumable electrode wire, which is continuously fed through a welding gun. The arc generated between the electrode wire …

Read More »ARCCAPTAIN MIG200 Multi Process MIG Welder Review

ARCCAPTAIN MIG200 Multi Process MIG Welder Review Introduction The ARCCAPTAIN MIG200 Multi Process MIG Welder is a versatile welding machine designed to cater to the needs of professionals and hobbyists alike. In this comprehensive review, we will delve into the machine’s key features, performance, and overall value proposition, providing valuable …

Read More »Electrogas Welding

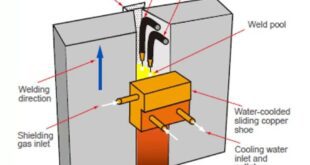

Electrogas Welding: Revolutionizing Industrial Welding Introduction Electrogas welding, also known as EGW, is a fusion welding process primarily used for thick materials, typically ranging from 1 inch to several inches in thickness. It involves the application of heat generated by electrical resistance to melt and join metals together, forming a …

Read More »Eastwood Elite TIG 200 LCD Review

Eastwood Elite TIG 200 LCD: Unveiling the Welding Powerhouse Introduction Welding enthusiasts, both novices and seasoned professionals, are always on the lookout for a welding machine that strikes a perfect balance between features, performance, and affordability. In this comprehensive review, we dive into the intricacies of the Eastwood Elite TIG …

Read More »Lincoln TIG 200 Square Wave Review

Review of the Lincoln Square Wave TIG 200: Is It Worth the Investment? Introduction: The Lincoln Square Wave TIG 200 is a well-known TIG welder in the market, catering to the needs of home hobbyists and light shop fabrication. In this comprehensive review, we will explore the machine’s key features, …

Read More »Welding Copper and Copper Alloys

Welding Techniques for Copper and Copper Alloys Introduction Copper and its alloys are welded using various methods tailored to specific needs. Tungsten Inert Gas (TIG) welding ensures precision, making it ideal for thin copper sections, while Gas Metal Arc Welding (GMAW) or MIG welding is preferred for thicker components due …

Read More »Offshore vs Onshore Welding

Offshore vs Onshore Welding Introduction Welding plays a crucial role in the construction, maintenance, and repair of structures across various industries. Whether it’s the fabrication of pipelines, construction of infrastructure, or maintenance of industrial facilities, welding is a fundamental process that ensures the integrity and durability of metal structures. However, …

Read More »What is High Frequency Welding?

What is High Frequency Welding? Introduction High-frequency welding is a specialized welding process that utilizes electromagnetic waves to join materials. This advanced technique has gained prominence in various industries due to its efficiency, precision, and versatility. Understanding the fundamentals of high-frequency welding is crucial to appreciate its significance in modern …

Read More » Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders