Weldability of Annealed, Normalized, Quenched and Tempered Materials Introduction Weldability is a crucial aspect in the realm of materials engineering and fabrication, representing the ability of a material to be welded under specific conditions without compromising its structural integrity. This property is of paramount importance in various industries, influencing the …

Read More »Arc Length, Weld Speed and Welding Current

Introduction Welding is a complex and intricate process that involves the fusion of materials to create strong and durable bonds. Within the realm of welding, three critical parameters significantly influence the quality of the weld: Arc Length, Weld Speed, and Welding Current. Understanding these factors is crucial for welders and …

Read More »Welding Thin Pipes and Tubes

Welding Thin Pipes and Tubes: A Comprehensive Guide Introduction Welding thin pipes and tubes requires a unique set of skills and techniques to ensure a strong and reliable bond. Whether you’re a seasoned welder or just starting in the world of welding, this guide will provide you with valuable insights …

Read More »Planar Defects in Welding

Planar Defects in Welding: Ensuring Strong, Flawless Joints Welding is a critical process in the fabrication of various structures, and while it provides strength and durability, it’s not immune to imperfections. Planar defects in welding can compromise the integrity of joints, leading to structural issues and reduced service life. In …

Read More »Partially Melted Zone in Aluminum

Partially Melted Zone in Aluminum Welding Welding is both an art and a science, especially when it comes to working with aluminum. The partially melted zone, a crucial aspect of the welding process, plays a pivotal role in determining the quality and strength of the final weld. In this comprehensive …

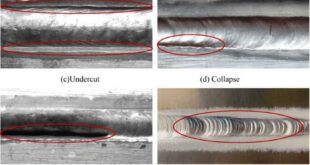

Read More »Undercut in Welding

Unveiling the Undercut in Welding Welding, a crucial industrial process, is not without its challenges. One such challenge that often goes unnoticed but can significantly compromise weld integrity is “undercut.” In this article, we’ll dive deep into the world of undercut in welding, exploring its causes, identification methods, impact on …

Read More »Tips for out-of-position welding

Tips for out-of-position welding Introduction Welding is a versatile skill that forms the backbone of numerous industries, contributing to the creation of structures and products that shape our world. Within the realm of welding, mastering the art of out-of-position welding is a crucial aspect that separates the novice from the …

Read More »Different Types of Iron and Their Weldability

Different Types of Iron and Their Weldability Introduction Iron plays a pivotal role in a multitude of industries, serving as a fundamental building block for countless applications. From construction to manufacturing, transportation to infrastructure, the versatility of iron makes it an indispensable material. Understanding the weldability of different types of …

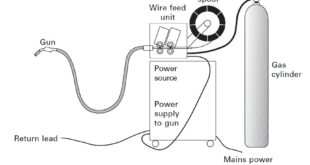

Read More »Tubular Cored Wire Welding

Tubular Cored Wire Welding Introduction The welding industry has witnessed significant advancements in technology, and one notable innovation that has gained prominence is Tubular Cored Wire Welding. This method represents a sophisticated approach to joining metals, offering distinct advantages over traditional welding techniques. Definition Tubular cored wire welding is a …

Read More »Hot Wedge Welding

Hot Wedge Welding: Applications, Functionality, Materials, and Safety Introduction: Hot Wedge Welding (HW) is a versatile and efficient welding technique widely employed in various industries. This ultimate guide aims to provide comprehensive insights into the uses, functionality, materials, and safety considerations associated with Hot Wedge Welding. Overview of Hot Wedge …

Read More » Welding of Welders All about Welding and Welders

Welding of Welders All about Welding and Welders